Prefabricated granite, or “prefab” granite, refers to granite countertops that are pre-cut and pre-finished in a factory before being shipped for installation. Unlike traditional slab granite, which is sold in large, raw pieces and requires on-site cutting and finishing, prefabricated granite is a hassle free alternative, designed for quick and easy installation with minimal adjustments

- Prefabricated Granite Vs Granite Slab

- Manufacturing Process of Prefabricated Granite

- Key Features of Prefabricated Granite

- Advantages of Prefabricated Granite

- Drawbacks of Prefabricated Granite

- When to Choose Prefabricated Granite

- Why is Prefabricated Granite Less Expensive?

- Are Prefab Granite Counters Made from Leftover or Cheap Remnants?

- Are Prefab Granite Counters Suitable for Small Projects, or Can They be Used in Big Scale Installations too?

- Will Prefabricated Granite Countertops Elevate my Home Value as Much as Slab Granite?

- Conclusion

- Frequently Asked Questions

Granite is a popular choice for countertops amongst buyers due to its durability, aesthetic appeal, and natural beauty. Among the various options available, prefabricated granite has emerged as a convenient and cost-effective alternative to traditional slab granite. This article explores what prefabricated granite is, its features, benefits, drawbacks, and compares it with custom-cut granite.

Prefabricated Granite Vs Granite Slab

| Feature | Prefabricated Granite | Slab Granite |

|---|---|---|

| Cost | Generally lower due to mass production | Higher due to custom cutting |

| Installation Time | Quick installation (often within a day) | Longer due to templating and cutting |

| Customization | Limited color and style options | Highly customizable in color and design |

| Quality | Varies; may include lower-quality materials | Typically higher quality |

| Seam Visibility | More seams possible due to size limits | Fewer seams; can be cut to fit perfectly |

| Environmental Impact | Higher carbon footprint from overseas shipping | Can be sourced locally |

Manufacturing Process of Prefabricated Granite

Prefabricated granite is crafted from natural stone, with certain fabrication processes prior to shipping. This mass-production approach lowers manufacturing costs, making it a more budget-friendly alternative to custom-cut slabs. The production of prefabricated granite involves the following steps:

Extraction:

The first step, extraction involves granite being quarried from natural stone deposits around the world.

Cutting:

Next, large granite blocks are cut into manageable slabs using advanced machinery.

Prefabrication:

After cutting, the slabs are then cut to standard sizes, polished, and finished with edges (often a bullnose edge) before being packaged for shipping.

Packaging:

The packaging of prefabricated granite is a crucial aspect for ensuring its safe transportation. It involves the following:

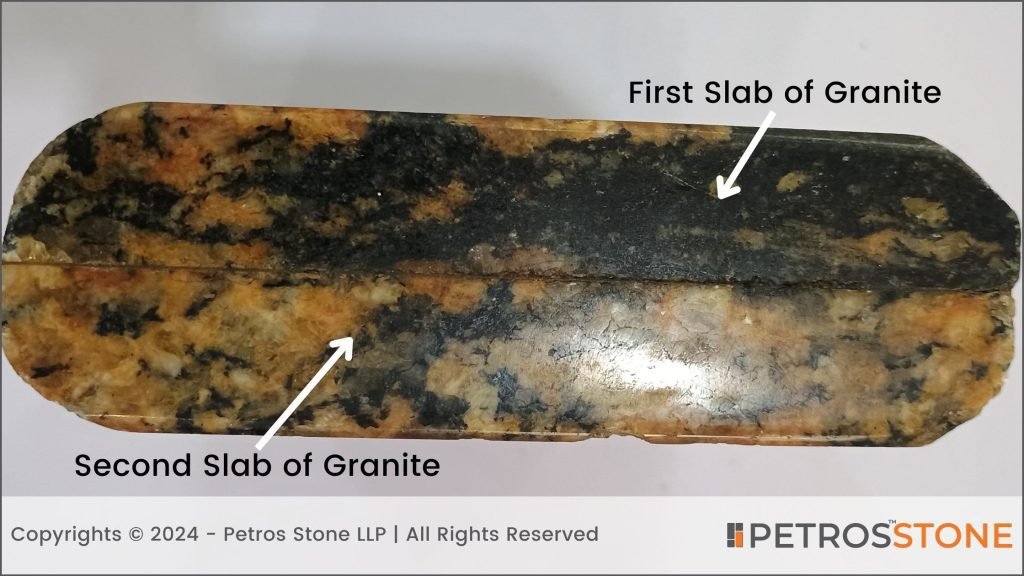

- Pallet Packing: Granite tiles are arranged on wooden pallets with polished sides facing each other, which are separated by soft paper or polythene to reduce friction.

