Quartz slabs are among the most widely imported materials from India, which is one of the largest producers of high-quality quartz slabs. Many of the world’s leading quartz companies source their quartz from India, making high-quality quartz more affordable in the country.

Price of quartz slabs depends on factors such as size, thickness, and, most importantly, the design. Here is the price of quartz slabs in India based on their size.

Size (mm) Category Thickness Price (INR/sqft) Price (USD/sqft) FOB Port 1600 x 3200 Jumbo 2 cm INR 250 – INR 550 USD 3 – USD 6.5 Mundra 1600 x 3200 Jumbo 3 cm INR 330 – INR 630 USD 4 – USD 7.5 Mundra 2000 x 3500 Super Jumbo 2 cm INR 300 – INR 600 USD 3.5 – USD 7 Mundra 2000 x 3500 Super Jumbo 3 cm INR 380 – INR 710 USD 4.5 – USD 8 Mundra

The typical price of quartz slabs in India ranges from INR 240 to INR 550 per square foot for 2cm slabs and INR 350 to INR 650 per square foot for 3cm slabs. Quartz slabs manufactured using advanced Italian technologies, such as Breton technology, tend to be more expensive compared to those produced using conventional methods.

Here is the price of Quartz depending the design:

| No. | Name of Quartz Slab | Images | Price | Click Here for the Exact Price | Contact Whatsapp |

| 1 | Sparkly Quartz Slab | INR 200-INR 300/sqft USD 2.75 – USD 3.5/sqft | Exact Price | Chat | |

| 2 | Plain Quartz Slab | INR 240-INR 340/sqft USD 3 – USD 4/sqft | Exact Price | Chat | |

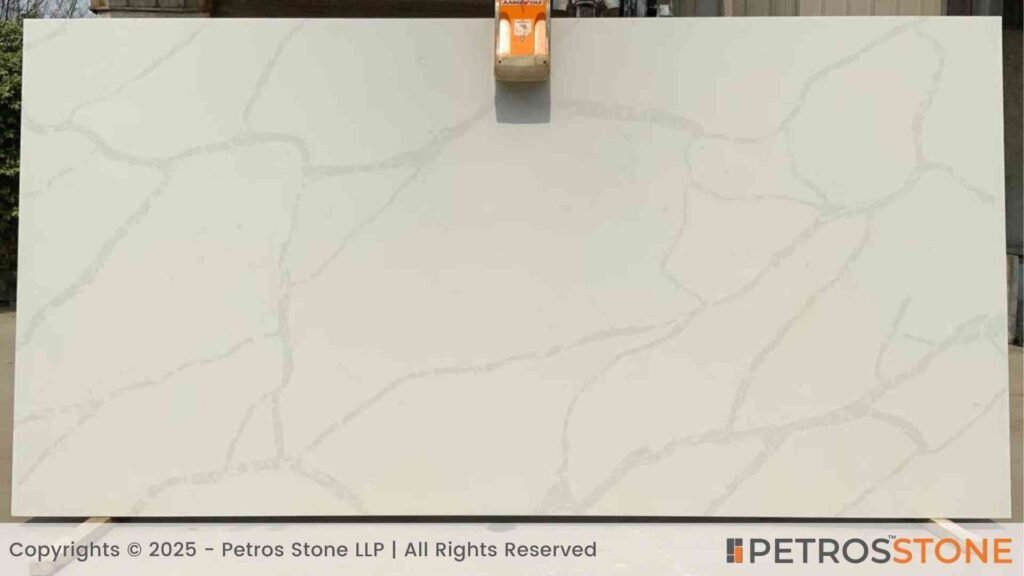

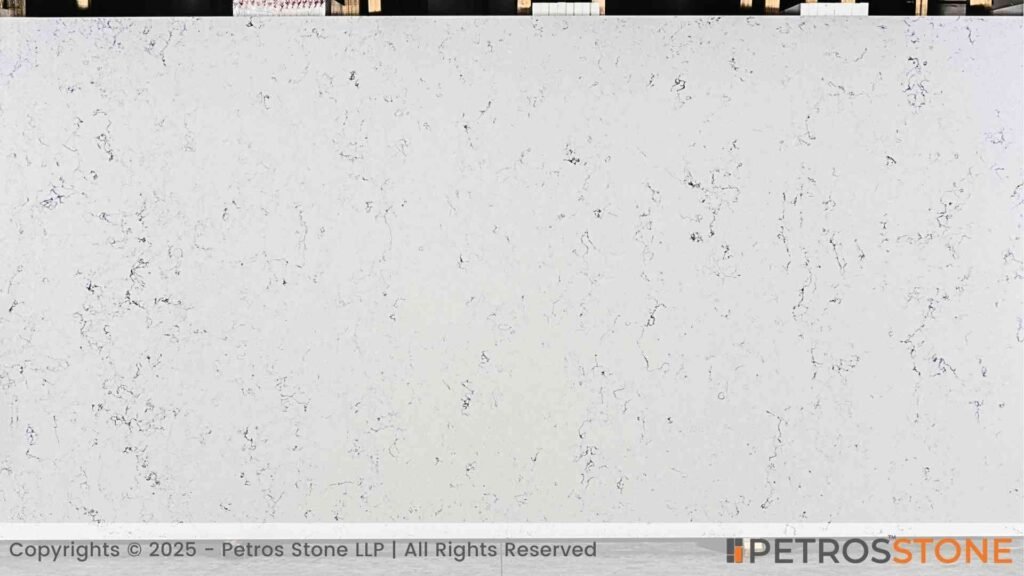

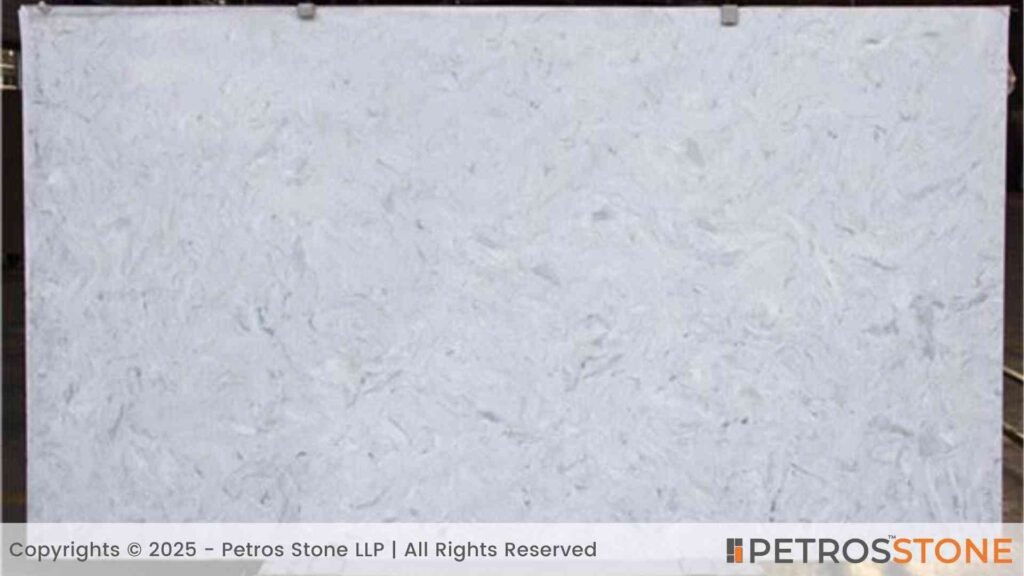

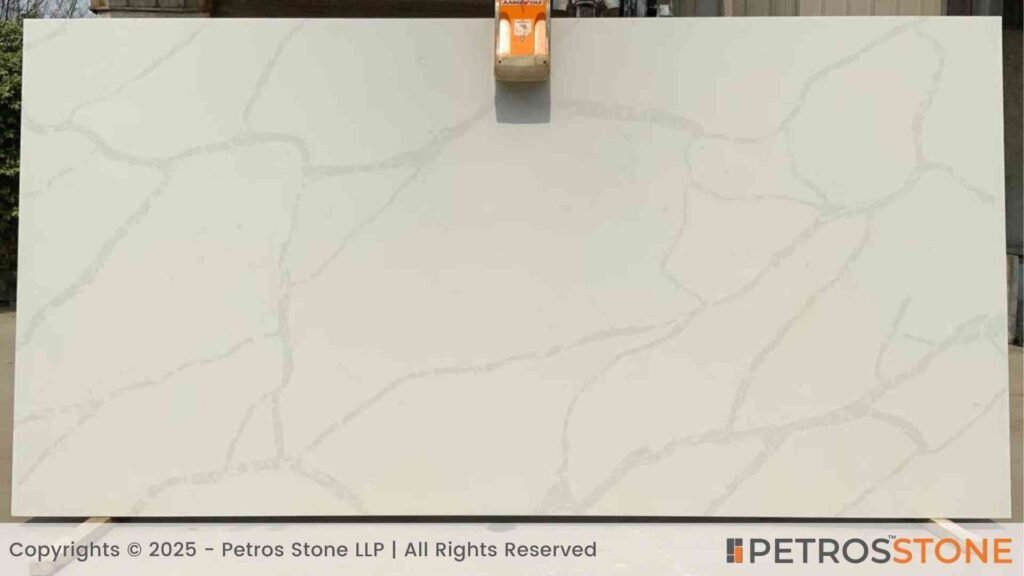

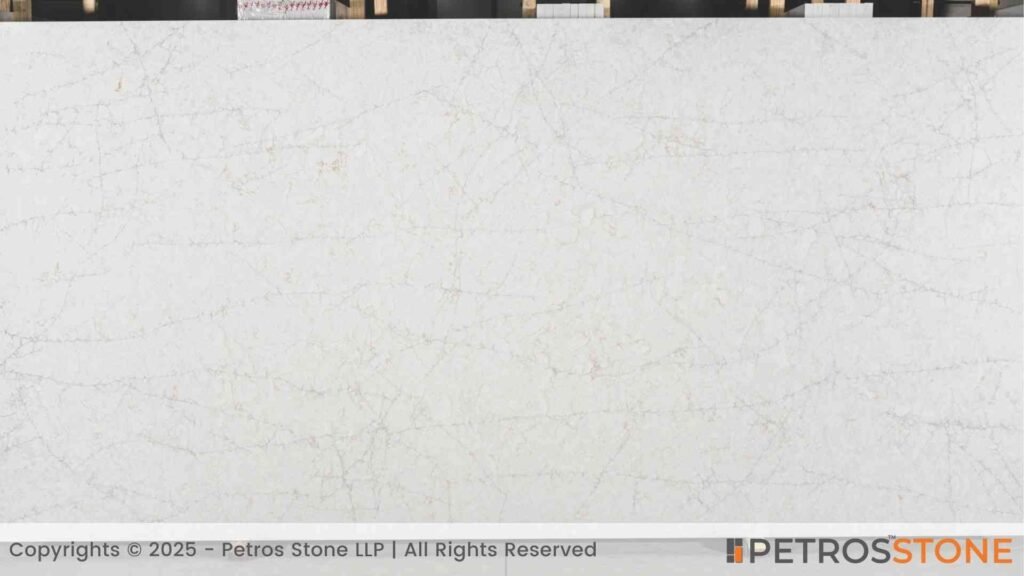

| 3 | Carrara Quartz Slab | INR 350-INR 450/sqft USD 3.5 – USD 5/sqft | Exact Price | Chat | |

| 4 | Marble Design Quartz Slab | INR 350-INR 450/sqft USD 3.5 – USD 5/sqft | Exact Price | Chat | |

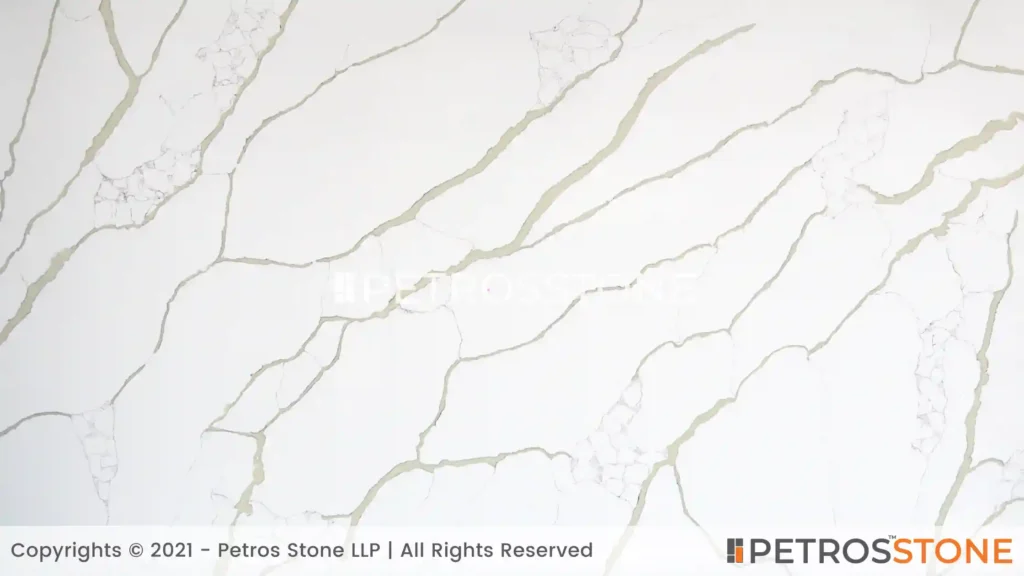

| 5 | Calacatta Quartz Slab | INR 450-INR 650/sqft USD 6 – USD 8.5/sqft | Exact Price | Chat | |

| 6 | Onyx Quartz Slab | INR 450-INR 850/sqft USD 6 – USD 9/sqft | Exact Price | Chat | |

| 7 | Exotic/Custom design Quartz Slab | INR 450-INR 850/sqft USD 6 – USD 9/sqft | Exact Price | Chat |

- How Many Quartz Slabs Fit in 1 Container?

- Why Should You Import Quartz Slabs from India?

- What is the Cost of Importing Quartz Slabs from India?

- What Should One Watch Out for While Importing Quartz from India?

- Quality Assurance of Quartz Imported from India

- Documentation and Clearance for Customs

- Duties and Taxes Applicable

- Let Petros® Stone do Everything for You!

How Many Quartz Slabs Fit in 1 Container?

105 Quartz slabs of size 1600x3200mm (jumbo) and 2cm thickness and 70 slabs of 1600x3200mm and 3cm thick.

Here is a complete detail of how many quartz slabs fit in one container:

| SLAB TYPE | SLAB SIZE | SLABS PER CONTAINER | SLABS PER CONTAINER | SQUARE METER PER CONT | SQUARE FEET PER CONT |

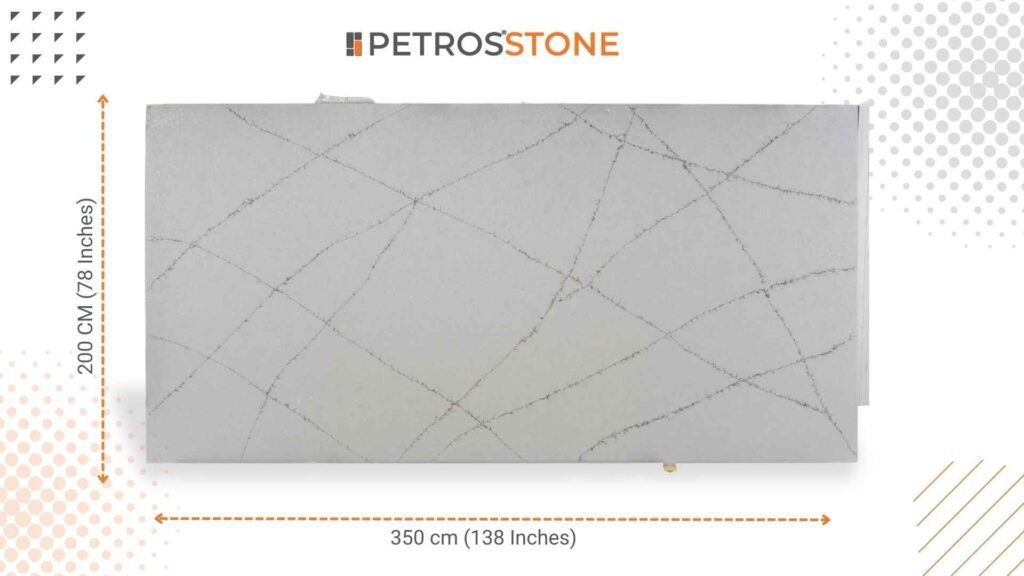

| SUPER JUMBO | 136″ x 75″ (2CM) 3450 x 1900 (2CM) | 84 | 1.9m x 3.45m x 84 slabs | 550.62 | 5926.87 |

| SUPER JUMBO | 136″ x 75″ (3CM) 3450 x 1900 (3CM) | 56 | 1.9m x 3.45m x 56 slabs | 367.08 | 3951.25 |

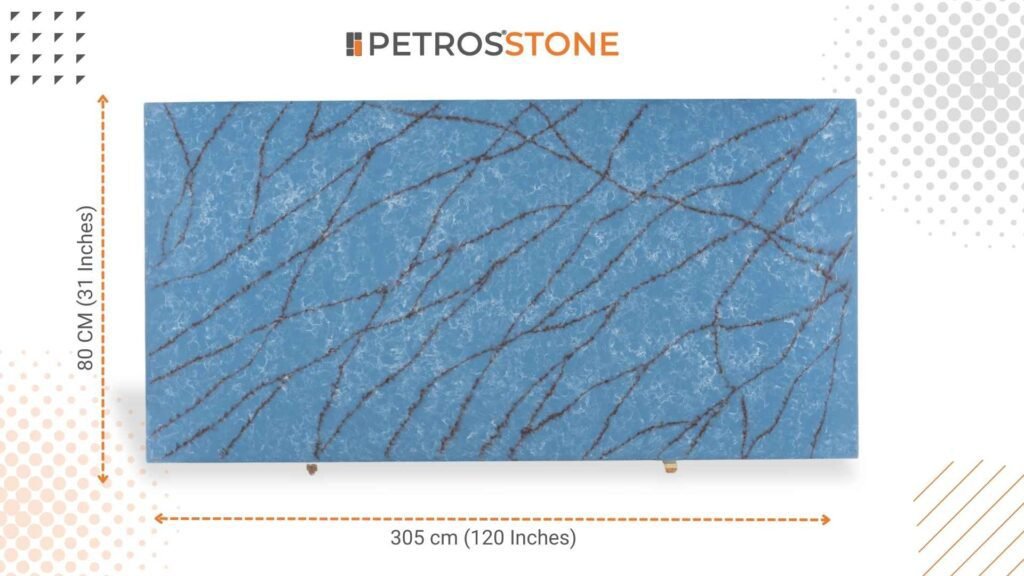

| JUMBO | 126″ x 63″ (2CM) 3200 x 1600 (2CM) | 105 | 1.6m x 3.2m x 105 slabs | 537.60 | 5786.73 |

| JUMBO | 126″ x 63″ (3CM) 3200 x 1600 (3CM) | 70 | 1.6m x 3.2m x 70 slabs | 358.40 | 3857.82 |

Why Should You Import Quartz Slabs from India?

The quality of the product can vary substantially as a result of inconsistent production conditions and technologies, despite the fact that prices are generally reasonable. There are several reasons why one should buy their Quartz slabs from India:

1. Exceptional Quality

Indian quartz slabs are distinguished by their exceptional quality, which is achieved through the implementation of stringent quality control standards and contemporary technology.

In order to guarantee exceptional durability and quality across a variety of applications, each slab is subjected to a thorough inspection process.

2. Less Environmental Impact

Numerous quartz quarries in India comply with stringent environmental regulations and employ sustainable mining techniques. These quarries endeavor to mitigate their environmental impact while simultaneously satisfying the demand for premium quartz by employing sources that adhere to ethical and environmentally favorable business practices.

3. Everyone Speaks English (almost)

English is an extensively spoken language in India, particularly in business settings. This enables more efficient communication between importers and suppliers, thereby reducing misunderstandings and enhancing collaboration throughout the import process. Many businesses find it simpler to negotiate cultural nuances when collaborating with Indian suppliers because of their shared business practices and values, which can result in more effective partnerships.

4. Cost-Effective

Quartz slabs in India offer exceptional value for the price by combining affordability and exceptional quality. Despite their superior quality, these slabs are frequently more cost-effective than comparable materials, rendering them an appropriate choice for a wide range of applications.

5. Ethical Considerations

Indian manufacturers are progressively adopting sustainable practices in the production of quartz slabs. This includes using eco-friendly materials and processes that minimize waste and pollution, making them a more ethical choice compared to some other countries where production standards may be lower.

6. Global Presence

India’s established position in the global quartz market should ensure that importers anticipate seamless transactions. The importing process is simplified by the dependability and efficacy of Indian suppliers, which are a result of their established export networks and commercial connections

7. Safety

The manufacturing of quartz slabs in India is subject to stringent health and security standards. This is especially pertinent given worldwide worries over silicosis and other health dangers associated with quartz manufacturing. Indian manufacturers are becoming more aware of these issues and are instituting mechanisms to protect workers from harmful silica dust exposure.

Want to know about the best quartz slab suppliers? read this article.

What is the Cost of Importing Quartz Slabs from India?

The cost of quartz slabs in India is subject to substantial fluctuations depending on the supplier, finish, and quality. The average price per square foot is between INR 250 – INR 550 or USD 3 – USD 6.5.

Shipping Fee

The shipping fee to major importers like the USA, Europe, Africa, and South America ranges from $2500-$5000 for 1 20’ container.

Customs Duties

The customs duties for the importation of quartz slabs into countries such as the United States may fluctuate. Depending on the specific classifications under HS codes, the import duty on quartz slabs may vary from 0% to 30%. Checking the most recent tariffs that are relevant to your particular import portal is advised.

Insurance

The customs duties for the importation of quartz slabs into countries such as the United States may fluctuate. Depending on the specific classifications under HS codes, the import duty on quartz slabs may vary from 0% to 30%. Checking the most recent tariffs that are relevant to your particular import portal is advised.

What Should One Watch Out for While Importing Quartz from India?

To guarantee a seamless and moral transaction, there are a number of important considerations to make while importing quartz slabs from India.

Companies that are Blacklisted

Make sure the businesses you are thinking about importing are not on any blacklists or have a track record of unethical behavior. Verify suppliers’ backgrounds, including their reputation, business history, and adherence to global trade laws.

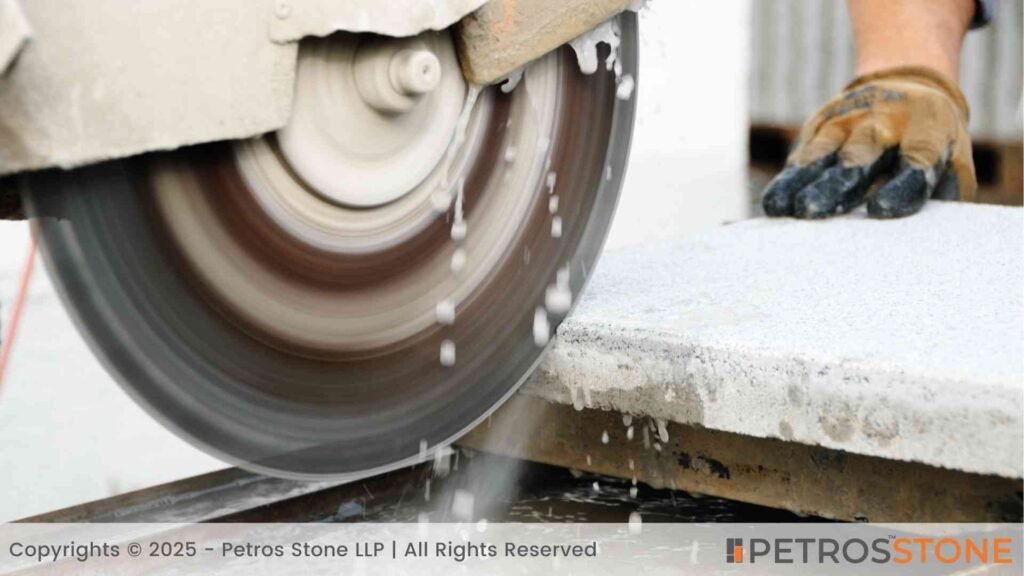

Manufacturers’ Machinery

Make sure the producers of quartz slabs use up-to-date, effective equipment. Equipment that is outdated or not properly maintained may provide lower-quality products.

Rules Against Dumping

When importing quartz from India, be mindful of any potential anti-dumping duties. These taxes are put in place to shield home businesses from overseas rivals who would undercut them on their goods.

Quality Assurance of Quartz Imported from India

As a natural stone manufacturer, we employ these guidelines to ensure that our products are of high quality after they are made.

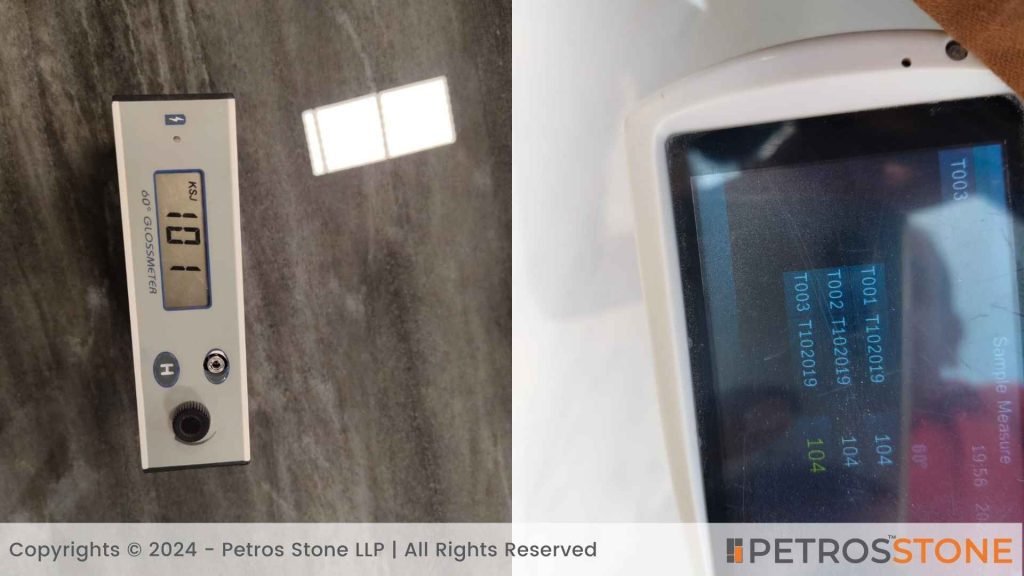

1. Examining the Slabs’ Polish Quality

The important point is that the level of polish of the stone is a crucial factor in determining its quality. It is often overlooked, but it significantly impacts the final appearance and overall success of the project.

2. Verifying the Granite or Marble Slabs’ Uniform Thickness

Granite and marble slabs must have uniform thicknesses, particularly for flooring applications. Depending on the stone’s intended use, a tolerance of 0.1 to 0.3 mm is acceptable, but anything beyond that could be problematic.

3. Match the Samples

Marble or granite slabs that match the samples that were submitted During the selection process, businesses must request that their suppliers submit a minimum of two samples. The procurement must always have one sample and the quality department must always have the other. Every block of the delivered goods needs to be compared against these samples.

4. Looking for Synthetic Colors or Coats

Artificial coloring can cover up flaws in the stone, such as fractures, lines, and patches. It may even alter its appearance entirely at times. To scrape the stone’s surface, use a tool rated 5–6 on Mohr’s Hardness scale. It indicates that the stone has an artificial color layer if it leaves no scratches.

Documentation and Clearance for Customs

A seamless customs clearance process depends on having the right paperwork, such as the Bill of Lading, Commercial Invoice, Packing List, and Certificate of Origin. Precise paperwork lowers the possibility of delays or customs detention by facilitating effective processing by customs officials.

Quartz Certification

The appropriate certification specific to the requirements of the country to which the slabs are being exported to is required. This certification is a representation of the Quartz slab’s quality, manufacturing process, ethical standards and other universal and country specific standards.

ISF Submission

For arriving ocean vessel import goods, importers are required under the ISF file to electronically transmit data to CBP. In order to prevent smuggling and improve cargo security and safety, this helps CBP and the Department of Homeland Security identify dangerous shipments.

The Bill of Lading

A bill of lading is a contract for the carriage of goods that is given to the shipper by a carrier or its agent. It may also be regarded as a receipt for goods that have been approved for shipment and needs to be shown when the delivery is made at the destination.

The three functions of this legal document are to serve as a contract between the shipper and the carrier, a receipt for the transportation of goods, and a document pertaining to the items’ title.

Bond for Customs

Similar to an insurance policy, a customs bond ensures that the relevant taxes and tariffs are paid to the country to whom the quartz is being exported. The term “bond” is most frequently used in the import/export sector. If the imported goods are worth more than $2500, this document is required. Two bond types in use are continuous transaction bonds and single-entry bonds.

Notice of Arrival

A legal document known as an Arrival Notice is given by the freight carrier when they reach the territory of another nation. Although it cannot be compared to a release certificate, it gives the consignee the information they need to complete the pending customs clearance and begin getting ready for the items’ collection.

Duties and Taxes Applicable

Anti-dumping

The anti-dumping duty regarding quartz slabs from India has been set around 3.19% for the majority of producers as of January 2025.

Standard Duty

Standard customs duties may be imposed on quartz slab imports in addition to anti-dumping duties. These can fluctuate depending on the country of origin and the specific trade agreements that are in effect.

Delivered Duty Paid (DDP)

Delivered Duty Paid (DDP) signifies that the seller is accountable for all expenses related to the delivery of products to a designated location. This encompasses the payment of all applicable duties and taxes, customs clearance, insurance, and shipping.

Let Petros® Stone do Everything for You!

Petros® Stone is regarded as one of the most exceptional brands for quartz countertops. This is owing to a number of distinguishing characteristics that separate it from its competitors.

Petros® Stone ensures that their products are constructed from high-quality materials by employing premium-grade quartz crystals that are sourced globally. The exceptional durability and longevity of their quartz countertops under intensive use conditions are a result of the combination of approximately 95% quartz and 5% resin. The company’s ISO 9001:2008 certification is indicative of its compliance with international quality management standards.

It has established itself as a reputable brand in the natural stone manufacturing and export industry, distinguished by its dedication to design excellence and innovation.

Feel free to get in touch for a free consultation, quote, and get a detailed understanding from our experts here at Petros®. Visit https://petrosstone.com/ or call +91-8446360361 and WhatsApp

Hi, I’m Shivangi,

With years of experience in the architecture and design space, I write to bridge the gap between material knowledge and practical application. At Petros® Stone, I create content that highlights the beauty, function, and impact of natural stones, helping homeowners and professionals make confident design decisions.

Explore my LinkedIn profile to learn more about my work!

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite