Infrastructure

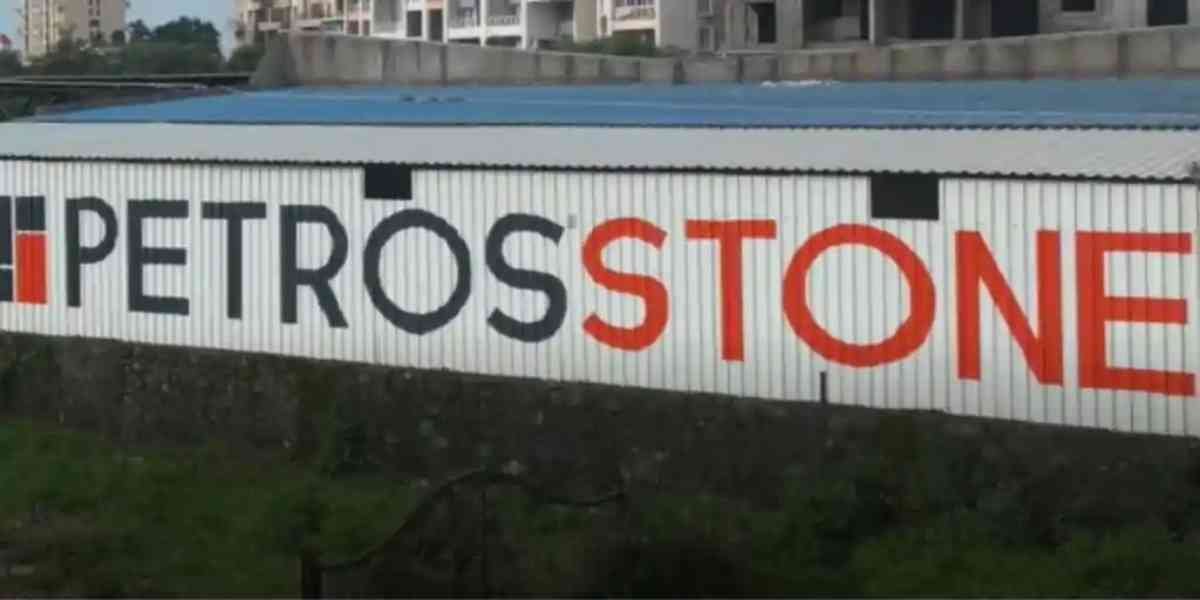

Petros® Manufacturing Unit

At Petros® Stone LLP, we pride ourselves on cutting-edge technology and precision engineering in – Granite, Marble, Quartz and Sintered Stone manufacturing. Our state-of-the-art facilities. located in Udaipur, Jambudiya and more (listed below) are equipped with world-class machinery, ensuring the highest standards in cutting, pressing, polishing, finishing, and fabrication of engineered and natural stone. With our 7-Step Quality Control (QC) measures, we guarantee consistency, durability, and premium aesthetics for every slab and tile we produce.

Petros® Manufacturing Unit

At Petros® Stone LLP, we pride ourselves on cutting-edge technology and precision engineering in – Granite, Marble, Quartz and Sintered Stone manufacturing. Our state-of-the-art facilities. located in Udaipur, Jambudiya and more (listed below) are equipped with world-class machinery, ensuring the highest standards in cutting, pressing, polishing, finishing, and fabrication of engineered and natural stone. With our 7-Step Quality Control (QC) measures, we guarantee consistency, durability, and premium aesthetics for every slab and tile we produce.

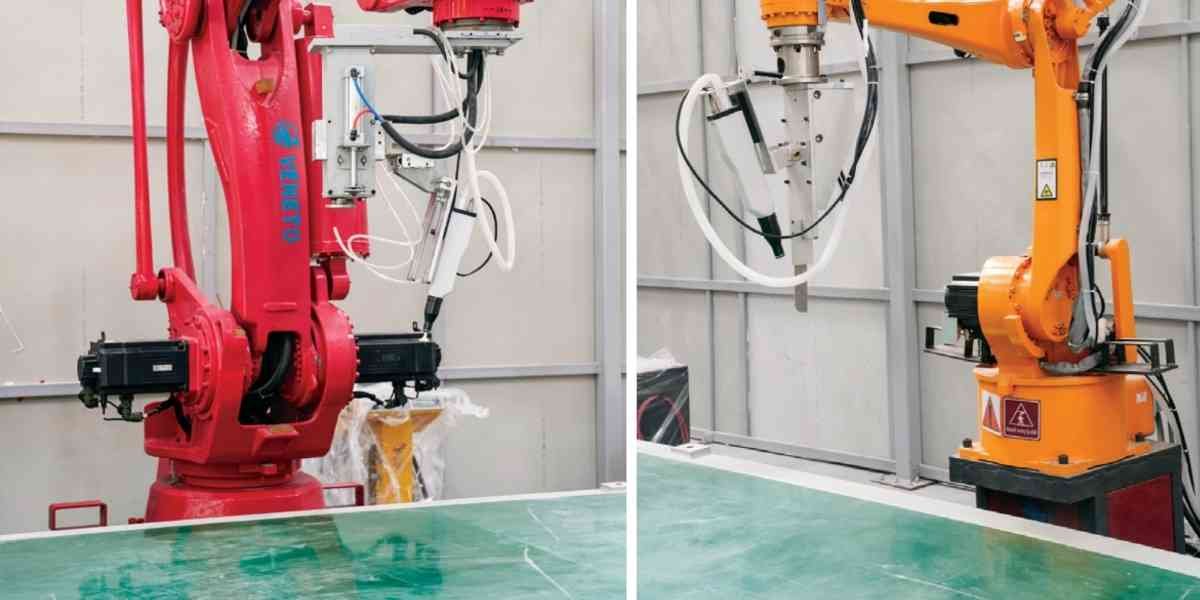

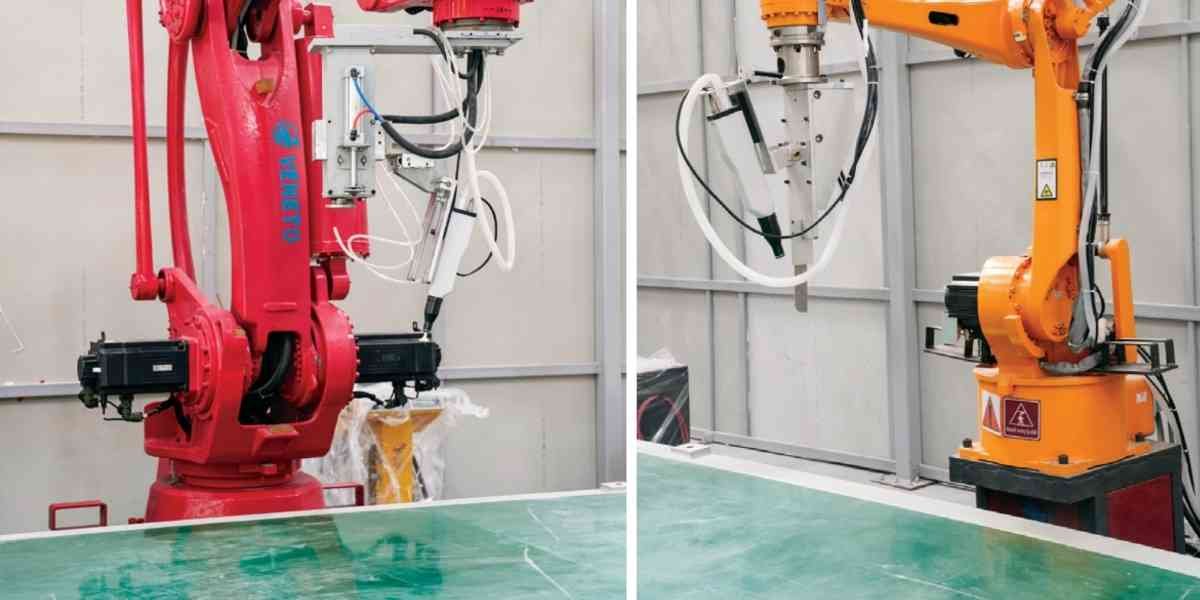

Our Machines

Manufacturing Process

- Udaipur

- Jambudiya

- Pune

- Budawada

- Vizag

- Karimnagar

- Madurai

- Navasheva

- Mundra/Kandla

- Chennai/Ennore

- Tuticorin

- Vizag

Granite & Marble Manufacturing

- Block Cutting: Large stone blocks are sliced into slabs using Multi-Wire Saw Machines.

- Resin Treatment: Enhances strength and minimizes surface imperfections.

- Polishing: Achieved with Automatic Multi-Head Polishing Machines for a smooth, glossy finish.

- Edge Cutting & Finishing: Ensures precise dimensions with Bridge Cutting Machines.

Quartz Stone Slab Manufacturing

- Mixing & Molding: Raw quartz is blended with resins and pigments.

- Vibro-Compression Under Vacuum: Strengthens slabs before curing.

- Curing & Hardening: Processed under controlled temperature conditions.

- Surface Finishing: Achieved through automated polishing for a flawless look.

Sandstone & Limestone Manufacturing

- Block Slicing & Dressing: Uses diamond wire saws.

- Flaming & Sandblasting: Creates textured, slip-resistant surfaces.

- Calibration & Thickness Control: Ensures uniformity for flooring and wall applications.

Sandstone & Limestone Manufacturing

- Block Slicing & Dressing: Uses diamond wire saws.

- Flaming & Sandblasting: Creates textured, slip-resistant surfaces.

- Calibration & Thickness Control: Ensures uniformity for flooring and wall applications.

Porcelain & Sintered Stone Manufacturing

- High-Pressure Sintering: Uses extreme heat to compact particles.

- Waterjet Cutting: For precise and customized designs.

- UV & Scratch Resistance Treatment: Enhances durability for high-traffic areas.

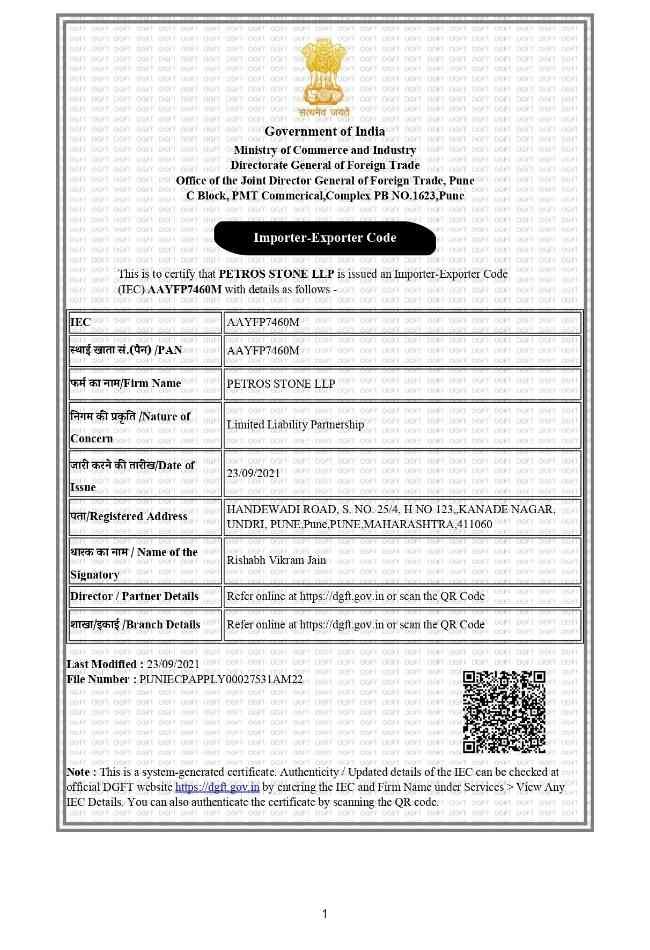

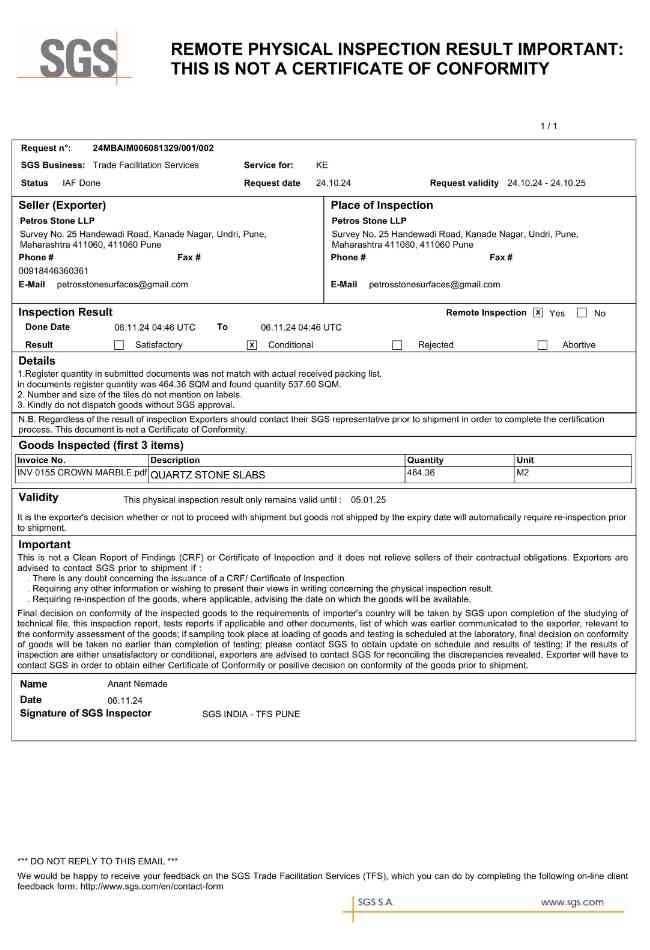

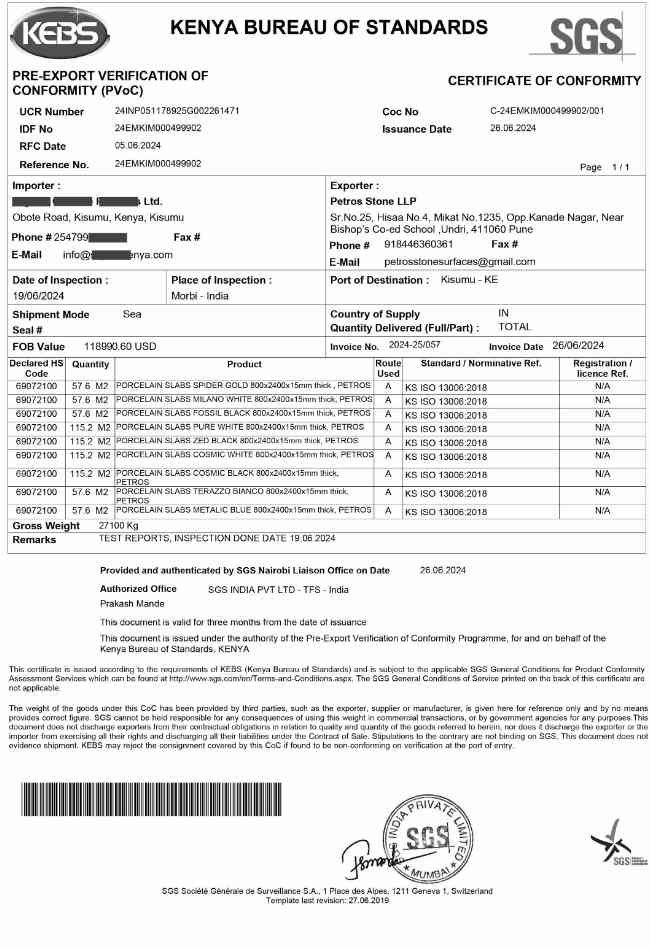

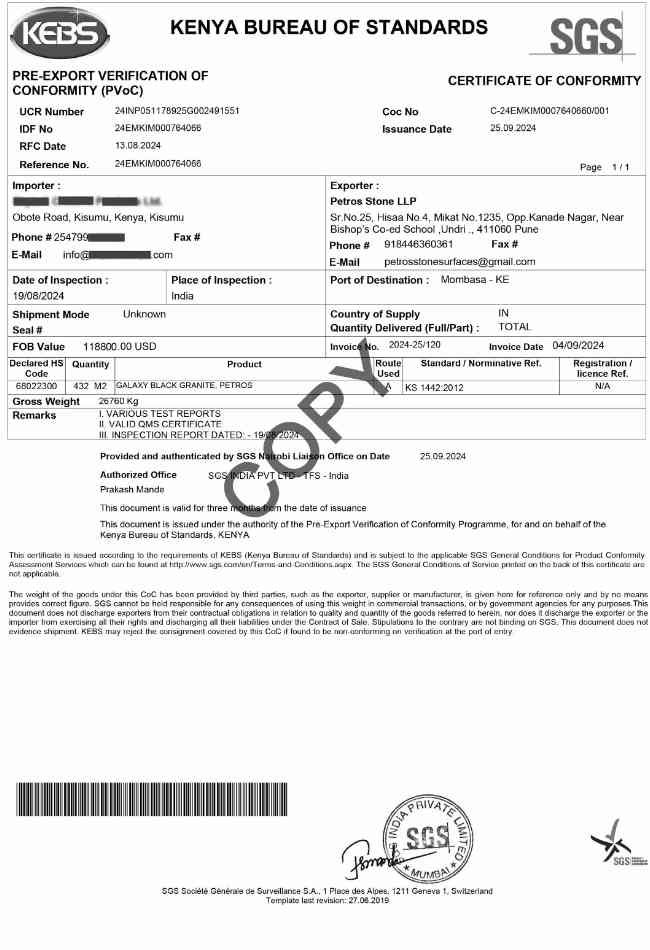

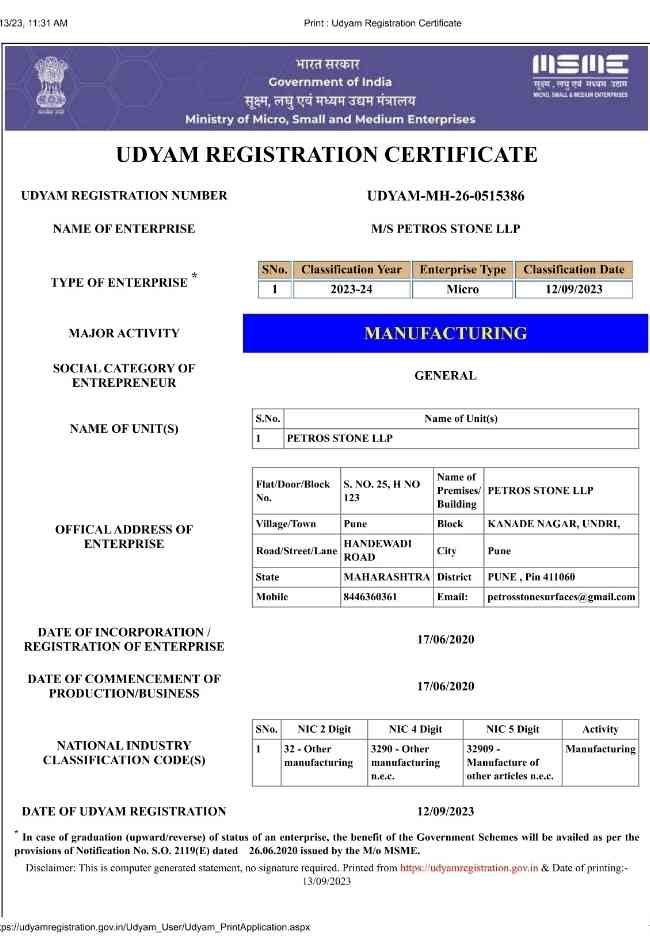

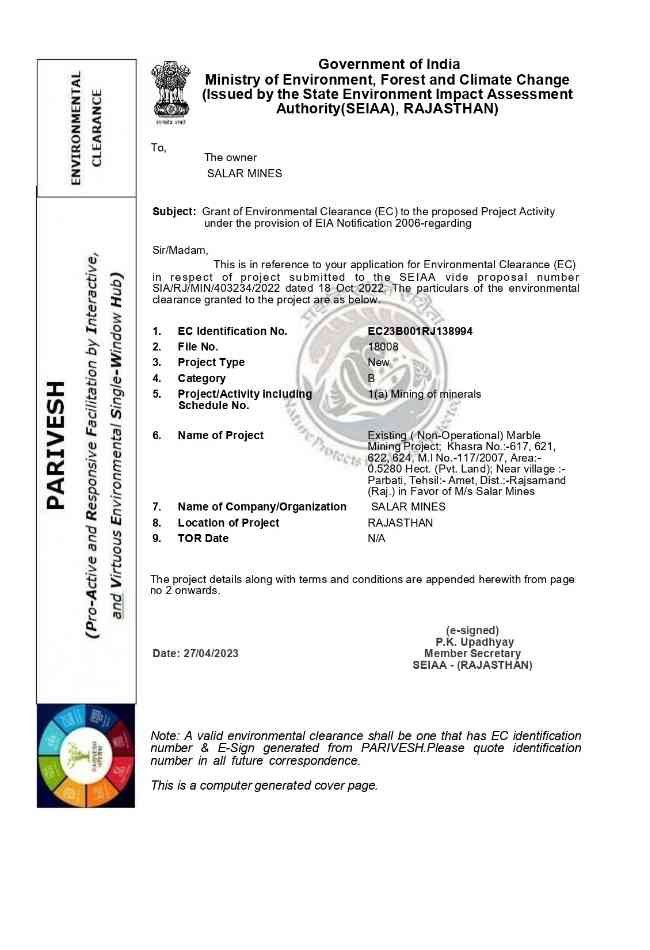

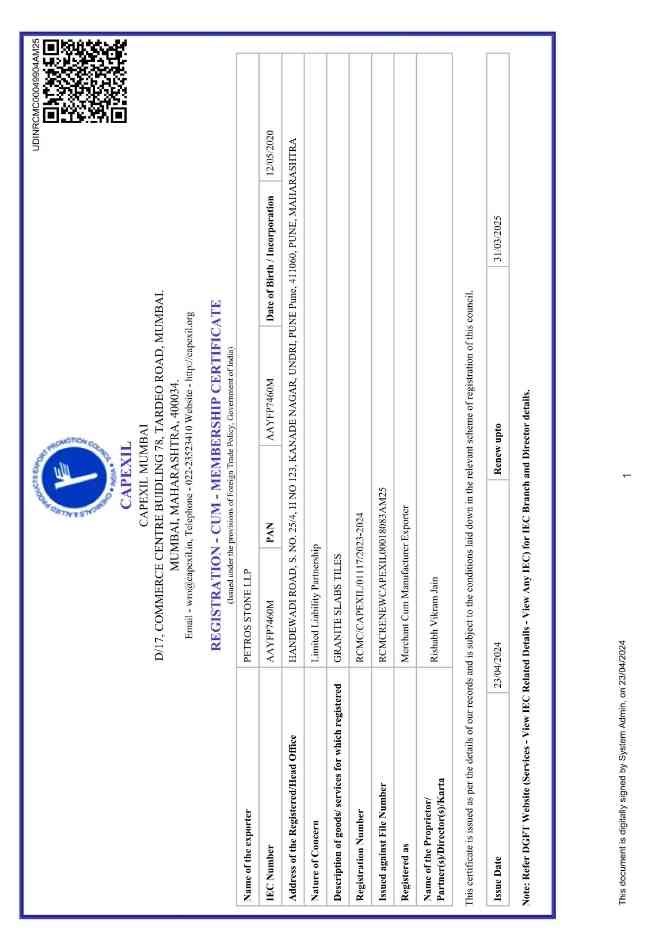

Certifications