- Wooden Crates: Tiles and slabs are packed in fumigated wooden crates which are secured with iron or plastic straps to prevent movement and damage during transit.

- Cushioning Materials: Foam, thermocol, or polystyrene sheets are used to protect surfaces from scratches and moisture.

- Marking: Each crate is labeled with essential details like material type, dimensions, and quantity for easy identification.

Shipping:

Finally, the prefabricated granite is transported to retailers or directly to customers, ready for installation.

Key Features of Prefabricated Granite

Standard Sizes: Prefabricated granite typically comes in standard dimensions, such as 112 inches by 26 inches (about 2.84m x 0.66m) and 108 inches by 42 inches (about 2.74m x 1.07m), making it suitable for both kitchen and bathroom layouts.

Edge Finishing: Most prefabricated countertops feature a bullnose edge or other standard edge profiles that enhance their aesthetic appeal.

Backsplash Inclusion: Many prefabricated granite options come with matching backsplashes included, usually around 6 inches high.

Advantages of Prefabricated Granite

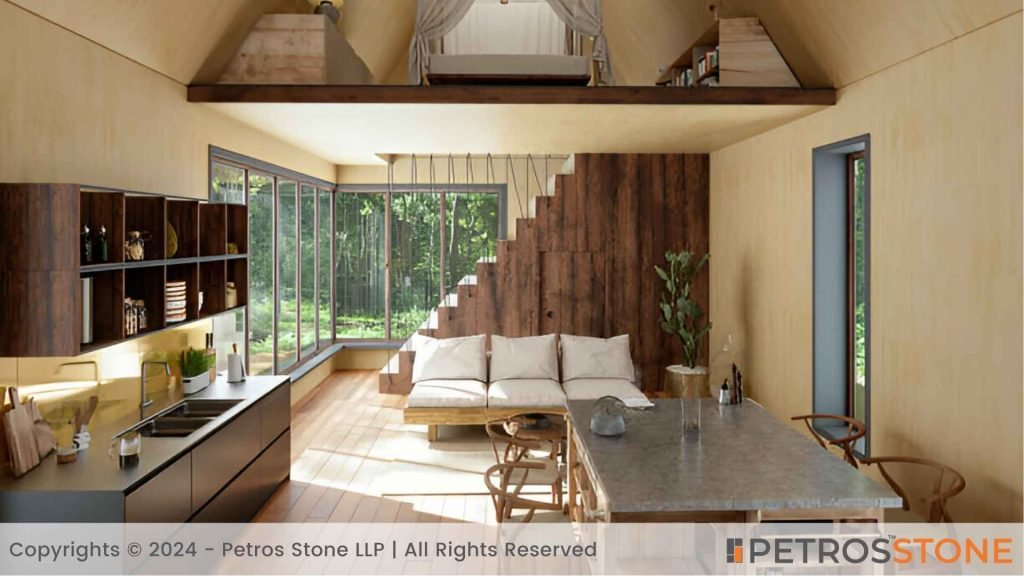

Do you want to give your kitchen or bathroom a fresh look without breaking the bank?

Then, Prefabricated granite countertops could be your best option. These countertops are not only super easy to install, but also come with a modern vibe and classic styles. Here are some reasons as to why these countertops might be the perfect fit for your home makeover:

Precision Manufactured:

Precision manufacturing of prefabricated granite involves a systematic process that ensures high-quality results. The following steps are involved:

- Mass Production: Prefabricated granite is cut and finished in bulk which produces standard sizes and shapes and also reduces waste and labor costs.

- Factory Processing: Granite is polished and edged in a controlled environment which ensures uniformity in thickness (typically 20mm) and edge style (usually a laminated flat edge) across all pieces.

- Quality Control: Rigorous quality checks are performed to ensure that each slab meets industry standards and is at par with aesthetics and structural integrity.

This method not only enhances efficiency but also maintains the natural beauty of granite. Thus, making it suitable for both residential and commercial applications.

Cost-Effectiveness:

- Prefabricated granite is less expensive than custom-cut slabs due to mass production and reduced labor costs associated with on-site fabrication.

- Alongside this with prefabricated granite homeowners can achieve the look of natural stone without the higher price tag usually associated with custom options.

Quick Installation:

- The pre-cut nature of prefabricated granite allows for faster installation compared to traditional slabs, which require templating and cutting on-site.

- Installers can often complete the job within a day, therefore minimizing disruption in the home.

Durability:

- Prefabricated granite retains the same durability as custom-cut slabs, offering resistance to scratches, heat, and stains.

- This makes it an ideal choice for high-traffic areas like kitchens where wear and tear are common.

Aesthetic Appeal:

- It is available in various colors and patterns, prefabricated granite can complement any kitchen or bathroom design while maintaining the luxurious look of natural stone.

Ease of Maintenance:

- Like all granite surfaces, prefabricated countertops require regular sealing to protect against stains but are otherwise easy to clean with mild soap and water.

Drawbacks of Prefabricated Granite

Limited Customization:

- One significant drawback of prefabricated granite is the limited selection of colors and styles compared to custom-cut options.

- Homeowners may find it challenging to match specific decor or design preferences.

Quality Concerns:

- Some prefabricated granite may be sourced from lower-quality materials or produced under less stringent quality controls overseas.

- This can lead to inconsistencies in thickness and appearance.

Installation Challenges:

- While installation is generally quicker, the need for precise measurements remains critical.

- Additional modifications might be necessary if the standard sizes do not fit perfectly into a unique space.

Seam Visibility:

- Due to size limitations, prefabricated countertops may require more seams than custom options, which can be visually unappealing if not executed correctly.

When to Choose Prefabricated Granite

Prefabricated granite is an excellent choice for various situations:

- Renovations: Homeowners looking for an affordable yet stylish option will find prefabricated granite appealing.

- Quick Turnaround Projects: For those who need fast installations—such as landlords or home flippers—prefabricated options offer speed without sacrificing quality.

- Standard Kitchen Designs: If your kitchen layout fits standard dimensions, prefabricated granite can provide a seamless look at a fraction of the cost.

Why is Prefabricated Granite Less Expensive?

- Prefabricated granite is produced and fabricated in large quantities which further eliminates the need for distributors or craftsmen to cut or shape it during installation.

- The convenience that the manufacturer gains by pre-cutting and finishing standard pieces in the factory is what ideally makes the huge(upto 45%) cost difference between prefabricated and custom-cut granite.

- For customers, prefabricated granite hints at a significantly faster turnaround time from order to delivery compared to other options such as custom granite.

- Prefabricated granite is well suited for commercial environments, such as counters in office buildings, sinks in restrooms, and cafeteria counters.

- One major reason for this is that the quality of prefabricated granite matches that of custom-cut slabs, and visually, they are often indistinguishable from one another.

- However, custom granite slabs are ideal for residential projects where homeowners desire designs tailored to their specific needs.

- Though, many kitchens and bathrooms can also benefit from prefabricated granite countertops without compromising on aesthetics.

- With careful planning, you can easily elevate your kitchen design at a lesser cost, you can leverage prefabricated granite to achieve a sophisticated look that rivals custom black granite slabs.

Are Prefab Granite Counters Made from Leftover or Cheap Remnants?

- Prefabricated granite is nothing close to “leftover” or “cheap”.

- Both prefabricated granite and custom granite slabs are composed of 100% genuine, high-quality A-grade granite – especially when sourced from reputed companies like Petros®.

- While custom granite slabs are cut to order, prefabricated granite benefits from its mass production.

- It is cut to standard sizes and then finished and polished in the factory before being offered for sale.

- Prefabricated granite is particularly well-suited for projects that require multiple pieces of the same size.

- The concept of prefabrication arose because granite countertops are significantly easier and quicker to install in their prefabricated form.

Are Prefab Granite Counters Suitable for Small Projects, or Can They be Used in Big Scale Installations too?

Due to the modular design of prefabricated granite and natural stone, they are ideal for use as premium surfaces in small as well as large-scale installations. Hotels often opt for prefabricated granite in hallways, elevators, and dining and reception areas.

Clients should ensure that there is sufficient stock in their chosen colors. It is often recommended to use patterns, especially for flooring and full-length wall finishes in showers and bathrooms. A tile pattern tool can be helpful for selecting colors, themes, and determining whether to use a single color of granite or multiple shades.

Special architectural projects that involve large installations often incorporate various colors and textures of granite to enhance striking structural features. While these projects typically opt for custom-cut slabs, it is entirely feasible to draw inspiration from such designs and adapt them for prefabricated materials.

At Petros® Stone, we offer extensive customization options for prefabricated granite countertops, allowing clients to select materials, colors, edge profiles, and sizes tailored to their specific project needs. This flexibility ensures that our countertops can seamlessly fit into various designs and applications, from residential kitchens to commercial spaces. Whether you prefer a sleek modern look or a more traditional style, our customizable options enable the creation of unique surfaces that enhance the aesthetic appeal and functionality of any environment.

The standard dimensions for prefabricated countertops are 112 inches x 26 inches x 0.78 inches (20mm). Although it may seem unusual to mix imperial and metric measurements, the thickness of the prefab granite is precisely 20 mm, or 2 cm.

Flat-finish countertops with a thickness of 2 cm feature a 1.5-inch laminated flat edge on one long side and both short sides.

For kitchen counters and bathroom vanities, backsplashes in matching granite are available at a height of 6 inches.

The popular kitchen island also comes in a standard prefabricated size of 108 inches x 42 inches x 0.78 inches (20mm), with a 1.5-inch laminated flat edge on all four sides as standard.

Will Prefabricated Granite Countertops Elevate my Home Value as Much as Slab Granite?

Installing new prefabricated granite countertops in your kitchen can indeed enhance your home’s value. The visual appeal of a well-designed kitchen countertop often plays a crucial role in attracting potential buyers. As previously mentioned, the differences between custom and prefabricated granite are minimal, so opting for the more affordable prefabricated option could be beneficial if you’re planning to sell your home.

Conclusion

Prefabricated granite countertops are an attractive option for homeowners seeking the luxurious beauty of natural stone without the time and cost associated with custom-cut slabs. While they offer significant advantages in terms of cost-effectiveness and installation speed, potential buyers should also consider limitations related to customization and quality.

Whether you opt prefabricated or traditional slab granite, both options provide unique benefits that enhance any living space while adding value to your home.

Frequently Asked Questions

1. What is prefabricated granite?

Prefabricated granite refers to granite countertops that are pre-cut and pre-finished in standard sizes. These countertops are designed to simplify installation and reduce costs compared to custom-made options. They often come with a bullnose edge and may include a matching backsplash for added aesthetic appeal and moisture protection.

2. Are prefabricated granite countertops made from real granite?

Yes, prefabricated granite countertops are made from 100% solid granite. There is a common misconception that they are made from leftover materials or lower-quality stone, but this is not true. The only difference between prefabricated and custom-cut granite is the manufacturing process and size.

3. Why are prefabricated granite countertops less expensive than custom slabs?

The lower cost of prefabricated granite is primarily due to mass production. These countertops are manufactured in bulk, which reduces labor costs up to 45% compared to custom-cut granite which demands custom cutting and finishing. Therefore prefab granite takes care of your pocket.

4. Can prefabricated granite be used in large installations?

Absolutely! Prefabricated granite is suitable for both small and large projects. Its modular nature allows it to be used effectively in commercial settings like hotels and restaurants, as well as residential applications. However, it’s essential to ensure that sufficient stock is available in the desired color for larger installations.

5. What customization options are available for prefabricated granite?

While prefabricated granite comes in standard sizes and finishes, some customization options do exist. Especially for large scale projects, when it is sourced directly from manufacturers of prefabricated countertops. At Petrosstone, we offer extensive customization options for prefabricated granite countertops, allowing clients to select materials, colors, edge profiles, and sizes tailored to their specific project needs. Homeowners can choose among different edge profiles, add backsplashes, or cut the slabs to fit specific spaces. However, these options are more restricted compared to fully custom countertops, which can be tailored to any size or design preference

Feel free to get in touch for a free consultation, quote, and get a detailed understanding from our experts here at Petros®. Visit https://petrosstone.com/ or call +91-8446360361 and WhatsApp

Hi!

I’m Ritupriya, and I bring together years of experience in architecture with a deep passion for writing. At Petros® Stone, I share my insights on natural stone, helping readers explore its role in design, durability, and timeless beauty.

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite