Have you ever wondered what makes roads durable, industrial floors strong, or gives certain commercial spaces an ultra-modern look? Little stone chips are the answer!

These terribly useless-looking crushed rock pieces bear so much significance in various uses such as construction, manufacturing, and so many more. From their types and properties to their cost and alternatives, let’s talk about what these unsung realities of the building business are all about.

- What Are Stone Chips?

- How Are They Made?

- Applications of Stone Chips

- Production Process

- Types of Stone Chips

- Properties of Stone Chips

- Melting Point of Stone Chips

- Standard Sizes

- Uses of Stone Chips

- Some specific uses are as follows:

- Pros and Cons of Stone Chips in Different Applications

- Stone Chips for Garden

- Stone Chips for Driveway

- Stone Chips for Flooring

- Laboratory Testing and Certifications

- Alternative Options for Stone Chips

- Where To Buy Stone Chips?

- Conclusion

What Are Stone Chips?

Stone chips or stone chippings are small crushed stone pieces of little size or, in other words, crushed stone aggregates. These are used in construction for decoration, such as landscaping into gardens, or for industrial uses. Varieties of sizes and colors are available, depending on requirements.

How Are They Made?

The making of stone chips involves a fairly simple process:

- First, stones are quarried from natural rock formations.

- These stones are then crushed using machines like jaw crushers or impact crushers.

- The crushed pieces are screened to separate them into different sizes.

- Cleaning is sometimes undertaken to eradicate dust and impurities, after which they may be categorized by size, color, or other properties.

Applications of Stone Chips

Stone chips have many applications some of which are listed below:

Construction

Stone chips are the main ingredient in concrete and mortar to withstand all the weight they can throw onto it. Stone chips are extensively used for road bases too, providing a firm footing for highways, pavements, and bridges.

Industrial

The importance of stone chips to heavy industries is incalculable. Cement production is a major area where they are used as a raw material. Fine limestone chips act as a flux in arresting the melting temperature of silica in glass manufacturing. Also, they are used as filter media in water treatment plants to purify water by trapping impurities.

Agricultural

Stone chips are used by farmers as soil conditioners to enhance drainage in the nature of heavy clay soils. They find their use in farm management too — limestone chips are added to poultry feed as a calcium supplement for strengthening eggshells.

Some specific uses are as follows:

- For flooring-Used as a base for tile or stone floors or for decorative finishes.

- Commercial-Works well in parking lots and driveways, providing a stable base.

- Industrial-Being used in heavy-duty applications like railway ballast or foundries.

- Roads-In road bases and surfaces, ensuring stability.

Production Process

The manufacture of stone chips follows a series of processes in order that they conform to industrial set standards and specifications:

- Quarries and heavy machinery are usually used in stone extraction.

- Jaw, impact, or cone crushers are used to crush stones into smaller pieces.

- Screening separates crushed stone according to size – 5 mm, 10 mm, or 20 mm.

- Washing: Optional, but is done on some stone chips to wash them off dust and impurities that the quality is needed for specific uses.

- Sorting: In the end, they are sorted into size, color or more property-based to fit into various applications.

These processes render stone chips to appropriate uses from construction to decoration.

Types of Stone Chips

Stone chips are classified according to the rock-from which they are excavation and their application:

Marble Chips

Chips obtained from marble and are very suitable for decorative uses because they have an aesthetic value. They are available in colors such as white and pink.

Granite Chips

Chips that come from granite. They are most known for their durability and are commonly used in most constructions.

Limestone Chips

Obtained from limestone, this type of chip is mainly used in construction as well as for soil conditioning. It is enriched with calcium carbonate.

Basalt Chips

Basalt chips are made from basalt. Such chips are intended mainly for use in road construction, because of their strength and durability against wear.

Sandstone Chips

This type is obtained from sandstones and used for construction and decorative purposes. It has a wide variety of colours in it. They meet bespoke requirements with variations in colour and texture adding to their flexibility.

Properties of Stone Chips

In line with the stone from which it is sourced, the stone chips vary in their properties, thus affecting their suitability in their applications:

- Hardness: The rocks can be hard or soft regarding their durability parameters.

- Color: Applications in decoration are possible because these rocks grow white, black, and off-white, turning yellow, pink, green, or red inside.

- Size: Standard sizes for construction can also range extensively from fine dust to big lumps, such as 10 mm or 20 mm.

- Shape: With a few exceptions (e.g., round ones used for decorative purposes), stone is angular because it has been crushed.

Melting Point of Stone Chips

A melting point for stone chips as such cannot be given since they contain several minerals having different melting points, e.g. quartz in granite melts at about 1713°C, calcite in limestone decomposes at about 825°C.

According to general materials science references such variability means they will decompose under high heat rather than melting uniformly.

Chemical Composition of Crushed Stone

The chemical composition varies with type of stone by which the stone chips are made. Composition of different stone chips is listed as follows:

- Marble: Calcium carbonate predominantly (CaCO₃).

- Granite: Consists of quartz, feldspar and mica and features very high strength.

- Limestone: Again, mostly calcium carbonate; used in construction and agriculture.

- Basalt: Rich in magnesium and iron, containing pyroxene and plagioclase minerals; good for heavy-duty applications.

- Sandstone: Comprises sands grains, the binding between which can be silica and calcium carbonate.

We worked on the density because it is extremely important in concrete mixing and is given as follows:

- Marble – roughly 2.7 g/cm³

- Granite – 2.6 to 2.8 g/cm³

- Limestone – 2.5 to 2.7 g/cm³

- Basalt – 2.8-3.0 g/cm³

- Sandstone – 2.0-2.6 g/cm³

These values are used in calculating the stone weights and volumes for construction purposes.

Grade of Stone Chips

Stone chips are graded according to the size, and amongst the grades used are:

- 1/4 inch (6 mm)

- 1/2 inch (12 mm) 3/4 inch (19 mm)

- 1 inch (25 mm)

These grades guarantee the stones to meet specific project requirements for concrete and road construction.

Standard Sizes

Standard size of stone chips vary by its application:

- For concrete aggregates: Generally, 20 mm, 10 mm, 5 mm.

- Road construction: Larger sizes-50 mm, 25 mm.

- Decorative: Many sizes, from fine to coarse, depending on aesthetic requirement.

Uses of Stone Chips

Stone chips are used for many applications:

- Agriculture-for soil conditioning to improve drainage or litter in animal husbandry.

- Construction-as aggregates in concrete and mortar, for base layers of roads and drainage systems.

- Decoration-building gardens, walkways, aquariums, and terrariums, with bright-colored options for example white marble chips used for decoration.

- Industry-as raw materials for cement, glass, and filter media for water treatment.

Some specific uses are as follows:

- Flooring – Used as a base for tile or stone floors or for decorative finishes.

- Commercial – Works well in parking lots and driveways, providing a stable base.

- Industrial – Being used in heavy-duty applications like railway ballast or foundries.

- Roads – In road bases and surfaces, ensuring stability.

Pros and Cons of Stone Chips in Different Applications

A stone chip that is appropriate in one application may be totally unsuitable in another one:

Flooring

o Pros: Very durable, pleasing to the eye, good against moisture.

o Cons: If poorly finished, it is really uncomfortable to walk on. It also may call for maintenance.

Commercial (Parking Lots, Building Spaces, Public Space)

o Pros: Very cheap and durable. Can take heavy traffic.

o Cons: Regular grading is required and maintenance to prevent potholes.

Industrial

o Pros: Extremely high durability, withstands heavy loads and harsh environment.

o Cons: Some applications in industry may not be suitable for stone chips by virtue of their properties.

Roads & Road Works

Pros: To provide a stable base, offers good load distribution.

Cons: For high-speed roads, without proper surfacing, it may not be appropriate as the general construction practice suggests.

Stone Chips for Garden

Garden stone chips beautify the garden, stop weeds from growing, and add moisture to the soil. These should be pretty and should have smooth edges for safety, and of an appropriate size (usually 10-20 mm).

- White Marble Chips– INR 3000 to 7000 per ton Bright, elegant look; reflects light to highlight plants. It suits most minimalist or modern gardens. Can be very slippery when wet so keep off paths.

- River Rock Chips– INR 2000 to 4500 per ton Smooth, multicolored pebbles; typical water feature or zen garden pebbles (natural browns, grays); the polished finish adds a serene vibe.

- Colored Stone Chippings (Mixed) – INR 2,500 to INR 6,000 per ton dyed or natural reds, blues, or greens; the best for vibrant borders in gardens or areas for kids to play in. Ensure that the dye is non-toxic for the environmentally friendly use.

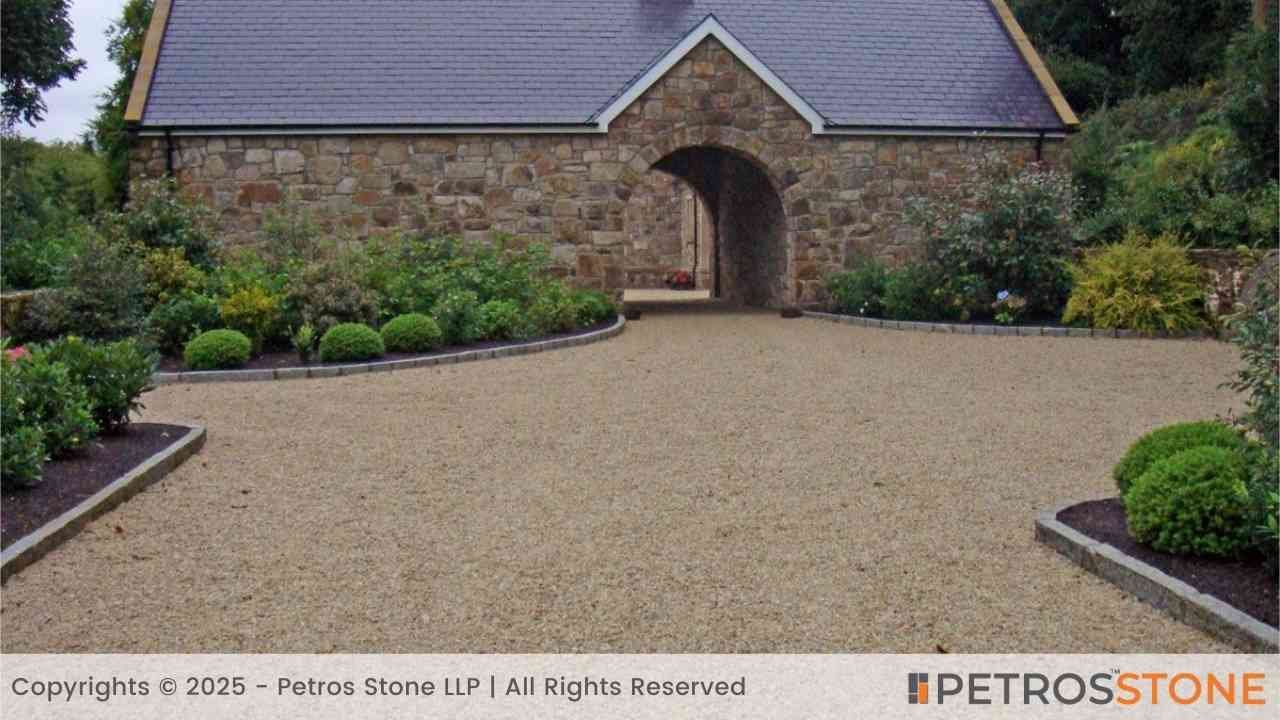

Stone Chips for Driveway

Driveway stone chips should be durable, angular to ensure stability, and sized (20-40 mm) for vehicle weight without shifting. Drainage and total cost also play a key role in it:

- Marble Chips INR 2,000 to INR 5,000 per ton Classic in terms of terrazzo, these are available both in white, black, and green. Polishes to a fine high shine for indoor floors or patios.

- Granite Chips-1800 to 4500 INR per ton Perfect for areas with high traffic such as lobbies. Very speckled color options. Non-slip when textured, making it ideal for outdoor flooring.

- Black Stone Chips (Pakur)-INR 1,500 to 3,500 per ton Very dense basalt chips; excellent for luxurious modern floors. Usually with white chips mixed in to give contrast in commercial spaces.

Stone Chips for Flooring

Flooring stone chips are 5-20 mm large and used in terrazzo, exposed aggregate, or decorative concrete. These should be hard, flat, visually striking, and good in bonding properties.

- Crushed Gravel Chips – INR 800 to INR 2,000 per ton

- This is an inexpensive blend of granite or limestone: interlocks very well for stability. Blends in neutral tones with most homes; requires topping up every now and then.

- Basalt Stone Chips – INR 1,200 to INR 3,000 per ton

- Dark, tough stone; withstands heavy traffic and weather. Angular shape ensures a firm base. Good for modern or industrial-style driveways.

- Granite Chips – INR 1,800 to INR 4,500 per ton

- Very strong and available in grays, reds, or blacks; does not get crushed under cars. Slightly expensive but very less maintenance.

What is the Price of Stone Chips Per Ton?

| S.No. | Stone Chip Type | Price Range (INR per ton) | Applications |

| 1 | Marble Chips | 2000 – 5000 | Decorative flooring, landscaping |

| 2 | Granite Chips | 1800 – 4500 | Construction, road making, aggregates |

| 3 | Limestone Chips | 1000 – 2500 | Cement production, base material applications |

| 4 | Basalt Stone Chips | 1200 – 3000 | Road construction, concrete mix |

| 5 | Black Stone Chips (Pakur) | 1500 – 3500 | Infrastructure works |

| 6 | Crushed Gravel Chips | 800 – 2000 | Driveways, path walks |

| 7 | Sandstone Chips | 1500 – 3500 | Buildings, landscaping |

| 8 | Quartzite Chips | 2500 – 6000 | Strong flooring, decorative applications |

| 9 | Dolomite Chips | 1200 – 3000 | Construction, soil conditioning |

| 10 | River Rock Chips | 2000 – 4500 | Landscaping, garden decoration (polished) |

| 11 | Blue Stone Chips | 2500 – 5500 | Ponds, gardens (limestone or sandstone variety) |

| 12 | Shale Chips | 1000 – 2500 | Lightweight concrete, landscaping (less durable) |

| 13 | Crushed Concrete Chips | 800 – 2000 | Road base, filling (recycled material) |

| 14 | White Marble Chips | 3000 – 7000 | High-end landscaping, premium driveways |

| 15 | Colored Stone Chips (Mixed) | 2500 – 6000 | Decorative purposes (dyed or natural multicolored chips) |

Laboratory Testing and Certifications

Stone chips are subjected to various tests for use in machinery and other industrial and construction applications:

• Grading and Size Analysis: Ensures uniformity as per the IS standards.

• Specific gravity and density: These are calculators used to measure weights per given volume, which are important in concrete mix design.

• Water Absorption: This test gives information about chips’ ability to absorb water and is considered a parameter in durability.

• Compressive Strength: This determines whether these can take the pressure; basically, they are used in structural solutions.

For any industrial use, such additional tests may include the chemical composition and purity, usually carried out in NABL-accredited labs.

Alternative Options for Stone Chips

Most of the time, alternatives to stone chips will depend on the application at hand. A few practical and viable substitutes from different industries are listed below:

1. Alternatives in Construction

For construction purposes, stone chips can be found used quite commonly in concrete mixes, in road bases, and in foundation layers. There are, however, several other alternatives that can be used interchangeably for the same functions:1. Alternatives in Construction

• Sand: This is a much rise resource used, with the option of being used with, or instead of, stone chips in concrete mixtures to obtain a much finer finish.

• Gravel: This larger-sized material compared to stone chips is usually found to be suited to making solid foundations and drainage zones.

• Recycled Concrete Aggregates (RCA): An eco-friendly and low-cost alternate material to reduce landfill waste. Obtained from crushed and processed concrete.

2. Decorative Alternatives

Stone chips confer a polished finish and enhanced beauty and ornamental value when used on garden pathways or for commercial aesthetics, while there are alternatives with their own merit and aesthetics:

• Pebbles: Smooth-rounded stone brought into a natural ornament finish for the gardens, pathways, and water features.

• Mulch: Organic materials, such as bark or coconut husk, are rustic-green but retain moisture for plant health.

• Wood Chips: The lightweight and bio-degradable nature of wood chips contribute to the warm, earthy views of garden beds or paths outside.

• Glass Chips: Tumbled and recycled for safety, these bring bright colour and shine into decorative spaces — a classic for modern landscaping designs. For instance, in a garden setting, organic mulches such as bark or wood chip benefit soil and aesthetics, while the glass chip boldly decorates in commercial outdoor designs.

3. Industrial Alternatives

Industries that rely on stone chips for heavy-duty processes or machinery should also resort to other specific materials:

• Slag, being a waste product of metal smelting, is highly durable and resistant to heat and can be used for base roads and industrial floors.

• Synthetic Aggregates: Manufactured products intended for achieving their specified consistency and performance with reference to the industrial needs specifications have been produced from recycled plastics, glass, or lightweight composites.

• Ceramic or Metal Fillers: In addition, ceramic or metal fillers may be preferred in precision manufacturing or at high temperatures because of their unique properties with regards to heat, weight, or wear resistance. Examples are composites or metal-based fillers used in machinery manufacturing instead of traditional stone chips in order to reduce weight or improve durability.

Where To Buy Stone Chips?

Petros Stone LLP

Why: Buy directly to the manufacturers, wholesalers, or exporters in India. It may offer a range from marble chips at INR 2,000–5,000/tonne, granite chips at INR 1,800–4,500/tonne, and river rock chips at INR 2,000–4,500/tonne.

Types Available: Colored aggregates, like white marble, black stone (Pakur), quartzite, limestone, etc., along with other aggregates meant for gardens and driveways and flooring.

How to Buy: Get in touch here

Tip: Ask for a photo for decorative chips to check whether the color and size conform to your needs.

Conclusion

Stone chips are versatile materials that find applications in construction, decoration, and industry. Their properties, costs, and testing requirements must be understood for choosing the right one for a specific need but there are certainly alternatives available for other scenarios. This thorough guide thus ensures a complete range of information at the reader’s disposal for decision making.

Feel free to get in touch for a free consultation, quote, and get a detailed understanding from our experts here at Petros®. Visit https://petrosstone.com/ or call +91-8446360361 and WhatsApp

Hi, I’m Khushbu,

With years of experience in the field of architecture, I’ve developed a deep appreciation for the impact of natural materials in design. At Petros® Stone, I write to share my perspective on how stone can modernize spaces with beauty, function, and timelessness.

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite