Mitred edge is one such finish. It is clean, contemporary and makes your countertops appear high-end and thick. However, is it worth it?

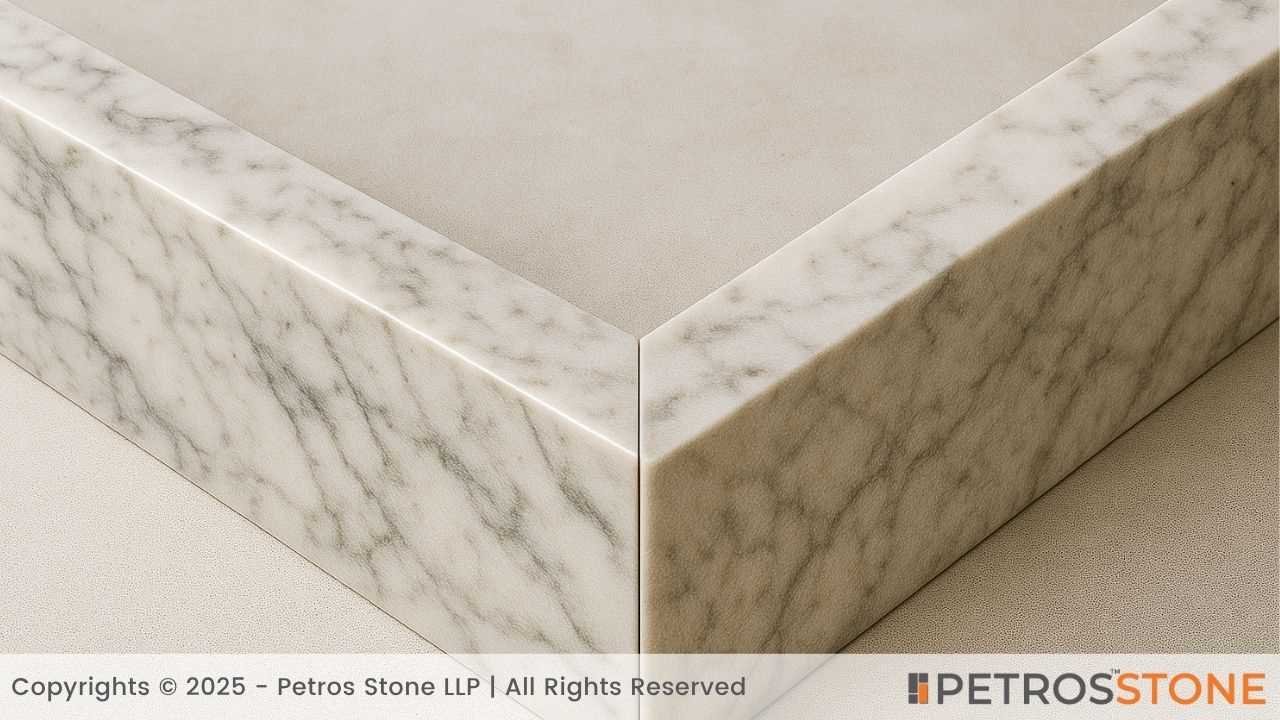

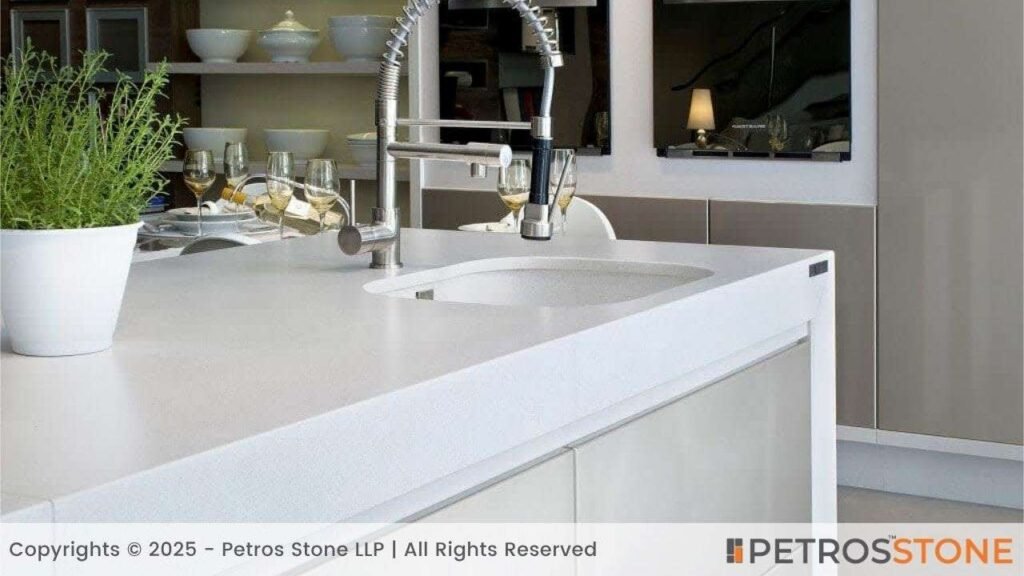

One of the most favoured trends in a contemporary kitchen as well as a bathroom is having quartz countertops. They are not only fashionable but they are alsomake the countertop look thicker. This especially works great for waterfall style islands.

If the marble countertop material has veining than they can be meticulously fabricated to make the “veins” flow through the coutnertop making it look seamless.

This article discusses all the details that you need to know about the mitred edge quartz/granite counter tops, such as what this type of quartz counter is, its comparisons to regular edges, the difference in cost, advantages, disadvantages and when you should—or shouldn’t—go for this style.

- Understanding Mitred Edge for Quartz Countertops

- Mitred Edge vs Regular Edge: Key Differences

- Cost Comparison: Mitred Edge vs Regular Edge

- Reliability and Durability

- When to Use a Mitred Edge

- When Not to Use a Mitred Edge

- Pros and Cons of Mitred Edge for Quartz Countertops

- Expert Tips Before Choosing Mitred Edge

- Let's Help you Decide

Understanding Mitred Edge for Quartz Countertops

What is a Mitred Edge?

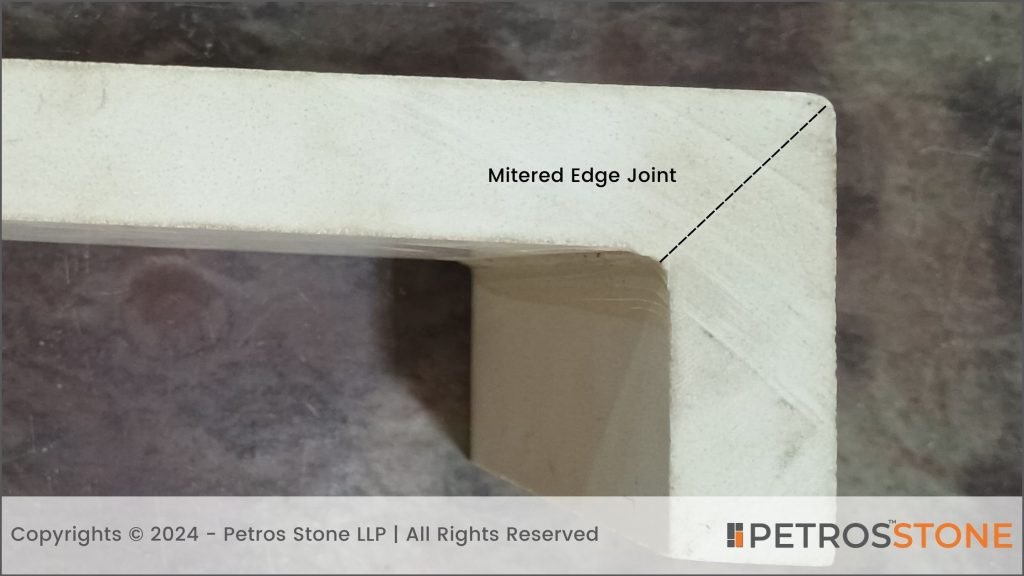

A mitred edge is one which has been created by cutting two pieces of quartz at an angle of 45 degrees and then attaching them to one another. They are connected to create a 90-degree angle that creates the impression of a thicker slab. This style makes the countertop appear as a solid block of stone, although it may consist of thinner pieces.

This method hides the real thickness of the quartz slab and provides a cleaner and more luxurious appearance to the counter.

How a Mitred Edge is Made

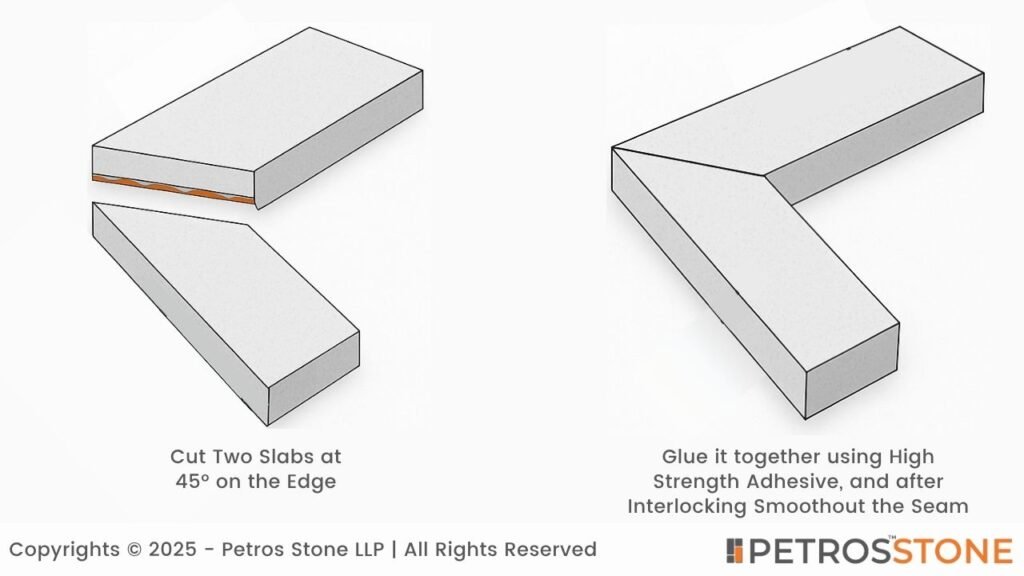

Mitred edge construction is accurate work. This is how it goes:

- A 45-degree cut is made on the edge of the quartz slab.

- Another piece of quartz is cut similarly to fit, but at 45 degrees also.

- The two pieces are glued together using high-strength adhesive such as epoxy.

- Following the interlock, the respective seam is smoothed out in order to create a virtually invisible seam.

This work requires craftsmanship in making it such that the seam does not show and the bond is robust.

What is the Use of a Mitred Edge?

Mitred edges are not just for show. They also have a number of practical and visual advantages:

- Gives an illusion of thickness: it is made to look like a thick piece, 2″ or even thicker.

- Provides a luxurious finish: Suited to high-end kitchens.

- Covering of seams and joints: Causes the edge to look seamless.

- Helps with modern design: Compatible with minimalistic and contemporary types.

In What Applications is Mitred Edge Employed?

The mitred edges are mostly applied in the following areas:

- Waterfall countertop: When the quartz is extended at the countertop down the floor.

- Surface polys: Increasing the thickness of the countertops, making thin slabs appear deeper.

- Step designs: If they are raised bar counters or tiered surfaces.

- Ornamental mouldings: Applied on bespoke furniture or partitions with quartz panels.

The perimeter countertop and kitchen islands can utilise this type of edge style.

Mitred Edge vs Regular Edge: Key Differences

Here is a simple comparison:

| Feature | Mitred Edge | Regular Edge |

| Look | Seamless, thick, modern | Basic, exposed slab thickness |

| Joint visibility | Hidden with glue | Exposed joint or visible seam |

| Design complexity | High – needs skilled fabrication | Simple – easier to install |

| Popular edge styles | Square, bevel, chamfer | Ogee, bullnose, pencil, bevelled, etc. |

| Durability at the joint | Strong when glued correctly | Durable but sometimes prone to chipping |

| Cost | High | Moderate to low |

| Repair difficulty | High – hidden seams are hard to fix | Easy – sanding and polishing are possible |

Aesthetic Comparison

The mitred edges appear to be cleaner. They provide a floating slab view that makes the quartz appear as a huge, thick block. Although practical, regular edges tend to expose the actual thickness of the slab and may appear bland in contemporary designs.

| Aspect | Mitred Edge | Regular Edge |

| Visual Appeal | Seamless, elegant, and premium | Functional but basic |

| Thickness Illusion | Appears thicker than it is | Shows true slab thickness |

| Best For | Modern, high-end, and open-space designs | Traditional, compact, or budget-conscious spaces |

| Edge Seam Visibility | Almost invisible if well-crafted | The seam or edge is often visible |

Functional Comparison

Both varieties of edges work fine with everyday usage. But mitred edges can be smoother on the seam without glue. Constant edges can be lighter to preserve and do touch-ups.

| Feature | Mitred Edge | Regular Edge |

| Durability at Edge | High with proper glueing, but seam-sensitive | Generally durable with no seam dependency |

| Ease of Maintenance | Requires careful cleaning around seams | Easier to maintain and touch up |

| Repair Simplicity | Difficult due to hidden seams | Easier to repair or re-polish |

| Seam Weakness Risk | Higher if not fabricated properly | Low |

Edge Style Variants Compared

Mitred edges are normally accomplished with less complex edge profiles, square or slightly bevelled. Traditional designs are more appropriate with regular edges since decorative edges, such as ogee or bullnose, are easier to create.

| Edge Style | Available in Mitred Edge | Available in Regular Edge |

| Square | ✔ | ✔ |

| Bevelled (simple) | ✔ | ✔ |

| Ogee | ✘ | ✔ |

| Bullnose / Half Bullnose | ✘ | ✔ |

| Pencil | ✘ | ✔ |

| Double-stacked | ✘ | ✔ |

Cost Comparison: Mitred Edge vs Regular Edge

Factors Affecting Cost

Many factors affect the price of a mitred edge, which are as follows:

| Cost Factor | Mitred Edge | Regular Edge |

| Fabrication Complexity | High – Requires 45° cuts, glueing, alignment, and polishing | Low – Simple cutting and edging |

| Material Usage | More – Additional quartz needed for edge wrap | Standard – No extra material beyond slab thickness |

| Labour Skill Requirement | High – Needs experienced stone fabricators | Basic – Can be done by most countertop installers |

| Time to Install | Longer – Precision work increases fabrication and installation time | Short – Faster to produce and install |

| Waste/Breakage Risk | Higher – Joint seams are fragile if mishandled | Lower – Fewer risks during handling and transport |

| Tooling & Adhesives | Specialised adhesives and finishing tools are required | Standard tools and adhesives suffice |

Estimated Cost Breakdown

| Edge Type | Material Cost | Labor Cost | Total Additional Cost (per meter) |

| Regular Edge | Included | Basic | ₹0–₹500 |

| Beveled Edge | Slightly more | Moderate | ₹500–₹1,000 |

| Mitred Edge | Higher | High | ₹2,500–₹4,000 |

| Waterfall Mitre | Highest | Very High | ₹4,000–₹7,000 |

Note: Prices vary based on quartz brand and fabricator location.

Reliability and Durability

Joint Strength

Mitred edges are strong when they are well-made. However, a low quality of manufacturing may result in weak points in the joints. Suitable adhesive and firm binding are very essential.

Resistance to Cracks and Chips

Quartz is usually strong, yet mitred edges are weaker at the seam. Joints are susceptible to cracks when they are struck hard. Considering this aspect, regular edges tend to be a bit more lenient.

Maintenance and Repairs

- Mitred edge: More difficult to fix since the seams are concealed.

- Regular edge: Sanding or re-polishing is easier in the case of chips.

When the mitred edge breaks, it usually needs the whole edge to be replaced.

When to Use a Mitred Edge

Ideal Applications

Here is a brief look at where the places with mitred edges work best for quartz countertops:

| Situation | Why Mitred Edge is Suitable |

| Thick Look Illusion | Creates the appearance of a thick, solid slab without using extra-thick quartz |

| Waterfall Countertops | Offers a seamless flow from the countertop to the floor for a dramatic look |

| Modern Aesthetic | Enhances clean lines and minimal seams in contemporary kitchen designs |

| Open Kitchen Designs | Adds visual weight and becomes a centrepiece in open-concept layouts |

| High-End Renovations | Complements luxury finishes and increases perceived value in upscale projects |

| Vein Continuity | Maintains consistent pattern flow across vertical and horizontal surfaces |

Visual Impact in Large Spaces

- Mitred edges add to the visual volume of countertops, particularly in open-plan kitchens.

- They give a strong blockish feel that gives depth as well as grace.

- Other places that are perfect are large islands, whose thickness can serve as a powerful design reference.

- Waterfall designs of mitred edges bring the eye down, creating vertical flow.

- Assists in making basic countertops become centrepieces in large-scale rooms.

- Adds to modern and minimalist styles to present smooth and clean lines.

- This is particularly successful in the luxury or high-end house where the looks are as important as the use.

When Not to Use a Mitred Edge

Budget Constraints

The cost of mitred edges can add 15 to 30 per cent to the cost of your countertops. In case you have a limited budget, it would be better to leave it and select a regular edge variant.

Small Kitchens and Compact Spaces

The dramatic effect of a mitred edge will be unnoticed in small kitchens. The increased expenses might be unnecessary in small areas.

Skilled Labour Unavailability

Unless your local stone fabricator has experience working with mitred edges, do not go there. An unclearly performed mitred joint may spoil the appearance and even the strength.

Pros and Cons of Mitred Edge for Quartz Countertops

Pros

- Classy, sleek, and exclusive appearance.

- Smooth look of contemporary kitchens.

- Changes thin circles into thick circles.

- Perfect in islands and open areas.

- Combines well with waterfall edges.

Cons

- High cost to produce and set up.

- It takes a longer duration to complete.

- Easy to break at seams when done poorly.

- It is tough to repair.

- Limited edge styles are available.

Table: Situational Pros and Cons of Mitred Edge Quartz Countertops

| Scenario | Why It’s a Pro | Why It Can Be a Con |

| High-End Kitchen Renovation | Enhances luxury appeal; matches modern interiors | Costs more than regular edge options |

| Quartz Slabs with Veining or Patterns | Allows continuous pattern flow across joints | Requires precise alignment; risk of mismatched seams |

| Large Open-Concept Spaces | Adds visual weight; makes the island a centrepiece | Needs more quartz and skilled labour |

| Designing a Waterfall Island | Seamless vertical drop looks sleek and unified | More fabrication time; joints must be flawless |

| Rental or Budget Property | It may help increase perceived property value | ROI may not justify the cost in lower-value properties |

| DIY or Rural Area Projects | Visually stunning for custom projects | Skilled labour might not be available locally |

Expert Tips Before Choosing Mitred Edge

- It is always necessary to analyse the previous experience of the fabricator.

- Before proceeding, ask to see a sample mitred seam.

- Ensure that the alignment of patterns or veins is symmetrical on the edge.

- Apply quality adhesives to obtain a lasting strength.

- Mitred edges should be avoided where corners may receive impact (e.g. around children or well-trafficked areas).

- Include an extra budget and a timeline buffer.

- Note that designs based on Waterfall are twice as expensive, so budget accordingly.

- Do not get mitred edges mixed up with laminated edges or doubled-up edges; they are not the same.

Let’s Help you Decide

Your plain quartz countertops can become luxurious with a mitred edge. It creates space, sophistication and a smooth contemporary look, particularly in affluent kitchens or expansive, open designs. Its capability to give an impression of size in its appearance, yet keeping a clean line, makes it a preferred choice of designers and architects who seek to achieve a luxurious look.

Nevertheless, this edge style is not free of cost. More expenses are required to create and fix it, additional material is needed, and experienced specialists are necessary to do the job properly. Otherwise, the seams may be visible or even fail with time.

Choose Mitred Edges When

- You are planning a luxury or high-end kitchen.

- You are most concerned about visual impact and style.

- You have the funds to cover the increased expense and the extended schedule.

- You are interested in having a waterfall countertop or focal point island.

- Your room will enjoy the alias of having thicker, bolder countertops.

Opt for Regular Edges When

- You are operating with a slim or fixed budget.

- The counter is small and hidden, or functional.

- Local skilled mitred-edge fabricators are not available.

- You want simplicity, speed and reduced maintenance.

- You are fitting in countertops in rental or secondary properties.

Both options are good, but choose the one that fits your space, style, and budget.

Feel free to get in touch for a free consultation, quote, and get a detailed understanding from our experts here at Petros®. Visit https://petrosstone.com/ or call +91-8446360361 and WhatsApp

Hello!

I’m Dr Mridali, a content writer with a background in dentistry and a passion for turning complex topics into clear, engaging stories. From healthcare to architecture, I create blogs that inform, educate, and connect with readers. With every piece, I aim to blend accuracy with creativity to make information truly valuable.

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite