Porcelain slabs are getting very popular because of their designs, affordability, and luxury. But the most difficult problem most people face is – fabricating these slabs to look clean, finished and luxurious. Porcleain slabs are not very easy to fabricate and finish, owing to their hard and brittle nature.

In this guide, we will simplify the cutting process for you, give you some excellent tips and techniques to avoid chipping, and further more give you the necessary information neded to make sure your porcelain countertops come out looking absolutely perfect!

By learning about the right techniques and safety measures, you will be more aware on how to cut, finish, and fabricate porcelain slabs and porcelain countertops with safety and precision.

- Cutting Large Porcelain Slabs

- Best Tools to Cut Porcelain Slabs?

- Best Drill Bit For Cutting Holes In Porcelain Slabs/Countertops

- What is the Best blade for cutting Porcelain?

- What Saw is Best for Cutting Porcelain?

- How To Prevent Chipping of Porcelain Slabs When Cutting?

- How to Polish Porcelain Slab Edges?

- Safety Measures To Follow Before Cutting Porcelain Slabs

- How To Make Clean Joints in Porcelain Slabs?

- Should You Buy Porcelain Slabs?

- People May Also Inquire!

Cutting Large Porcelain Slabs

Cutting in the Factory:

If you have access to a factory with bridge cutters and high-end equipment, these instructions are for you:

Cutting Porcelain Slabs with Waterjet Cutting Machine

- Use a waterjet cutting machine – this is the best and easiest way to cut porcelain slabs.

Cutting Porcelain Slabs with Bridge Cutter (Blade)

- If you have a bridge cutter, then follow these instructions.

- Cut the Opposite Side: Lay the slab upside down with the rougher side exposed

- Make sure you prime the surface before cutting – by this we mean slowly grazing the blade slightly into the surface.

- On the second or third pass, dig deeper into the surface to complete the cut

- Avoid curved cuts unless you have a waterjet cutter

- Use diamond bit blades for cutting, if possible, made in Italy by machine manufacturers,

- Keep it Wet: It is necessary to use water while cutting the slabs to keep the blade cool and prevent chipping.

Cutting and Finishing Porcelain at the Project Location:

1. Preparation of Porcelain Slabs

Select the Right Tool Based on Cut Type

- For Straight Cuts – Use a wet tile saw or a manual tile cutter for clean and precise cuts.

- For Curved Cuts – Use an angle grinder with a diamond blade or a wet saw to cut smoothly along curves.

- For Holes (Pipes/Fittings) – Use a hole saw for larger openings or a tile nipper for small adjustments.

Gather Safety Equipment

- Wear safety glasses to protect your eyes.

- Use a dust mask to avoid inhaling dust.

- Wear gloves for a better grip and protection.

- If using power tools, use hearing protection.

Mark the Cutting Line

- Use a pencil or grease marker to mark where you want to cut.

- A straightedge or ruler helps to keep lines accurate.

- For curved cuts, use a template or a compass.

2. Cutting Methods for Porclain Slabs

A. Straight Cuts (Wet Tile Saw / Manual Tile Cutter)

Place the Tile on the Cutter

- Align the marked cutting line with the blade/guide.

Score the Tile (If using a manual cutter)

- Apply firm pressure on the tile cutter handle to score the surface once.

Snap the Tile (For Manual Cutter)

- Press down gently to snap along the score line.

Use a Wet Tile Saw (For Cleaner Cuts)

- Slowly guide the tile through the blade with steady pressure.

- Ensure the water supply is functioning to keep the blade cool.

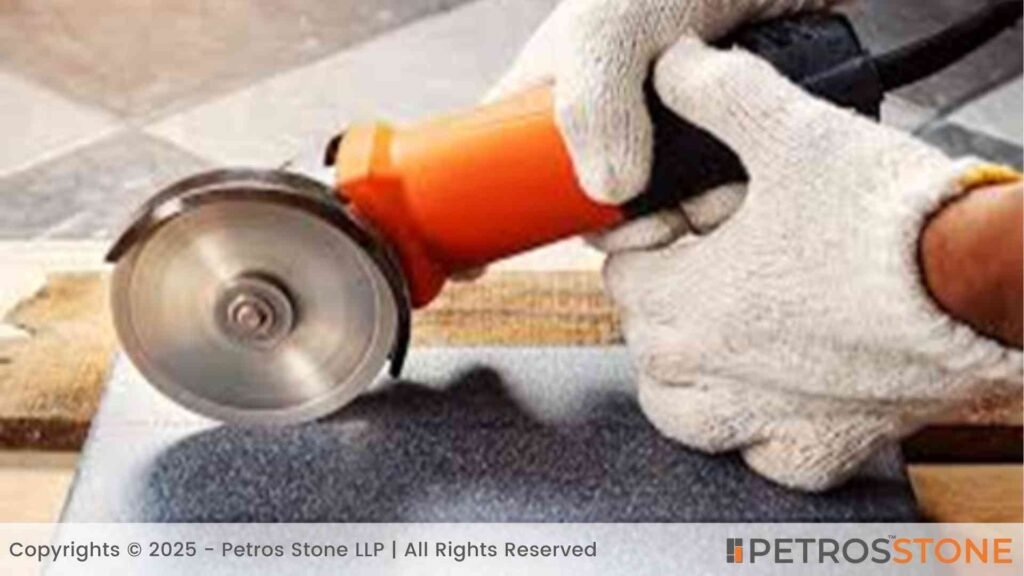

B. Curved Cuts (Angle Grinder with Diamond Blade)

1. Secure the Tile on a Workbench

- Use clamps or a non-slip mat to prevent movement.

2. Start Cutting from the Edge

- Use an angle grinder with a diamond blade to cut along the marked curve.

- Make small passes instead of trying to cut in one go.

3. Smooth the Edges

- Use a tile file or sandpaper to refine the curve.

C. Holes for Pipes/Fittings (Hole Saw / Tile Nipper)

1. Use a Diamond-Coated Hole Saw

- Position the drill at a 45-degree angle to start, then slowly move to 90 degrees.

- Apply light pressure to avoid cracking.

2. Use a Tile Nipper for Small Adjustments

- For fine-tuning, carefully nip away small sections and smooth them with sandpaper.

Best Tools to Cut Porcelain Slabs?

It is important to keep the right tools ready before you start cutting a porcelain slab. Here are some essential cutting tools you will need:

Angle Grinder with Diamond Blade

An angle grinder with a diamond blade is a useful tool for cutting porcelain slabs, especially for creating intricate shapes and details. It is versatile and allows you to adjust the speed according to what you need. You might find it handy to make minor adjustments on-site during installation. This is mainly used for bathrooms where you will need to cut around round objects.

The best thing is that this tool is affordable and portable, so it is easy to carry around. Just remember that it requires some skill to use, as it may not be as precise as other tools. Hence, it can take some time to get the job done.

Bridge Cutter with Large Blades

If you want consistency and quality in your cuts, a bridge cutter is an excellent choice. This cutter is a powerful tool that provides accurate and automatic cuts to the slabs. It is perfect for factory environments and works well with large slabs, Plus, it delivers clean and precise sections. However, users must keep in mind that it can’t make curved cuts, so it is best used for straight lines only.

Waterjet Cutter

The waterjet is an amazing tool! If you need fast and precise cuts, the waterjet is the best option to pick. It cuts the porcelain slabs quickly and accurately using water and a high-pressure jet. It is used to cut precise shapes and designs. This tool can handle any contour and this property makes it ideal for creative projects where you want unique patterns.

Best Drill Bit For Cutting Holes In Porcelain Slabs/Countertops

If you need to drill through porcelain tiles, the best choice is a diamond drill bit. Porcelain is super hard, so regular drill bits won’t work—they might even crack the tile. Diamond-tipped bits are strong enough to cut through smoothly. Just remember to go slow, apply light pressure, and use water to keep things cool. This will help you get a clean hole without causing any damage to the slab. No matter whether you are hanging a shelf or simply fixing it, the right drill bit will make the job easy.

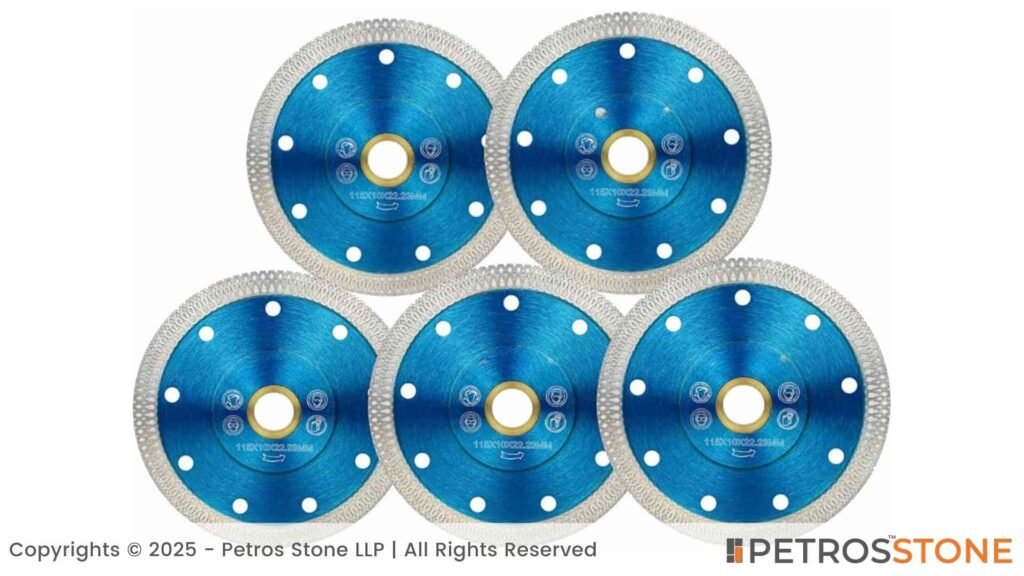

What is the Best blade for cutting Porcelain?

For any blade, using diamond bits works best. There is no better option to cut these slabs than with a diamond blade saw.

And, if you are using a waterjet, you are in luck because you will not need a specific blade. Waterjet is the best machine to cut porcelain slabs. The high-pressure water can cut through porcelain without any extra tools and offer you For any blade, using diamond bits works best. There is no better option to cut these slabs than with a diamond blade saw.

And, if you are using a waterjet, you are in luck because you will not need a specific blade. Waterjet is the best machine to cut porcelain slabs. The high-pressure water can cut through porcelain without any extra tools and offer you flexibility in your designs.

What Saw is Best for Cutting Porcelain?

The best saw for cutting porcelain is a wet tile saw. It uses water to keep the blade cool, which helps prevent chipping and gives you smooth cuts.

You can also use a tile cutter with large diamond blades, which works well for straight cuts. If you are using an angle grinder, it is fine to choose a blade size between 4.5 and 7 inches. This size is good for small cuts and gives you good control. For a bridge cutter, go for a blade that is 10 to 12 inches to cut larger porcelain slabs precisely!

How To Prevent Chipping of Porcelain Slabs When Cutting?

Below we will discuss the various hacks that can help you prevent chipping when cutting porcelain tiles:

1. Use the Right Bit: Sharp is Smart!

Imagine trying to cut a tough steak with a butter knife—it’s just not going to work! So, this is why, using the right bit is super important when cutting porcelain. A diamond bit is what you need because it is strong enough to cut through porcelain easily and helps avoid chipping.

2. Provide Support: Clamp It Down!

Is it easy to cut on the marked line when something is not fixed in one place? Not, at all. To prevent the slab from moving here and there, it is vital to provide solid support for your slab. You can use clamps to hold it in place while you cut. This stability helps prevent any slipping that could lead to rough edges.

3. Rough Side First: Grip for Success!

Have you ever tried to hold onto something slippery? Tried to pick the slippery soap bar in the bathrooms? That’s how cutting works, too! If your porcelain slab has a rough side, you must start by cutting it there. The texture gives you a better grip and makes it easier to cut straight. Follow this step and reduce the chance of chipping.

4. Prepare the Surface: A Clean Start!

Before you begin, it is best to take a moment to inspect your slab. Is there dust or debris that could get in the way? If so, get a dusting cloth and wipe that first. Cleaning and prepping the surface ensures you are set up for success.

5. Keep It Cool: Lubricate to Prevent Chipping!

Overheating can be a sneaky culprit when cutting porcelain. Just like you wouldn’t want to burn your hand on a hot stove, your blade needs to stay cool too! Using water or lubrication while cutting keeps the blade from overheating. This simple step goes a long way in preventing chipping or cracks.

How to Polish Porcelain Slab Edges?

Cutting the edges is not sufficient to give a clean look! You will need to polish the edges to make it look shiny. Here are some simple steps to help you achieve that fresh and glossy finish:

- Polish for Shine: If you have a full-bodied tile, this means the color is the same throughout. So, you can polish the edge easily and make it more appealing.

- make sure to polish all the passes – starting with a rougher grit polish all the way upto 2000+ grit without skipping steps.

- Use Baking Soda Paste: One of the great tips is to use baking soda paste or specialized tile polish. It is easy to make! Just mix baking soda with a little water to form a paste and scrub it to brighten up your edges.

- Combat Discoloration: To fix discoloration on the edges, apply the baking soda paste and let it sit for a bit. After a while, scrub gently with a soft cloth or sponge and rinse it off.

- Scrub Gems: Don’t forget to scrub the tiles and grout lines, too! Simply, use soft cloths, sponges, or even an old toothbrush to clean them to make your entire surface sparkle and shine.

Safety Measures To Follow Before Cutting Porcelain Slabs

The list of essential protective gear provided above isn’t just for your information; it is crucial to use all those for safety as well!

- Wear Protective Gear: Always wear gloves and goggles to protect your hands and eyes. Ear protection is also a good idea, especially if you are using loud tools.

- Mask Up and Ventilate: It’s wise to wear a mask while cutting. Doing this in a well-ventilated area, preferably outside, can help you avoid breathing in dust, which isn’t good for your lungs.

- Stay Focused: Always keep your focus when using power tools. They can be dangerous if not handled correctly, so take your time and be careful.

- Use Scrap Wood: If you are using a wet saw, place a piece of scrap wood under the tile. This will keep your fingers away from the blade and reduce the risk of accidents.

How To Make Clean Joints in Porcelain Slabs?

Not only will you want to cut porcelain slabs, but sometimes you might need to join them together as well! Here are a few common ways to do that:

- Direct Joint:

- Make sure the cut is clean – a clean cut with ensure a clean joint

- Make sure there’s no gap – line them up and inspect for any gaps.

- You simply line up the edges of the slabs so they touch directly.

- Use a transparent compound and mix some colouring to match the base colour of the porcelain

- Mix it with epoxy

- Clamp them against each other without any gaps

- Wait till the epoxy has cured

- Polish the joint to flush them. This creates a seamless single surface,

- Mitre Joint:

- Cut the edges at a 45-degree angle for a sharp corner.

- Align both pieces carefully so they fit perfectly.

- Apply epoxy or strong adhesive to secure the joint.

- Clamp the slabs tightly to hold them in place.

- Let it dry, then polish for a perfect and smooth finish.

- Sandwich Joint:

- Apply grout between the slabs to bond them together, just like a sandwich.

- Keep the spacing even so the grout sets properly.

- Use high-quality and flexible grout for better strength.

- Press the slabs firmly together to remove air gaps.

Should You Buy Porcelain Slabs?

If you are looking for help in deciding whether you should work with porcelain slabs or not or if you are looking for expert assistance regarding porcelain slabs, feel free to get in touch with us.

Now you know how to cut Porcelain slabs, the best tool for cutting porcelain slabs, and the techniques to reduce the chances of chipping. Hope this guide was useful for you!

Don’t forget to take a look at our stunning options in Porcelain Countertops and Marble Countertops for your home project! Turn your dream home into reality at the most reasonable prices.

People May Also Inquire!

Q. How do you cut porcelain slabs without chipping?

Most professionals recommend using a strong diamond blade wet saw tile cutter to cut porcelain slabs. This tool helps ensure clean cuts and reduces the chances of chipping during the cutting process.

Q. What is the best tool to cut porcelain slabs?

If you are planning to use any electric cutter, whether wet or dry, it is essential to use a diamond blade. It ensures effective cutting and helps to maintain the slab’s integrity.

Q. What blade is best for cutting 20mm porcelain slabs?

The TPL-EXT PRO blade is the best choice for cutting 20mm porcelain slabs. It is specifically made to handle thicker materials to provide smooth cuts.

Q. How do you stop porcelain from chipping when cutting?

To prevent chipping, you must cut the porcelain tile using a strong wet diamond saw. The wet process keeps the blade cool and reduces the risk of damage to the tile.

Q. Are porcelain slabs hard to cut?

Yes, porcelain slabs are hard to cut because they are brittle and hard in nature. You can use the best tool for cutting porcelain slabs and make the job easy.

Feel free to get in touch for a free consultation, quote, and get a detailed understanding from our experts here at Petros®. Visit https://petrosstone.com/ or call +91-8446360361 and WhatsApp

Hello!

I’m Varsha, with a deep interest in architecture and years of content writing experience, I explore how natural stones like granite and marble shape beautiful, functional spaces. At Petros® Stone, I share insights that help readers appreciate the design potential and timeless appeal of stone.

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite