It is crucial to select proper materials to make steps and risers (vertical section of stairs). Such surfaces must be slip-resistant and fall-proof. From natural stone and engineered tiles to wood, metal, and composites, every option comes with unique strengths and limitations. By comparing their slip-resistance, maintenance needs, and costs, you can make a well-informed choice for both residential and commercial applications.

Price Range per sq. ft. of Best Materials for Steps and Risers

| Material | Approx. Cost (USD/sq ft) | Notes |

| Polished Granite | $10–25 | Higher for exotic colors or flamed finishes |

| Marble | $8–20 | Cheaper varieties at the lower end |

| Sandstone | $6–15 | Depends on the type and erosion resistance |

| Slate | $7–15 | Rustic options mid-range |

| Sintered Stone | $12–30 | Premium engineered option |

| Ceramic Anti-Skid Tile | $3–10 | Budget-friendly wide designs |

| Porcelain R11+ Tile | $5–15 | Depends on size/design |

| Hardwood (Teak, Oak) | $6–18 | Teak at high end, oak mid-range |

| Engineered Wood | $4–10 | Depends on veneer thickness |

| Wood-Look Tile | $5–12 | Combines tile durability and looks |

| Stainless Steel (diamond plate) | $20–40 | High due to metal and fabrication costs |

| Aluminium (with treatment) | $15–30 | Less if plain, more with coatings |

| Polished Concrete (DIY) | $3–8 | Contractor cost higher |

| Stamped Concrete | $5–12 | Depends on patterns, color seal |

| Precast Concrete Steps | $8–15 | Uniform and install-cost efficient |

| Glass with anti-skid coating | $25–50+ | Custom, luxury installations |

| WPC Decking | $6–15 | Per decking square foot |

| FRP Treads | $10–25 | Industrial-grade, varies by pattern |

In this article, we examine the top materials for steps and risers, with a focus on safety, durability, and aesthetics. Since stairs are among the most used parts of any building, the choice of materials directly impacts not just the look of the space but also its long-term performance and safety.

Role of Safety, Durability and Aesthetics

- Safety: The materials must be grippable even when worn or wet.

- Durability: Steps are high-traffic areas. Materials have to withstand wear as well as weather and cleaning.

- Aesthetics: Steps can be points of emphasis in interior or exterior locations. Materials are intended to enhance the style and design of architecture.

- Key Factors to Consider Before Choosing Step/Riser Materials

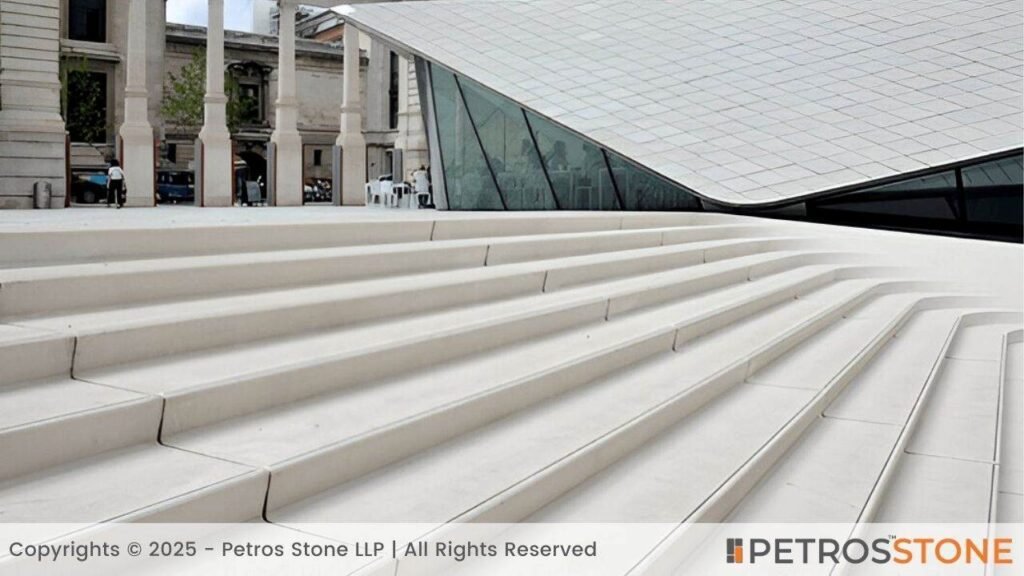

- Natural Stone Materials

- Granite Steps/Risers

- Marble Steps/Risers

- Sandstone Steps/Risers

- Slate Steps/Risers

- Engineered Stone & Tiles

- Sintered Stone – Safety, maintenance, and design variety

- Ceramic Tiles with Anti-Skid Finish – Pros, cons, and durability factors

- Porcelain Tiles for Steps/Risers – Pros, cons, and slip-resistance ratings

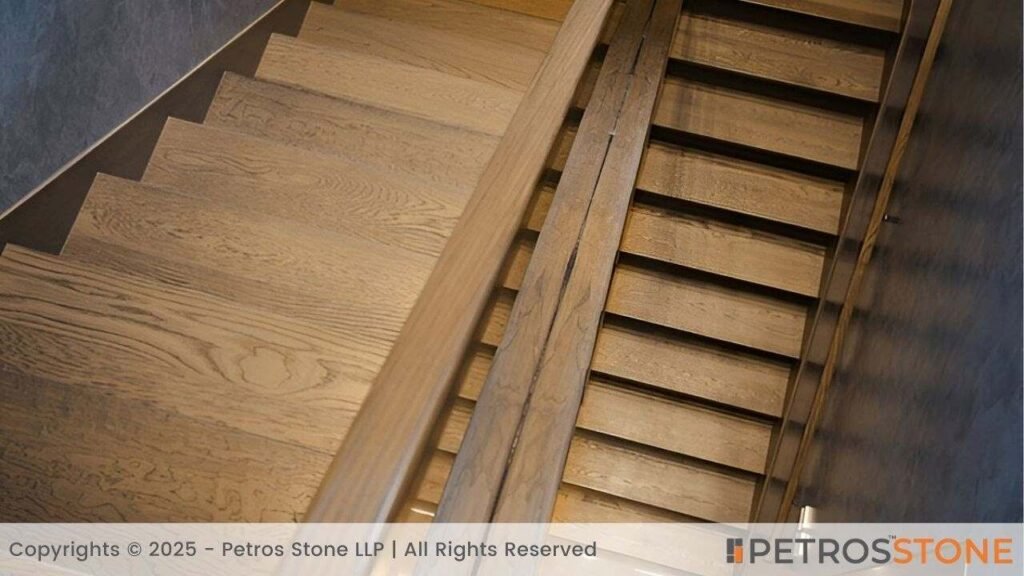

- Wood & Wood-Look Options

- Hardwood (Teak, Oak, etc.) – Safety, treatment, and aesthetic appeal

- Engineered Wood – Pros, cons, and maintenance tips

- Wood-Look Tiles – Safety features and weather durability

- Metal Options for Steps/Risers

- Stainless Steel Steps/Risers – Safety treatments, usage areas

- Aluminium Steps/Risers – Pros, cons, and anti-skid coatings

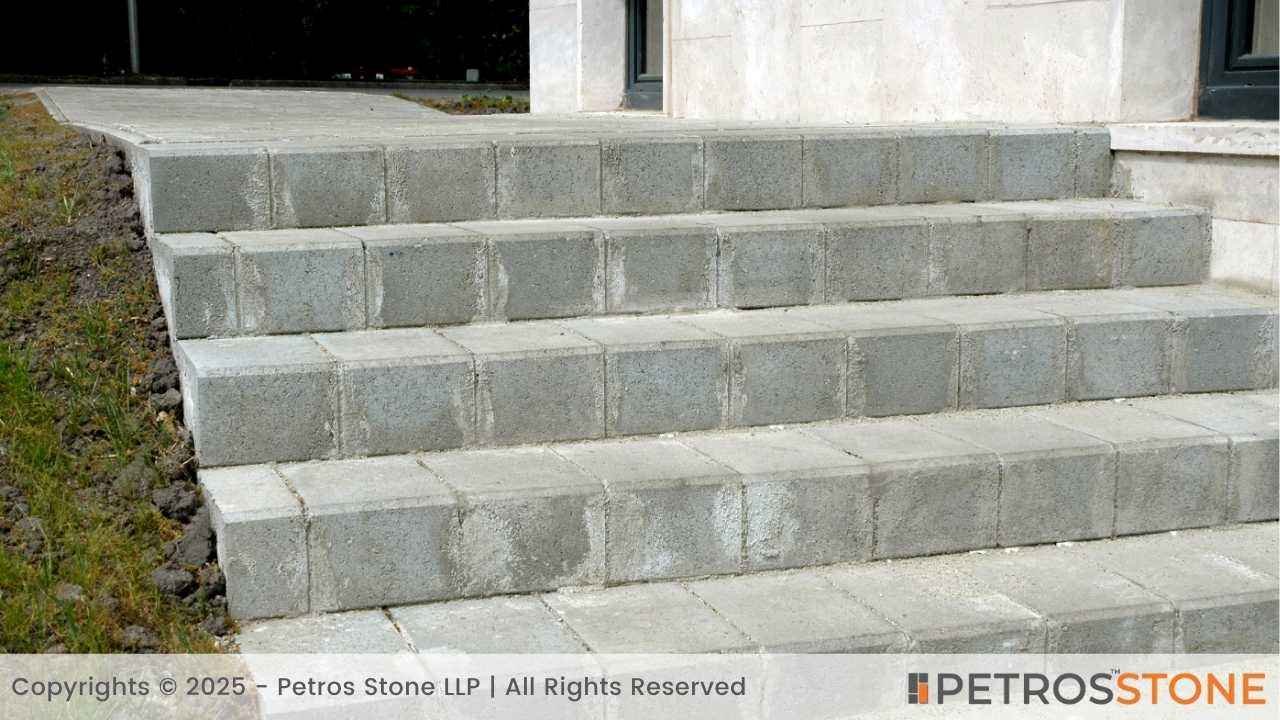

- Concrete & Cement-Based Options

- Polished Concrete – Pros, cons, and safety coatings

- Stamped/Patterned Concrete – Slip resistance and design flexibility

- Precast Concrete Steps – Durability and maintenance needs

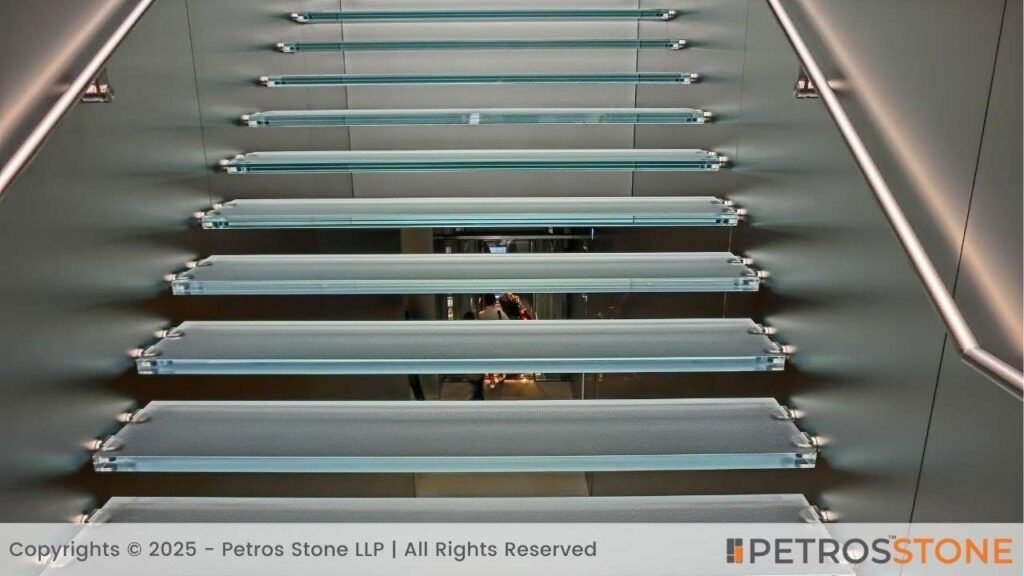

- Glass Steps with Anti-Skid Coating

- Composite Materials

- WPC (Wood-Plastic Composite) – Pros, cons, and safety aspects

- FRP (Fiberglass Reinforced Plastic) – Durability, slip-resistance, and cost

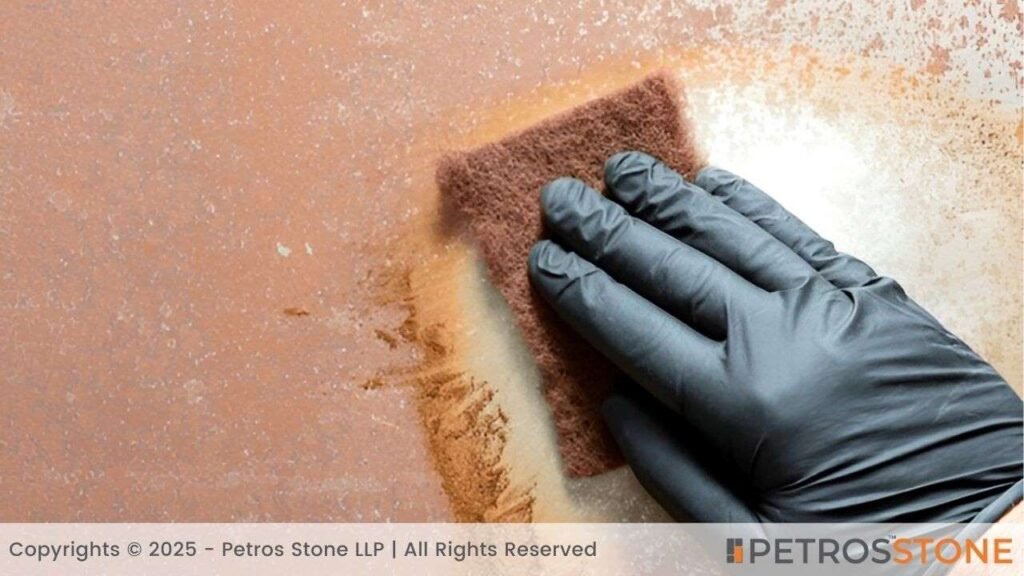

- Surface Treatments for Better Safety

- Choosing the Right Material for Different Settings

- Cost Comparison of Popular Step/Riser Materials

- Price Range per sq. ft. of Best Materials for Steps and Risers

- Maintenance Tips for Long-Lasting, Safe Steps

- Summary

- Key Takeaways

Key Factors to Consider Before Choosing Step/Riser Materials

Slip Resistance & Anti-Skid Properties

Materials with a high coefficient of friction, rough surface, or treads, in addition, should be sought. There are materials with natural gripping, and there are materials that need to be treated or attached.

Durability & Wear Resistance

The materials must be able to resist foot traffic, abrasion, UV (outdoors), and temperature changes. Feeble materials wear quickly and may prove hazardous.

Maintenance Requirements

Certain materials require regular cleaning or resealing or special attention. Minimal-care choices save years and money.

Aesthetic Appeal & Design Compatibility

Choosing materials has to follow your style of building, whether modern, rustic, or classic. Pay attention to color, texture, and finish.

Cost & Budget Considerations

To a greater extent, higher-end materials are more expensive to initially purchase but can save on maintenance or replacements. Weigh short-term expenditure against long-term valuation.

Indoor vs. Outdoor Applications

Steps are exposed to rain, frost, and direct sunlight- materials need to be waterproof, freeze-thaw proof, and fade resistant. The material within the house can be smoother, yet should have grip, particularly where children or old people live.

Natural Stone Materials

Overview Table: Natural Stone Options

| Material | Pros | Cons | Slip/Anti-Skid Features |

| Granite | Very durable, elegant, and wide colors | Expensive, heavy, cold | Natural texture, can be flamed/grit |

| Marble | Luxurious look, smooth finish | Slippery when polished, stains | Sandblasting, etching for grip |

| Sandstone | Warm, natural look, weather-resistant | Can wear/erode, less dense | Rough texture, cleft surface |

| Slate | Rustic look, good natural grip | Brittle edges, color variation | Naturally, slip-resistant layered |

Granite Steps/Risers

- Advantages: Granite is extremely tough. It offers sleek colors, designs that are hard-wearing.

- Disadvantages: It is heavy and expensive. Polished granite may be cold.

- Safety Features: To enhance traction, granite is either flamed (surface heated to create a non-slippery texture) or sandblasted.

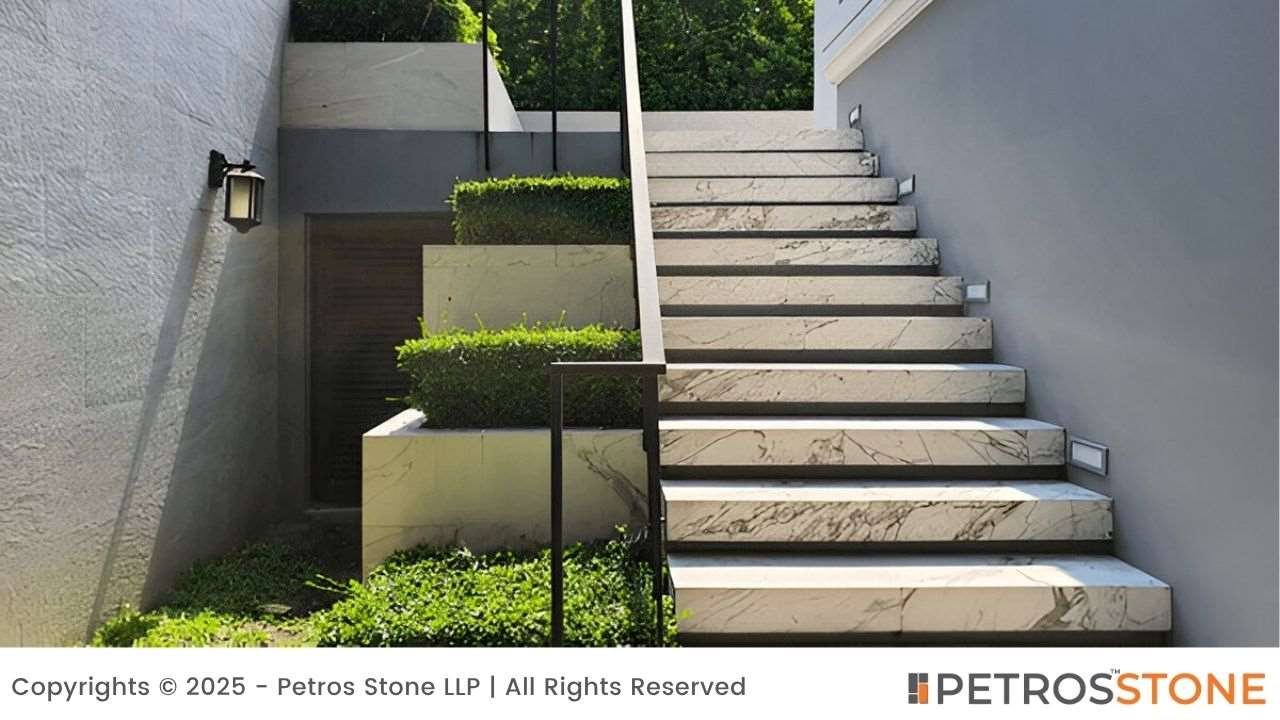

Marble Steps/Risers

- Advantages: Marble gives a high-end and classic look. Available in sold creamy tans to dark veins.

- Disadvantages: It gets stains easily, is porous, and polished surfaces are slippery.

- Anti-Skid Treatments: Surfaces can be treated to increase friction using methods such as sandblasting, chemical etching, or matte honing. Some grips or strips can be deployed on treads.

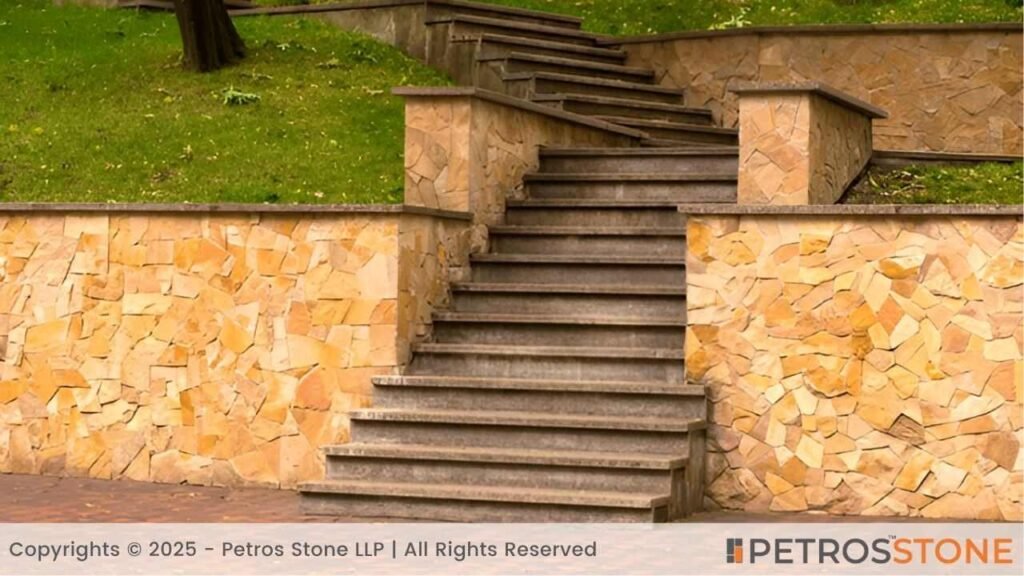

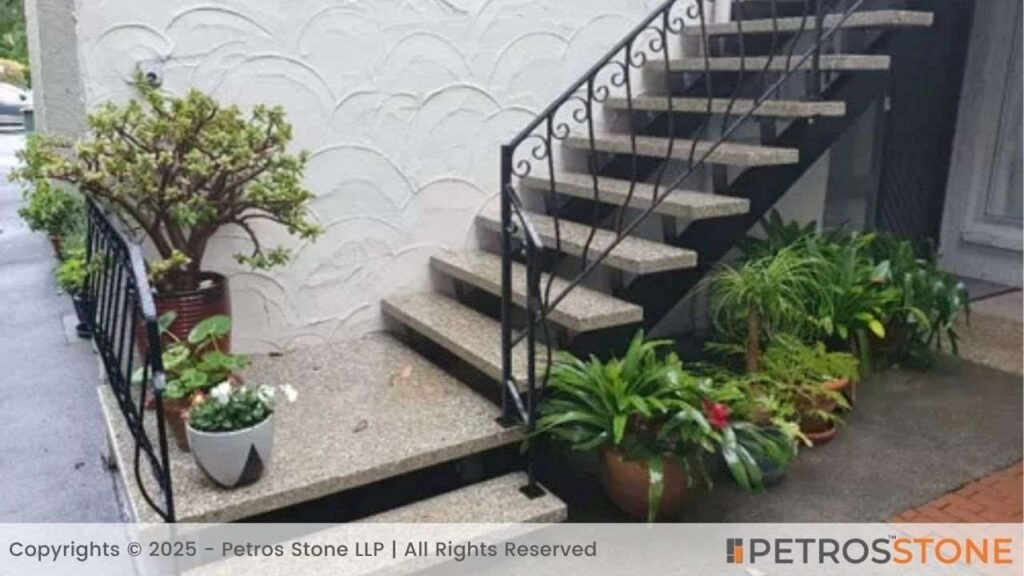

Sandstone Steps/Risers

- Advantages: Warm colors and natural finishes can be used in traditional or rustic style. Sandstone decays well.

- Disadvantages: Can be worn, splintered, or crumble under high usage or caustic metal cleaners.

- Weather Proof: The property of its texture, which is natural and rough, assists in good grip during wet conditions. It can be left outdoors too and survives well, and it can be sealed to preserve it.

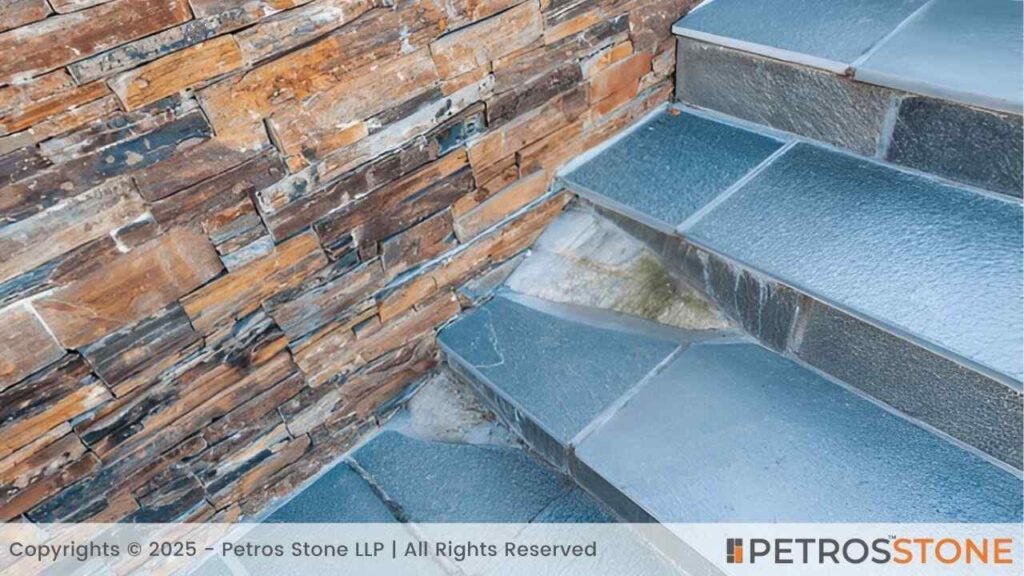

Slate Steps/Risers

- Advantages: Slate is a layered organism with a matte surface, which provides decent grip. It has an attractive earth-tone look.

- Disadvantages: Slate can chip around the edges and is thick in other areas.

- Slip Resistance: Naturally, it is among the more slip-resistant natural stones that are ideally suited to rustic or outdoor settings.

Engineered Stone & Tiles

The engineered stone and tile products are standardized and present a range of variety textures that can be controlled.

Overview Table: Engineered Stone & Tiles

| Material | Pros | Cons | Slip/Anti-Skid Features |

| Sintered Stone | Durable, UV-stable, many finishes | Costs vary, heavy | Textured finishes available |

| Ceramic Tiles (anti-skid) | Low cost, many designs | Less durable on edges, grout maintenance | Glazed anti-skid, textured surfaces |

| Porcelain Tiles | Very dense, low water absorption | Hard surfaces can be slippery if smooth | R11+, R12 slip-resistance ratings |

Sintered Stone – Safety, maintenance, and design variety

- Advantages: Processed under high temperature and pressure with natural minerals, long-woven, stainless, UV-resistant.

- Disadvantages: Bulky and expensive; installers should apply a strong sealant.

- Safety & Maintenance: Safety of many finishes is offered by providing them with grip through the honed, textured or sandblasted finishes. Cleanable.

Ceramic Tiles with Anti-Skid Finish – Pros, cons, and durability factors

- Advantages: Cheap, inexpensive, durable glaze, abundant range of design choices.

- Disadvantages: Edges are prone to chipping, and grout should be cleaned. Ordinary glazed tile is exceedingly slippery.

- Anti-Skid Features: Pick tiles that are labelled anti-skid or non-slip. They are usually grit-like or glazed textured to enhance traction.

Porcelain Tiles for Steps/Risers – Pros, cons, and slip-resistance ratings

- Advantages: extremely tough, minimal water uptake, does not freeze well–great outdoors.

- Disadvantages: Smooth, polished types are slippery. It can be bulky to put up.

- Slip Ratings: Porcelain tiles are rated R (Europe) or COF (Coefficient of Friction). Outdoor steps should only use R11 or R12 rated or COF greater than or equal to 0.6.

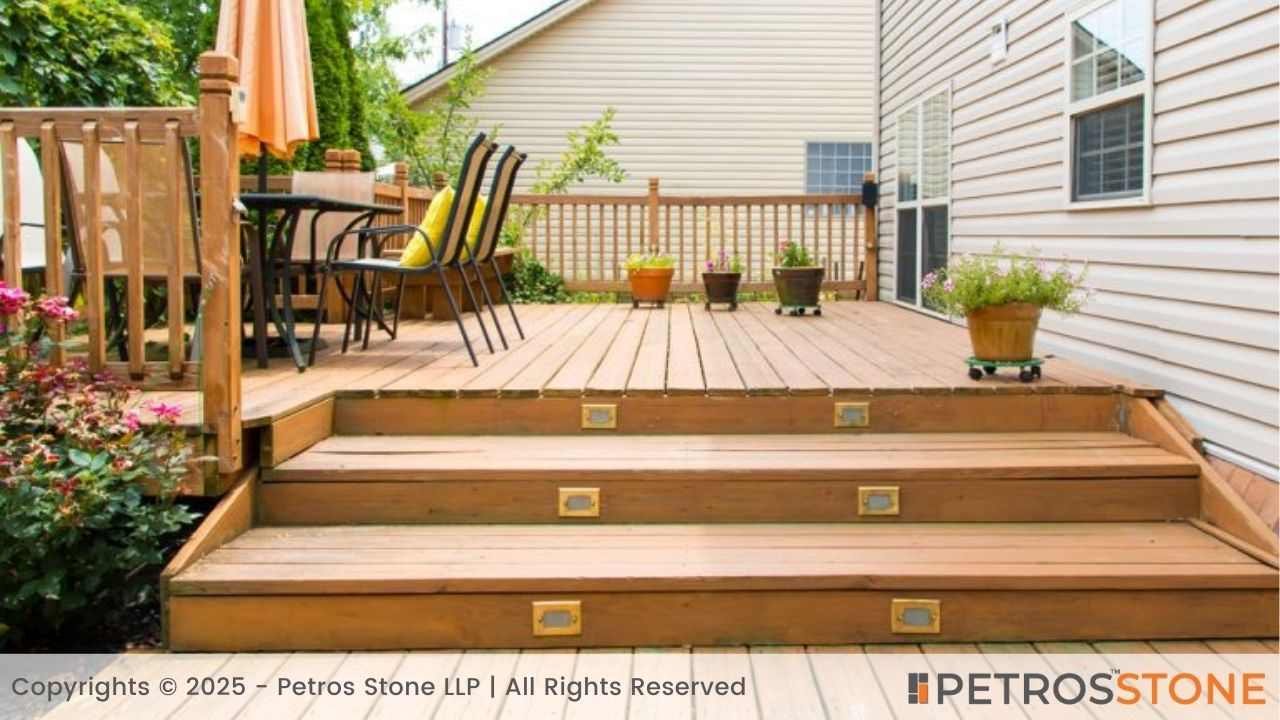

Wood & Wood-Look Options

Wood offers warmth with certain timeless beauty, yet safety and care must depend on the finish.

Overview Table: Wood & Wood-Look Options

| Material | Pros | Cons | Safety Features |

| Hardwood (Teak, Oak) | Warm, classic, strong | Prone to weathering or scratches | Non-slip finishes, anti-skid strips |

| Engineered Wood | Stable, cost-effective | The surface may wear faster | Textured veneer, coatings |

| Wood-Look Tiles | Wood appearance, ceramic base | Cold/hard, grout joints | Textured surface, anti-skid glaze |

Hardwood (Teak, Oak, etc.) – Safety, treatment, and aesthetic appeal

- Advantages: Wooden organizational natural, beauty, and power. Teak is naturally oily and decay-resistant.

- Disadvantages: Deteriorates in the open air, warps or splinters. Needs to be sealed and maintained.

- Safety Treatments: A non-slip stain or textured sealer can be employed. Grooved treads or anti-skid tape can be installed.

Engineered Wood – Pros, cons, and maintenance tips

- Advantages: Decreased warping, cheaper to manufacture, and a stratified design.

- Disadvantages: Veneer is subject to wear, and cheap types have reduced scratch resistance.

- Safety & Maintenance: Wash lightly, do not allow pooling of water. Use a non-slippery coat or fit stair strips.

Wood-Look Tiles – Safety features and weather durability

- Advantages: Does not fade, Natural-looking color of wood, Very seaworthy.

- Disadvantages: It is cold and hard to walk on, and it can accumulate dust in grout lines.

- Safety Features: A number of them are covered in non-slippery textures that simulate grain, providing proper grip. Select R-rated or COF-rated surfaces.

Metal Options for Steps/Risers

Suitable for industrial or modern stylings; safety necessitates deliberate textures.

Overview Table: Metal Options

| Material | Pros | Cons | Safety/Anti-Skid Features |

| Stainless Steel | Durable, sleek, hygienic | Slippery when wet, expensive | Diamond plate, perforations, coatings |

| Aluminum | Lightweight, corrosion-resistant | Softer, dents easily | Anti-skid coatings, abrasive strips |

Stainless Steel Steps/Risers – Safety treatments, usage areas

- Advantages: Sturdy, hard-wearing, stylish appearance, cleanable- excellent in institutions or heavy usage.

- Disadvantages: Slippery surface, slipping in wet cases.

- Safety Treatments: Diamond-plates pattern or perforated systems. Deposit on abrasive coating or grit. Commercial, marine or industrial use is popular.

Aluminium Steps/Risers – Pros, cons, and anti-skid coatings

- Advantages: They are light in weight, corrosion resistant, and ideal based on temporary or moveable stair units.

- Disadvantages: Less metallic; gets scratched or dented.

- Safety Enhancement: Paint or apply anti-skid strips or grit. Embedded aggregate tread cover performs excellently.

Concrete & Cement-Based Options

Concrete is versatile and cost-effective, with many finish possibilities.

Overview Table: Concrete Options

| Type | Pros | Cons | Safety Features |

| Polished Concrete | Sleek, modern, durable | Slippery if uncoated | Anti-slip coatings, etching |

| Stamped/Patterned | Decorative, customizable | Wear can reduce the pattern | Broom finish, textured stamps |

| Precast Concrete Steps | Uniform, fast install, strong | Heavy, limited finish options | Non-slip treads, aggregate surfaces |

Polished Concrete – Pros, cons, and safety coatings

- Advantages: Neat contemporary appearance, little upkeep, permanent.

- Disadvantages: Smooth to the point of being slippery (untreated).

- Safety Coatings: Add anti-slip epoxy or grit-impregnated sealers or etch to provide friction.

Stamped/Patterned Concrete – Slip resistance and design flexibility

- Advantages: It imitates stone, brick, and wood textures but is cheaper. Brilliant on the decoration of the house or garden.

- Disadvantages: Weather-resistant surface detail fades. Must reseal.

- Safety: The grip should be achieved with broom finish or textured stamps. Use anti-slip sealers.

Precast Concrete Steps – Durability and maintenance needs

- Advantages: Fabricated in a controlled environment- consistent strength, rapid placement. Low maintenance.

- Disadvantages: Lots of weight, pre-determined molds.

- Safety Features: Rough aggregate finish on many, or anti-skid treads may be added.

Glass Steps with Anti-Skid Coating

Fancy and bold- ideal when style is the most important aspect, but safety cannot be neglected.

Pros, cons, and safety enhancements

- Advantages: Super-modern, light-transmitting, elegant.

- Disadvantages: Costly, more glare, very slippery when bare.

- Safety Enhancements: It should contain tempered or laminated glass having anti-skid coatings, frit patterns, embedded grits or raised dot patterns. Frequently used instead of lighting to create a dramatic effect.

Ideal applications and design considerations

Best applied in luxury interior projects, bespoke stair systems, or commercial places. Give good handrails, edge lines, and anti-slip top where applicable in parking lots, wet locations, and so forth.

Composite Materials

Composite steps combine the advantages of wood, plastic, or fiberglass, often with low maintenance and weather-resistance.

Overview Table: Composite Materials

| Material | Pros | Cons | Safety/Anti-Skid Features |

| WPC (Wood-Plastic Composite) | Low maintenance, rot-resistant | Can fade, warm in direct sun | Grooved texture, anti-slip coatings |

| FRP (Fiberglass Reinforced Plastic) | Lightweight, strong, weatherproof | Can be costly, limited design | Slip-resistant gritted finish available |

WPC (Wood-Plastic Composite) – Pros, cons, and safety aspects

- Advantages: It does not rot unlike wood, it is relatively insect- and moisture-resistant, and offers a natural appearance with durability.

- Disadvantages: Color loses over time since it lacks pigments; it can get hot in the sun.

- Safety: Lots of manufacturers are offering WPC, with grooves or kínished antibacterial slip-resistant surfaces. Institute anti-slippery paints or strips where there is a need.

FRP (Fiberglass Reinforced Plastic) – Durability, slip-resistance, and cost

- Advantages: Very good ratio between strength and weight, non-corrosive, and non-warping. Perfect industries, marine or outdoor applications.

- Disadvantages: More costly, the works of design are often restricted.

- Slip Resistance: Molded mostly with grit or a diamond pattern. Safety is common with non-skid additives.

Surface Treatments for Better Safety

In many cases, surface treatment increases the slip-resistance of any material.

Anti-Slip Coatings & Sealers

Coatings of clear or colored material made rough by the addition of grit or silica raise friction. It may be used to cover stone, concrete, tile, or wood. Subsequent application may be required because of surface wear.

Textured Finishes

Broom finishes are applied to concrete, flamed stone, stippled paint, or embossed patterns on metal/tiles- these provide texture to limit slippery surfaces.

Anti-Skid Strips & Treads

Some retrofit options that can be useful on existing stairs are adhesive strips or screw-down tread covers (which are usually rubber or aluminium). Simple to layer, removable, and highly efficient.

Choosing the Right Material for Different Settings

Residential Indoor Stairs

- Best choices: Natural stone treated with anti-slipperiness, textured finish of hardwood, wood-look tiles with a grip, or WPC.

- Add safety and warm interiors, low noise.

Residential Outdoor Stairs

- Best choices: Sandstone, granite (flamed), textured concrete, porcelain R11 +, WPC with grooves.

- Weather resistance provides traction on wet or frosty surfaces.

Commercial Spaces

- Best choices: Stainless steel diamond plate, sintered stone, porcelain R11+, FRP treads, anti-skid paints.

- Should be able to handle high traffic, easily maintained, and very safe.

Public Infrastructure (Parks, Stations, etc.)

- Best choices: FRP, precast concrete covered with grit, aluminium cut with non-slip coating, highly rated COF textured tiles, and stone in intensive grooves.

- At the forefront is safety; materials should withstand weather and vandalism, and daily use.

Cost Comparison of Popular Step/Riser Materials

The approximate cost outline is as follows. Differences by region, supplier, and quality will influence the price.

Price Range per sq. ft. of Best Materials for Steps and Risers

| Material | Approx. Cost (USD/sq ft) | Notes |

| Polished Granite | $10–25 | Higher for exotic colors or flamed finishes |

| Marble | $8–20 | Cheaper varieties at the lower end |

| Sandstone | $6–15 | Depends on the type and erosion resistance |

| Slate | $7–15 | Rustic options mid-range |

| Sintered Stone | $12–30 | Premium engineered option |

| Ceramic Anti-Skid Tile | $3–10 | Budget-friendly wide designs |

| Porcelain R11+ Tile | $5–15 | Depends on size/design |

| Hardwood (Teak, Oak) | $6–18 | Teak at high end, oak mid-range |

| Engineered Wood | $4–10 | Depends on veneer thickness |

| Wood-Look Tile | $5–12 | Combines tile durability and looks |

| Stainless Steel (diamond plate) | $20–40 | High due to metal and fabrication costs |

| Aluminium (with treatment) | $15–30 | Less if plain, more with coatings |

| Polished Concrete (DIY) | $3–8 | Contractor cost higher |

| Stamped Concrete | $5–12 | Depends on patterns, color seal |

| Precast Concrete Steps | $8–15 | Uniform and install-cost efficient |

| Glass with anti-skid coating | $25–50+ | Custom, luxury installations |

| WPC Decking | $6–15 | Per decking square foot |

| FRP Treads | $10–25 | Industrial-grade, varies by pattern |

Installation & Maintenance Cost Considerations

- Some materials (granite, sintered stone) require proficient labor and firm foundations.

- Coatings and strips increase the cost of maintenance budgets, lower compared to replacements.

- Ceramic or stamped concrete, which are cheaper at first, necessitate more frequent upkeep.

Maintenance Tips for Long-Lasting, Safe Steps

Cleaning Methods

- Stone (granite, marble, sandstone, slate): None, only pH-neutral cleaners. Rinse well.

- Tiles: wash grout in mild detergent; do not use slippery waxes.

- Wood/WPC: Dust off, clean with the cleaning products of the manufacturer, and do not leave standing water.

- Concrete & Metal: Sweep grit; light pressure wash textured finish.

Regular Inspections for Wear and Tear

- Watch out for dull finishes or frays.

- Chisel out divinite grout or open seams.

- Check the rock or tile chips; the chips might be tripping hazards.

- Look for corrosion on metal, fungus on timber or UV-planned decay on composites.

Re-coating and Safety Upgrades

- Resurface non-slippery coating up to every 2-5 years; replace with wear.

- Change tread strips when peeling or worn out.

- Wood or composite surfaces can be retextured by refinishing.

- Grout re-seal to maintain grip and resist staining.

Summary

Choosing the right material for steps and risers is essential for balancing safety, durability, cost, and aesthetics. Options range from natural stones like granite, marble, sandstone, and slate to engineered surfaces such as sintered stone, porcelain, and ceramic tiles, each offering different levels of slip-resistance and maintenance needs. Wood, metal, concrete, glass, and composites provide additional design and functional alternatives depending on the setting. Surface treatments like anti-skid coatings, textured finishes, and strips further enhance safety. Ultimately, the best choice depends on whether the application is indoor, outdoor, residential, or commercial, ensuring long-lasting, slip-resistant, and visually appealing stairs.

Key Takeaways

- Safety First: Always prioritize materials with anti-skid or textured finishes, especially for outdoor or high-traffic stairs.

- Durability Matters: Granite, porcelain, and sintered stone are long-lasting, while wood and composites need more maintenance.

- Design Flexibility: From luxurious marble to rustic sandstone, every material contributes differently to the style of a project.

- Cost vs. Longevity: Cheaper options like ceramic tiles or stamped concrete may need more upkeep, while premium materials last longer with less maintenance.

- Application-Specific Choices: The best material varies by setting—flamed granite outdoors, WPC for low-maintenance decks, or stainless steel in commercial spaces.

Feel free to get in touch for a free consultation, quote, and get a detailed understanding from our experts here at Petros®. Visit https://petrosstone.com/ or call +91-8446360361 and WhatsApp

Hello!

I’m Dr Mridali, a content writer with a background in dentistry and a passion for turning complex topics into clear, engaging stories. From healthcare to architecture, I create blogs that inform, educate, and connect with readers. With every piece, I aim to blend accuracy with creativity to make information truly valuable.

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite