Engineered marble is an innovative synthetic stone that combines the elegance of natural marble with the durability and versatility of modern materials. It is crafted from a blend of marble dust, epoxy, and resins.

Engineered marble offers a stunning aesthetic that mimics the beauty of traditional marble while providing enhanced properties like better stain resistance higher scratch resistance characteristics.

Is Engineered Marble same as Faux Marble?

Its unique manufacturing process sets engineered marble apart from faux marble or porcelain. During the manufacturing of engineered marble, artificial marble blocks are first produced, which are then meticulously sawn into slabs and polished to achieve a refined finish.

This makes is a lot like natural marble – in the way that engineered marble slabs have induced pattern variations mimicing natural variations of marble.

- Is Engineered Marble same as Faux Marble?

- What is Engineered Marble Made of? (Composition)

- Why Engineered Marble is Preferred?

- Price of Engineered Marble

- Pros and Cons of Engineered Marble | Summary

- Advantages of Engineered Marble: Detailed

- Disadvantages of Engineered Marble: Detailed

- Engineered Marble vs Natural Marble

- Engineered Marble vs Quartz

- For what can Engineered Marble be used?

- How to Maintain Engineered Marble?

- Frequently Asked Questions (FAQs)

What is Engineered Marble Made of? (Composition)

- Engineered marble is primarily composed of marble stone particles along with specialized binding agents.

- The material contains 80-90% marble dust and chips, while the remaining 10-20% consists of polyester resins, pigments, and additional additives.

- The manufacturing process involves mixing these components, pouring them into precise molds, and subjecting the mixture to high pressure and heat to create solid and uniform blocks. These are then sawn into slabs, and the surface is polished.

Why Engineered Marble is Preferred?

Unlike natural marble, this synthetic material delivers consistent color, uniform and exotic patterns, and enhanced durability – all at a fraction of the cost of natural marble, making it an increasingly popular choice for both residential and commercial design projects.

The material’s innovative composition allows manufacturers to create surfaces that closely mimic natural marble’s luxurious appearance and at the same time it overcomes many limitations of the traditional stone.

Price of Engineered Marble

The price of Engineered Marble depends on nthe quality. Here is the price range of the most popular Engineered Marble qualities:

- Grace C – Lowest price: $20.50-$24.60 per square meter

- Grade B/Standard : $26.56-$32.99 per square meter

- Grade A: $36.99-$39.99 per square meter

Factors that influence Engineered Marble Price

- Thickness (10-25mm)

- Manufacturing quality

- Color and Design Options

- Supplier location/Country

Pros and Cons of Engineered Marble | Summary

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Durability and Resilience | – Resistant to stains and scratches | – Loses polish quickly |

| – Non-porous, prevents moisture absorption | – Not truly scratch-resistant | |

| – Long-lasting performance | – Difficult to repair once damaged | |

| Cost-Effectiveness | – Affordable compared to natural marble | – N/A |

| – Low maintenance costs | ||

| – Excellent value for investment | ||

| Design Flexibility | – Wide range of colors and patterns | – Limited finish options |

| – Uniform appearance | – Primarily glossy finishes | |

| – Customizable options | – Color pigments fade quickly | |

| Low Maintenance | – Easy to clean | – N/A |

| – Minimal upkeep | ||

| – Resistant to bacterial growth | ||

| – Hypoallergenic | ||

| Versatile Applications | – Suitable for countertops, vanities, flooring, wall cladding, decorative elements | – N/A |

| Eco-Friendly Manufacturing | – Utilizes recycled materials | – N/A |

| – Reduces quarrying demands | ||

| – Sustainable alternative | ||

| Stain Vulnerability | – N/A | – Easily stained by hard water and acidic liquids |

| – Stains are hard to remove | ||

| Temperature Sensitivity | – N/A | – Not heat resistant |

| – Prone to cracking under temperature fluctuations | ||

| Surface Degradation | – N/A | – Gel coating cracks over time |

| – Develops “crazing” | ||

| – Allows moisture penetration | ||

| Design Restrictions | – N/A | – Cannot achieve luxurious textured looks |

Advantages of Engineered Marble: Detailed

Engineered marble offers numerous benefits that make it an exceptional choice for modern design and construction projects. This innovative material combines aesthetic appeal with high performance. Following are the benefits of choosing Engineered Marble:

1. Durability and Resilience

- Highly resistant to stains and scratches

- Non-porous surface prevents moisture absorption

- More durable than natural marble

- Long-lasting performance in high-traffic areas.

2. Cost-Effectiveness

- More affordable than natural marble

- Lower maintenance expenses

- Provides excellent value for investment

- Budget-friendly alternative to traditional stone

3. Design Flexibility

- Available in wide range of colors and patterns

- Uniform appearance

- Customizable design options

- Consistent aesthetic across surfaces.

4. Low Maintenance

- Easy to clean

- Requires minimal upkeep

- Resistant to bacterial growth

- Hypoallergenic properties

5. Versatile Applications

Suitable for:

- Kitchen countertops

- Bathroom vanities

- Flooring

- Wall cladding

- Decorative elements

6. Eco-Friendly Manufacturing

- Utilizes recycled stone processing waste

- Reduces quarrying demands

- Sustainable alternative to natural stone

Disadvantages of Engineered Marble: Detailed

Despite its popularity, engineered marble comes with significant drawbacks that potential users should consider carefully before installation. The following are the various limitations of Engineered Marble:

1. Poor Durability

- Quickly loses its initial polish

- Not truly scratch-resistant

- Difficult to repair once damaged

- Surface shine deteriorates rapidly after installation

2. Stain Vulnerability

- Easily stained by hard water, toothpaste and acidic liquids

- Stains are challenging to remove completely

3. Temperature Sensitivity

- Not heat resistant

- Prone to cracking during temperature fluctuations

- Cannot withstand boiling water or extreme temperatures

- Unsuitable for high-heat environments

4. Surface Degradation

- Gel coating cracks over time

- Develops “crazing” – small surface cracks

- Allows moisture penetration

- Creates potential breeding ground for mildew and germs

5. Design Restrictions

- Limited finish options

- Primarily available in glossy finishes

- Cannot achieve luxurious textured looks

- Color pigments fade quickly.

Engineered Marble vs Natural Marble

| Engineered Marble | Natural Marble |

|---|---|

| Man-made material composed of 80-90% marble fragments Mixed with resins and pigmentsManufactured through controlled processes Consistent and uniform appearance | Formed through geological processes composed primarily of calcite created by extreme pressure and heat Unique, unrepeatable patterns traditionally associated with luxury |

| Aspect | Natural Marble | Engineered Marble |

|---|---|---|

| Appearance | Unique patterns | Consistent design |

| Maintenance | High | Low |

| Cost | Expensive | More affordable |

| Durability | Moderate | High |

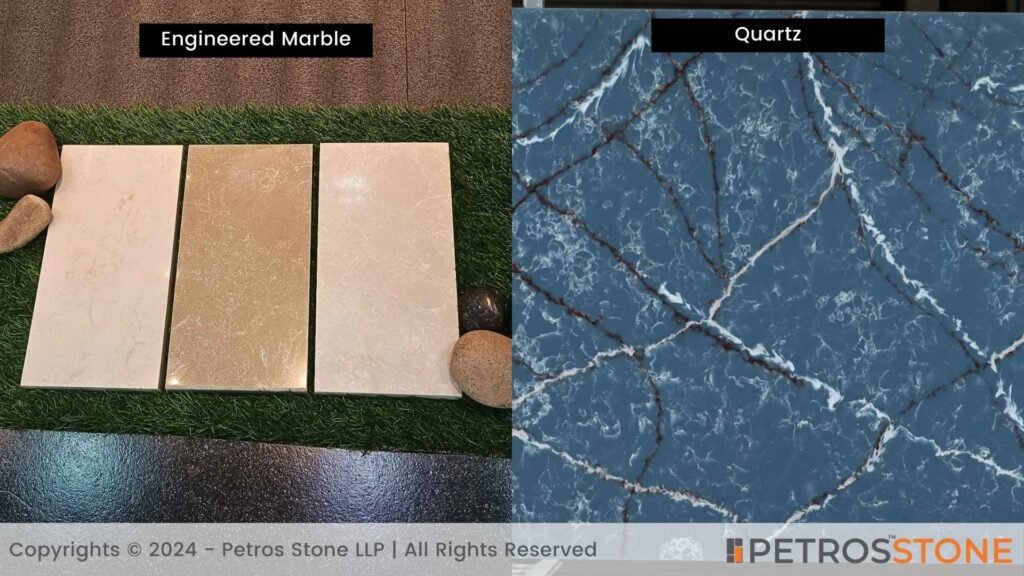

Engineered Marble vs Quartz

Engineered marble and quartz are both innovative synthetic stone materials that offer unique advantages for modern design and construction. Following charts their key differences and characteristics.

| Engineered Marble | Quartz |

|---|---|

| Composed of 80-90% marble fragments and dust Combines marble chips with polyester resins and pigments Creates a surface mimicking natural marble’s appearance | Manufactured using 93% natural quartz aggregates Blended with 7% resins and pigments Compressed and cured at high temperatures More consistent in pattern and color |

| Feature | Engineered Marble | Quartz |

|---|---|---|

| Durability | Moderate | Extremely high |

| Porosity | More porous | Non-porous |

| Stain Resistance | Limited | Excellent |

| Heat Resistance | Moderate | Lower |

Advantages of Engineered Marble

- More affordable

- Aesthetic variety

- Lightweight

- Easier installation

Advantages of Quartz

- Extremely durable

- Non-porous surface

- Low maintenance

- Consistent design options

- Better for high-traffic areas

Disadvantages of Quartz

- Can be damaged by excessive heat

- Potentially less natural appearance

- Higher initial cost

Engineered Marble vs Engineered Stone

Engineered marble and engineered stone represent two innovative synthetic surface materials, each offers unique characteristics and applications in modern design.

| Engineered Marble | Engineered Stone |

|---|---|

| Composed of 80-90% marble fragments Contains 10-20% polyester resins and pigments Manufactured by crushing marble, mixing with resins, and molding under high pressure | Created from ground natural stone particles Combines natural elements with artificial adhesives Uses polymer resins and pigments for binding Offers more uniform coloration and design options |

| Feature | Engineered Marble | Engineered Stone |

|---|---|---|

| Durability | Moderate | High |

| Stain Resistance | Good | Excellent |

| Maintenance | Low | Very Low |

| Customization | Limited | Extensive |

Engineered Marble vs Cultured Marble

Engineered marble and cultured marble are both synthetic alternatives to natural marble. Both of them offer unique characteristics and applications in modern design.

| Engineered Marble | Cultured Marble |

|---|---|

| Composed of 80-90% marble fragments Contains 10-20% polyester resins and pigments Manufactured by crushing marble, mixing with resins, and molding under high pressure | Contains approximately 75% marble dust Higher resin percentage More uniform and artificial look Typically manufactured with gel coating |

| Feature | Engineered Marble | Cultured Marble |

|---|---|---|

| Durability | Higher | Moderate |

| Stain Resistance | Excellent | Limited |

| Aesthetic Appeal | More Natural | More Uniform |

| Maintenance | Low | Moderate |

Installation Considerations – Engineered Marble vs Cultured Marble

- Engineered marble requires precise cutting and sealing

- Cultured marble can be molded into integrated designs

- Both offer versatile application in kitchens and bathrooms

For what can Engineered Marble be used?

Engineered marble offers exceptional versatility across multiple design and architectural applications, providing a durable and aesthetically pleasing alternative to natural stone.

Residential Applications

Kitchen Spaces

- Countertops

- Backsplashes

- Kitchen islands

- Highly resistant to stains and scratches

- Easy to maintain and clean

Bathroom Design

- Vanity tops

- Shower walls

- Flooring

- Moisture-resistant surfaces

- Hypoallergenic properties

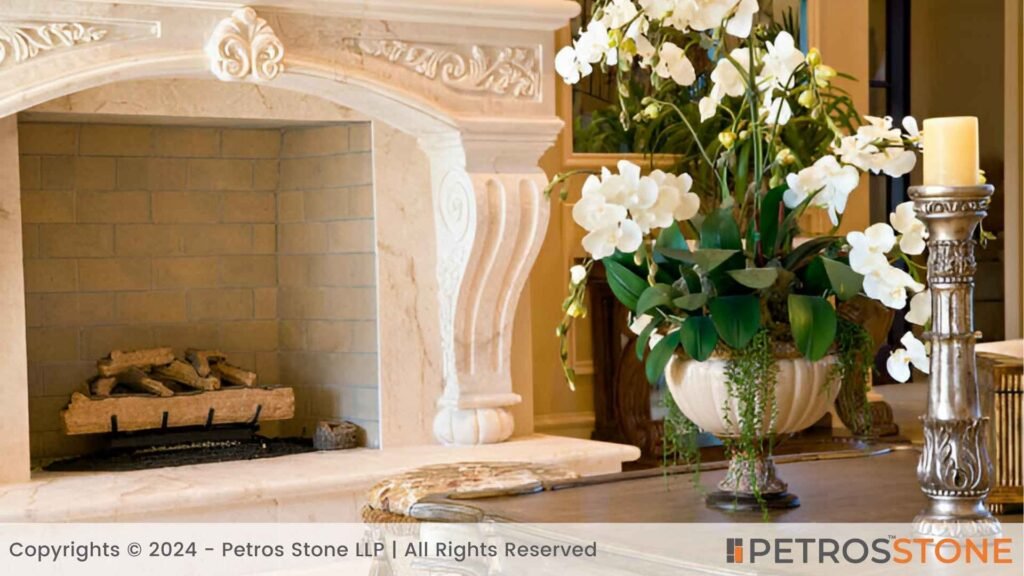

Commercial and Architectural Uses

- Interior Design

- Wall cladding

- Decorative paneling

- Lobby areas

- Fireplace surrounds

- Reception desk surfaces

Exterior Applications

- Facade treatments

- Outdoor landscaping elements

- Architectural accents

- Durable exterior surfaces

How to Maintain Engineered Marble?

Engineered marble requires consistent care to maintain its pristine appearance and long-lasting performance. By following a few simple maintenance techniques, you can keep your surfaces looking beautiful for years.

1. Daily Cleaning Routine

- Use a soft, lint-free microfiber cloth

- Remove dust and loose particles daily

- Dampen cloth with warm water

- Avoid excessive moisture

2. Cleaning Techniques with Mild Cleaning Solution

- Mix pH-balanced dish soap with warm water

- Use gentle, non-abrasive cloth

- Rinse thoroughly to remove soap residue

- Dry completely with clean cloth

3. Stain Removal for Engineered Marble

- Create baking soda paste for stubborn stains

- Apply gently to affected areas

- Let sit for few minutes

- Wipe clean without scrubbing

4. Preventive Measures

- Use coasters and placemats

- Avoid direct heat exposure

- Place protective pads under furniture

- Minimize direct contact with harsh chemicals

5. Professional Maintenance

- Inspect surface regularly

- Consider professional restoration if needed

- Reseal surface every 1-2 years

- Address chips or cracks promptly

Frequently Asked Questions (FAQs)

What is Engineered Marble?

Engineered marble is a man-made alternative to natural marble. It is created by combining crushed marble stone with resins, pigments, and additives to mimic natural marble’s appearance.

How is Engineered Marble made?

The manufacturing process involves the following steps:

- Crushing marble fragments

- Mixing with resin binders

- Pouring into molds

- Compressing under high pressure

- Curing and polishing the surface

What are the primary uses of engineered marble?

Engineered marble is suitable for:

- Kitchen countertops

- Bathroom vanities

- Flooring

- Wall cladding

- Decorative elements

How do I maintain Engineered Marble?

- Use mild detergent and warm water

- Clean with soft cloth

- Avoid abrasive cleaners

- Wipe spills promptly

- Periodic sealing typically not required

What are its key advantages?

- Consistent color and pattern

- Highly durable

- Stain and scratch-resistant

- More affordable than natural marble

Feel free to get in touch for a free consultation, quote, and get a detailed understanding from our experts here at Petros®. Visit https://petrosstone.com/ or call +91-8446360361 and WhatsApp

Hi!

I’m Ritupriya, and I bring together years of experience in architecture with a deep passion for writing. At Petros® Stone, I share my insights on natural stone, helping readers explore its role in design, durability, and timeless beauty.

Cot Ca Gold Granite

Black Wave Polished Granite

China White Granite

Pearl White Granite

Marquina Leather Granite

Red Lakha Granite