Sintered stone is an innovative countertop material – it is strong, durable, heat resistant, scratch resistance and excellently mimics the look of natural marble , granite, wood, or onyx. But are sintered stone countertops really the best?

Find out more about sintered stone and if a countertop made of it would be a good fit for your house.

- History of Sintered Stone

- What is Sintered Stone?

- What is Sintered Stone Made of?

- How Heavy are Sintered Stone Countertops?

- How Scratch and Stain Resistant are Sintered Stone Countertops?

- Are Sintered Stone Countertops Heat Resistant?

- Why Choose Sintered Stone?

- Sintered Stone vs. Quartz

- Sintered Stone vs. Porcelain

- Sintered Stone vs. Marble

- Benefits of Sintered Stone

- Drawbacks of Sintered Stone

- Uses and Applications for Sintered Stone

- Choosing the Right Material

- Is Sintered Stone Right for You?

History of Sintered Stone

European companies, including Lapitec and Dekton, pioneered sintered stone in the early 2000s. They created it to meet the need for tough, eco-conscious surfaces that outperform natural stone.

How Has Technology Grown

Sintered stone production has evolved rapidly. Initial designs were simple. Now, advanced methods craft detailed patterns and textures mimicking natural materials. Enhanced high-pressure techniques and extreme heat boost strength and allow larger slabs for bigger projects.

Current State of the Technology

Sintered stone leads as a top material, made mainly in Italy, Spain, and China. Cutting-edge printing creates lifelike designs. Green production cuts waste and emissions. Its durability and versatility suit countertops, cladding, and more in homes and businesses.

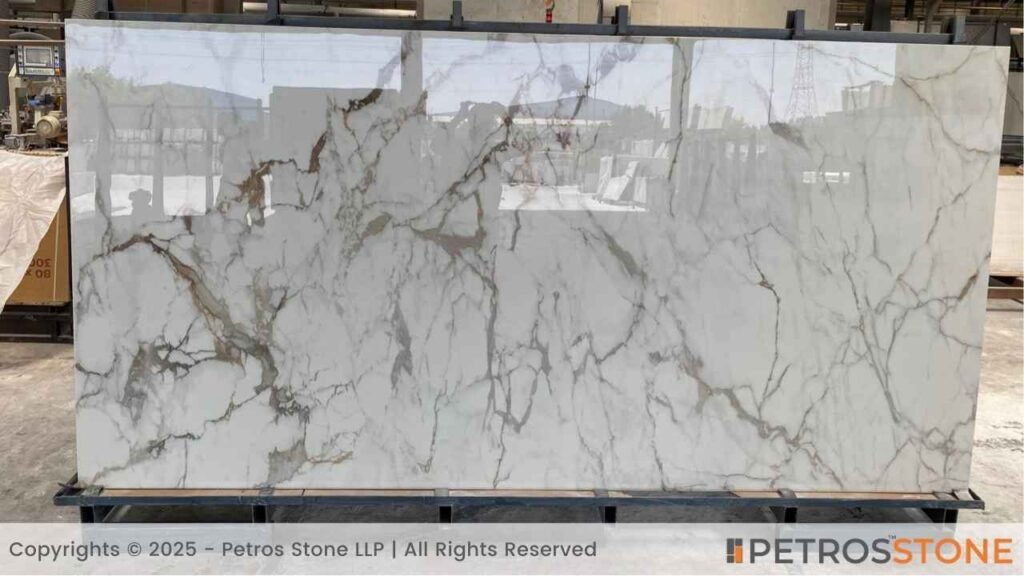

What is Sintered Stone?

Manufacturers craft sintered stone using intense heat and pressure on pure minerals. Unlike quartz, it uses no binders. The process fuses minerals, forming a solid, non-porous surface perfect for countertops.

What is Sintered Stone Made of?

Sintered stone blends granite, porcelain, quartz, and recycled glass. Workers grind and mix these materials finely. The result matches the beauty and strength of premium natural stones, blending style with practicality.

How Heavy are Sintered Stone Countertops?

Sintered stone’s weight depends on thickness. A 12mm slab weighs 30–35 lbs per square foot. A 20mm slab reaches up to 50 lbs per square foot. It matches granite or quartz in density but works well for countertops with proper support.

| Thickness (mm) | Weight per sq. ft. (kg) | Weight per sq. ft. (lbs) | Weight per sq. m. (kg) |

| 9 mm | 2.25 kg | 5.0 lbs | 24.2 kg |

| 12 mm | 3.0 kg | 6.6 lbs | 32.3 kg |

| 15 mm | 3.75 kg | 8.3 lbs | 40.4 kg |

| 18 mm | 4.5 kg | 9.9 lbs | 48.4 kg |

| 20 mm | 5.0 kg | 11.0 lbs | 53.8 kg |

How Scratch and Stain Resistant are Sintered Stone Countertops?

Sintered stone resists scratches and stains exceptionally. Its non-porous, dense surface handles knife cuts and spills like wine or coffee without marks. This makes it ideal for busy kitchens.

Are Sintered Stone Countertops Heat Resistant?

Sintered stone withstands heat up to 1200°C (2192°F). Place hot cookware directly on it without fear of cracks or discoloration. It outperforms many natural stones and laminates in heat resistance.

Why Choose Sintered Stone?

There are several reasons to go forward with sintered stone for your countertop. Using sintered stone has the following advantages –

- Extremely resilient.

- Suitable for Outdoor applications

- Heat Resistant

- Because sintered stones are waterproof, they won’t deteriorate when exposed to moisture.

- Non Toxic Surface

- Uniformity for large-scale projects involving matching slabs and stones.

- Sintered stones are simple to clean

- Sintered stones are non-porous, so sealing is not necessary to maintain their integrity.

- Sintered stones consists of large format slabs up to 10-1/2 feet by over 5-1/2 feet

- All sorts of surface finishes are available, from matte to high-gloss.

Manufacturing Process

Sintered stone countertops come from China, Italy, and Spain. They use raw minerals like zircon, hematite, and albite, plus recycled glass, quartz, and porcelain.

Materials are ground into fine powder. Powder is heated to over 1,000°C (1,832°F) until it forms a solid mass without melting.

High pressure shapes the sintered material into sheets.

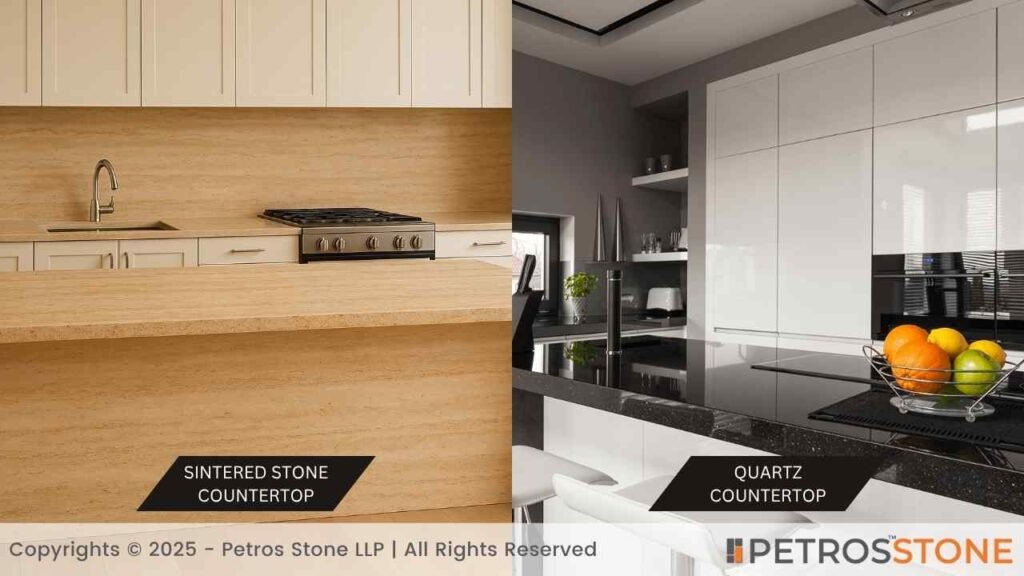

Sintered Stone vs. Quartz

- Sintered stone undergoes a distinct manufacturing process. Manufacturers compress and heat a mixture of natural minerals and pigments. This creates a denser, more resilient material compared to quartz. This then blends minerals with a binding resin and cures it in an oven.

- Sintered stone boasts a more organic appearance. It features color and pattern variations that mimic natural stone, while quartz maintains a uniform look with consistent color and patterns.

- Sintered stone offers similar durability to quartz. Both materials resist heat, stains, and scratches. This makes them low-maintenance countertop options. The choice depends on budget and aesthetic preferences.

| Aspect | Sintered Stone | Quartz |

| Manufacturing Process | Compress and heat minerals and pigments | Mix minerals with resin and cure in an oven |

| Appearance | Organic, natural stone-like variations | Uniform color and pattern |

| Durability | Highly durable, heat/stain/scratch-resistant | Highly durable, heat/stain/scratch-resistant |

Sintered Stone vs. Porcelain

- Sintered stone matches porcelain in water resistance. Both materials, being non-porous due to the sintering process, prevent liquid absorption, keeping surfaces clean and intact.

- Sintered stone rivals porcelain in scratch and chip resistance. Both outperform many natural stone alternatives, offering exceptional durability for countertops.

- Sintered stone outlasts many materials. With proper care, it can endure for decades, potentially up to 25 years, making it a long-term investment for your home.

| Aspect | Sintered Stone | Porcelain |

| Water Resistance | Non-porous, resists liquid absorption | Non-porous, resists liquid absorption |

| Scratch/Chip Resistance | Highly resistant, outperforms natural stone | Highly resistant, outperforms natural stone |

| Lifespan | Up to 25 years with proper care | Durable but lifespan varies with maintenance |

Sintered Stone vs. Marble

- Sintered stone surpasses marble in durability and maintenance. It resists stains and scratches better and requires less upkeep. Advanced technology allows it to mimic marble’s appearance.

- Sintered stone provides a cost-effective and eco-friendly alternative. It uses recyclable natural minerals without resins or harmful chemicals. It produces no carbon emissions during manufacturing, unlike marble, a non-renewable resource.

- Marble excels in aesthetic appeal. Its unique veinjing, color variations, and timeless elegance make it ideal for high-end surfaces. This is despite potential darkening and etching over time.

| Aspect | Sintered Stone | Marble |

| Durability/Maintenance | Harder, stain/scratch-resistant, low upkeep | Softer, prone to stains/etching, high upkeep |

| Eco-Friendliness | Recyclable, no carbon emissions | Recyclable but non-renewable, higher impact |

| Aesthetic Appeal | Mimics marble, modern look | Unique veining, timeless elegance |

Benefits of Sintered Stone

1. Exceptional Durability

Sintered stone comes from a process using intense heat, forming a strong material that resists damage. It handles the chaos of busy kitchens and bathrooms with ease. Its UV resistance keeps colors vibrant, preventing fading even after years of use.

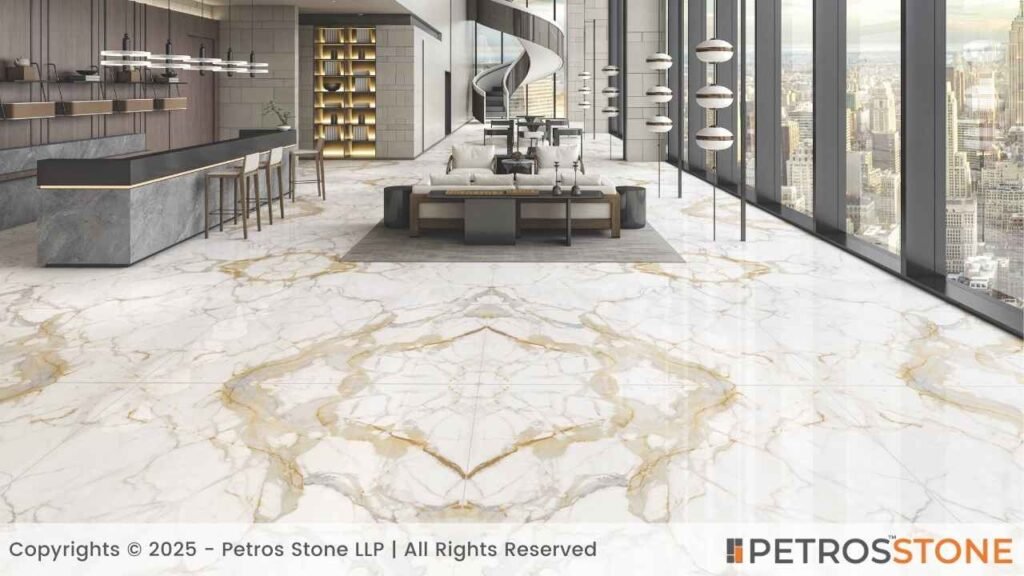

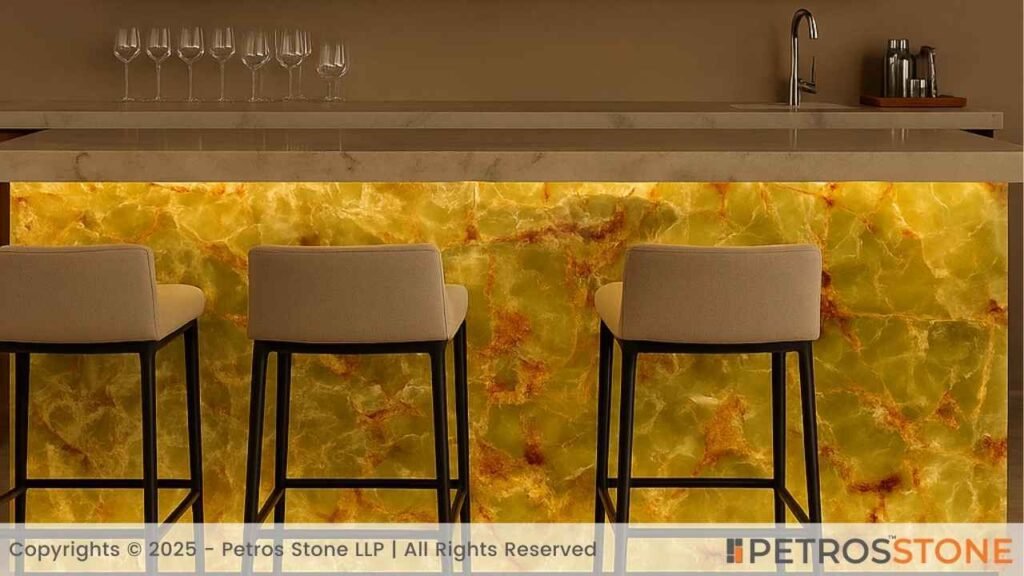

2. Versatile Design

Sintered stone offers a wide range of colors and patterns. Whether you love the sleek look of modern concrete or the timeless charm of marble, it adapts to your style. You can customize it to match any vision for your space.

3. Eco-Friendly Choice

Crafted from natural minerals, sintered stone avoids harmful chemicals. It’s a safe choice for your home and kind to the planet. The production process minimizes environmental impact, making it a responsible option.

4. Low Maintenance

The non-porous surface wipes clean with just soap and water. It resists mold and bacteria, keeping your space hygienic. You won’t need to seal it or spend time on deep cleaning, saving effort.

5. Heat Resistance

Sintered stone handles heat up to 1200°C without trouble. Set hot pots straight from the stove onto it—no cracks or discoloration. This makes it perfect for cooking areas where heat is constant.

6. Stain and Scratch Resistance

Spills like coffee or wine don’t soak in, thanks to its non-porous nature. The tough surface resists scratches and chips, even in high-traffic spots. It stays pristine with minimal care.

Drawbacks of Sintered Stone

Repair Challenges

Sintered stone is tough, but repairs are tricky. A chip or crack often means replacing the whole piece. Unlike natural stone, which can be patched or polished, this material doesn’t allow easy fixes.

Higher Cost

Sintered stone costs more than options like laminate. It’s often less pricey than high-end natural stones, but the upfront price can sting. Its long-lasting nature saves money over time, yet budget shoppers might hesitate.

Uses and Applications for Sintered Stone

Let’s move on to the exciting bit and talk about the kinds of things that can be made with sintered stone.Although some of these topics have previously been covered in earlier parts, we believe it would be beneficial to highlight some of the fantastic applications of this amazing stone. Nearly any application where natural stone can be utilized can benefit from the usage of sintered stone, including –

- Tabletops, islands, and kitchen counters

- Vanities and countertops in bathrooms, floors and Stairs

- Covers and wall cladding outdoor pathways, and patios near Fireplaces

- Wet rooms, swimming pools, and spas with tiling

For these applications, the sintered stones must be accurately measured and cut because they come in huge slabs. You might need to utilize several slabs to finish the project if you want to use the sintered stone to cover vast regions. Thankfully, consistency is another advantage of sintered stone, making it much simpler to match many slabs if necessary.

Choosing the Right Material

Factors to Consider

- Can it handle daily wear?

- Natural stone vibe or uniform look?

- Got time for sealing or polishing?

- What’s affordable now and later?

- Want a green option?

- Indoor, outdoor, or wet spaces?

Tips for Decision-Making

- Grab samples to see colors in your lighting.

- Talk to pros about installation and costs.

- Weigh upkeep needs against your lifestyle.

- Choose what fits your style and practical needs.

Material Recommendations

- Go for sintered stone if you want a tough, low-care countertop with a natural look, great for indoors or outdoors, and eco-friendly.

- Pick quartz if you love a sleek, consistent design and need a budget-friendly, durable indoor option.

- Choose porcelain if you need a light, waterproof material for bathrooms or pools with easy upkeep.

- Select marble if you crave elegant, unique patterns and can handle regular maintenance and possible stains.

Is Sintered Stone Right for You?

Sintered stone is gaining popularity for kitchen and bathroom countertops. It’s strong, versatile, and eco-friendly. While it may cost more upfront, its durability, low maintenance, and natural look outweigh the price compared to granite or quartz.

For a premium, long-lasting countertop, check out Petros® Stones’ sintered stone collection.

Feel free to get in touch for a free consultation, quote, and get a detailed understanding from our experts here at Petros®. Visit https://petrosstone.com/ or call +91-8446360361 and WhatsApp

Hi, I’m Shivangi,

With years of experience in the architecture and design space, I write to bridge the gap between material knowledge and practical application. At Petros® Stone, I create content that highlights the beauty, function, and impact of natural stones, helping homeowners and professionals make confident design decisions.

Explore my LinkedIn profile to learn more about my work!

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite