Granite is one of the oldest and most revered natural stones, admired for centuries for its strength, beauty, and lasting value. From ancient temples and monuments to today’s kitchens, bathrooms, and even airports, granite tiles have stood the test of time across generations and spaces.

Yet, one of the most common questions buyers ask before making a purchase is:

“What size and thickness of granite tile should I choose?”

The answer depends on several factors: your intended application (floor, wall, or countertop), the desired look, the expected load on the surface, and, of course, your budget.

In this article, we’ll break down the standard sizes and thicknesses of granite tiles, explain how to choose the right dimensions for your specific needs, and help you make an informed decision. By the end, you’ll have a clear understanding of what granite tile size and thickness best suits your project.

Granite Tile Sizing Standards

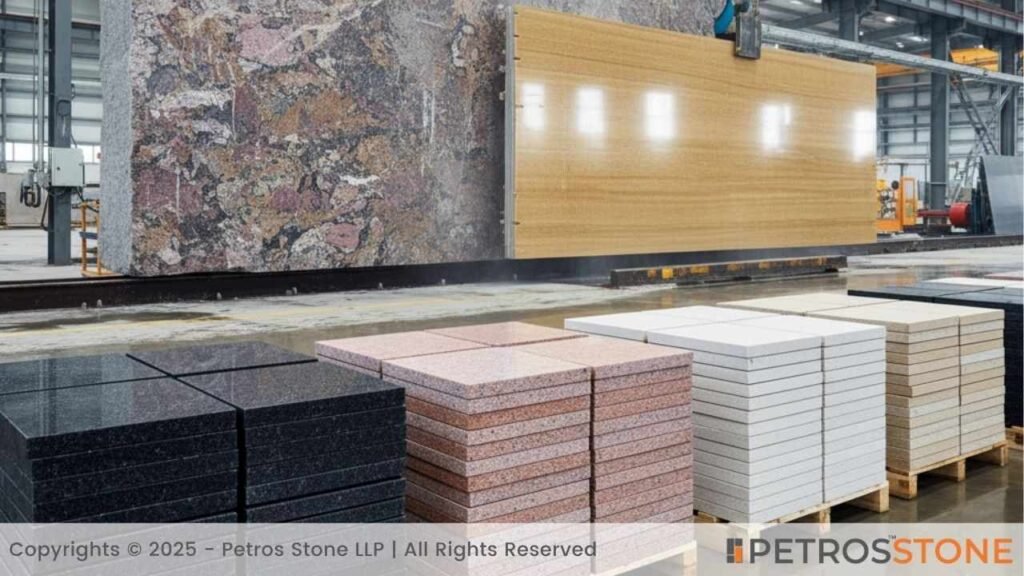

Granite tiles are manufactured by slicing large blocks of stone carved out of the natural deposits. First, these blocks are cut into slabs, which are subsequently subdivided into tiles of different sizes. The stone industry is subject to standard sizing to maintain consistency and ease production. Standardization helps all those concerned in the manufacturing industry, installers, and end-users.

Importance of Standardization

- Consistency: Standardized tiles can be broken into uniform, tiny tiles, and there is a minimum number of empty spaces. This gives a clean and professional appearance in both the flooring and the wall installations.

- Speed: The installers have an opportunity to work more rapidly as the standard sizes do not need as many cuts and modifications during installation. This saves on the amount of time spent on labor and improves the efficiency of the project.

- Cost Efficiency: With the use of standard sizes, the manufacturers lessen wastage of materials during cutting and processing, which reduces the final cost of production.

- Easy Replacements: When a tile gets destroyed, a replacement is easy to obtain since standard-sized tiles are commonly found in the market.

- International Trade: Unified dimensions allow suppliers and buyers internationally to trade in tiles, therefore, making logistics and packing easy.

Tiles vs Slabs vs Cut-to-Size

Tiles

These are smaller sizes, say, 30×60 cm or 60×60 cm, and are mainly employed in floorings, walls, and decorative surfaces.

Slabs

Thick sheets, typically of 240×120 cm or more, primarily decorated by countertops, staircases, and wall covering.

Cut-to-Size

Tiles that are designed to be used in particular uses like stairs, countertops, columns, or artistic wall panels. They are configured to meet precise project needs.

| Type | Typical Dimensions | Primary Applications | Advantages | Notes/Considerations |

| Tiles | 30×30 cm to 120×120 cm | Flooring, bathroom walls, kitchens | Easy to install, widely available, cost-effective | Lighter, suitable for DIY installation; more grout lines |

| Slabs | 200×100 cm to 300×150 cm | Countertops, large wall panels, stairs | Fewer joints, premium look, ideal for large surfaces | Heavy, requires machinery and skilled handling |

| Cut-to-Size | Custom dimensions | Stair treads, columns, decorative panels | Fully tailored to project needs, precise fit | Higher cost, longer lead time, specialized fabrication |

Metric vs Imperial Systems

The granite industry operates with both imperial and metric measures:

- Metric (cm, mm): 30×60 cm, 60×60 cm, 60×120 cm.

- Imperial (inches): The most frequently used sizes are 12×12, 18×18, and 24×24.

Although both systems are popular, the metric system predominates in international trade, which can facilitate easier manufacturing, packaging, and world supply chain operations.

Common Granite Tile Sizes

Granite tiles come in a variety of sizes. Each size has its own strengths, weaknesses, and best applications. Let’s go one by one.

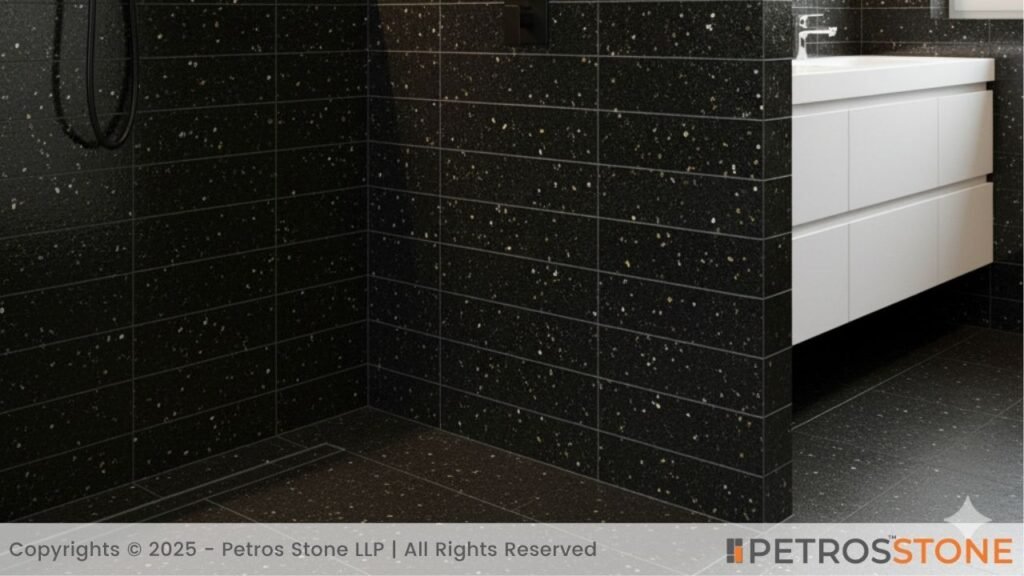

30×60 cm (12×24 inch)

- Common use: Bathroom floors, walls, kitchen and backsplashes.

- Advantages:

- Easy to handle and install.

- Fits well in smaller rooms.

- Minimal cutting needed in tight spaces.

- Limitations: Not ideal for very large areas as it creates more grout lines.

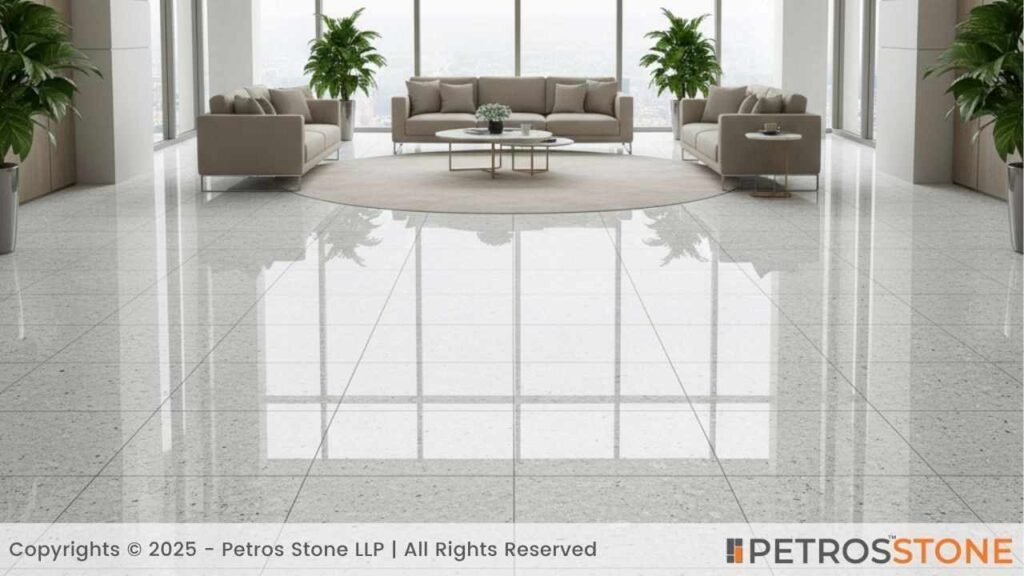

60×60 cm (24×24 inch)

- Common use: Living rooms, offices, lobbies.

- Advantages:

- Balanced size – not too small, not too big.

- Gives a modern square layout.

- Works well for both residential and commercial floors.

- Limitations: Needs proper leveling during installation.

30.5×61 cm (Imperial 12×24 inch)

- Common use: US and North American projects.

- Advantages:

- Matches imperial measurement standards.

- Easy to source locally in the US.

- Limitations: Limited global availability compared to metric sizes.

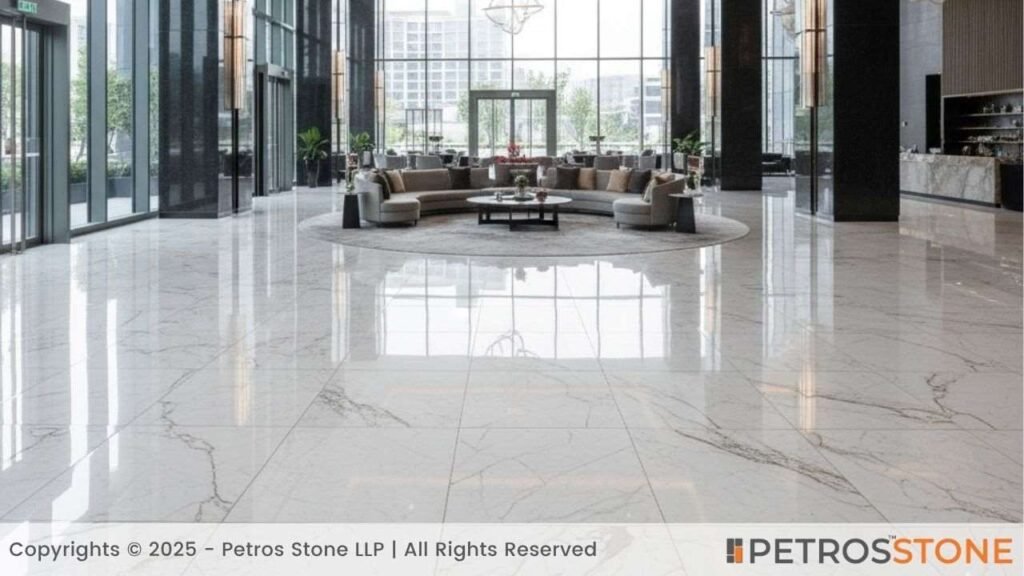

60×120 cm (24×48 inch)

- Common use: Modern homes, large wall cladding.

- Advantages:

- Fewer grout lines → seamless look.

- Perfect for modern, luxurious interiors.

- Limitations: Heavier and requires skilled handling.

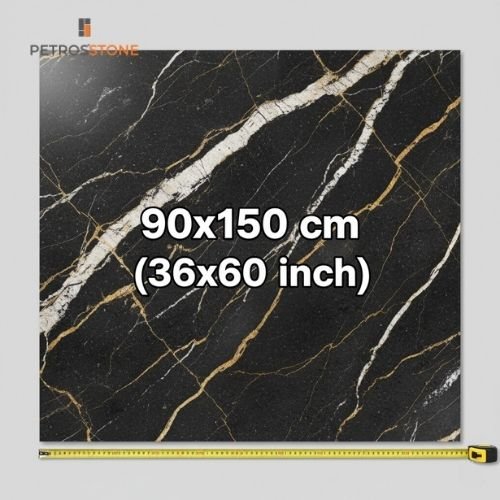

90×150 cm (36×60 inch)

- Common use: Airports, shopping malls, high-end projects.

- Advantages:

- Covers large areas quickly.

- Premium look, fewer joints.

- Limitations: Transport and installation are costly.

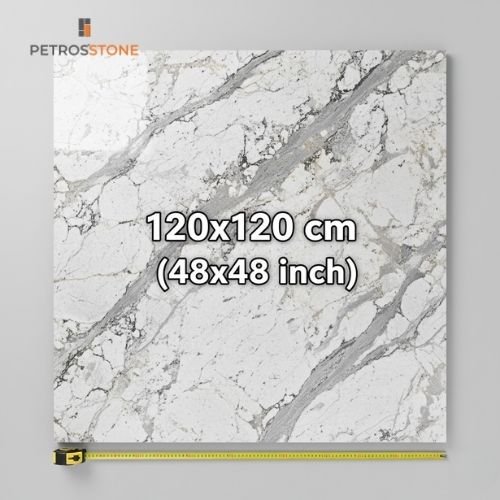

120×120 cm (48×48 inch)

- Common use: High-end flooring in malls, offices, and hotels.

- Advantages:

- Creates a bold, expansive effect.

- Very popular in luxury projects.

- Limitations: Needs advanced machinery for cutting and polishing.

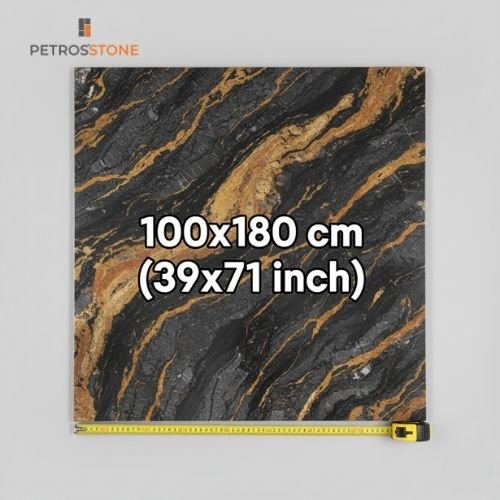

100×180 cm (39×71 inch)

- Common use: Feature walls, cladding, large lobbies.

- Advantages:

- Impressive scale for decorative applications.

- Great for minimalistic designs.

- Limitations: Very heavy, expensive, and not available everywhere.

Concept of Standard Sizes in the Stone Industry

Granite blocks are chiseled into various shapes and sizes in the stone industry. Nevertheless, it is not feasible to make each block a custom-sized project. Herein, standard sizes are developed:

- Efficiency in Production: Standard sizes permit factories to saw several tiles out of the same slab, with minimal or no waste.

- Economical to Installation: The builders and architects are certain of the exact way that the tiles will sit, hence no additional cutting has to be done on-site.

- Quality Control: Rubbing the same size will provide uniform thickness, polishing, and smooth edges.

- International Trade: Non-random dimensions facilitate the exchange of granite between nations since customers are aware of the quality expected.

Example: Granite in a slab could be 240×120 cm in size, resulting in slabs. Standard-size tiles, such as 60×60 cm or 60×120 cm, can be cut out of it with a minimum of waste compared to cutting it to some arbitrary size.

Factors Influencing Size Standards

The standard sizes of granite tiles in the market are determined by a number of factors:

- Quarry Block Size: Granite blocks are naturally large, and therefore, they cannot be made into incredibly large slabs or tiles.

- Market Demand: Depending on design trends, residential, commercial, or luxury projects might favor various sizes.

- Installation Requirements: The large tiles minimise grout lines but require more professional manpower.

- Transportation and Logistics: Tiles that are too heavy to be transported easily can be costly to ship.

- Economy in cost: Standard sizes are mass-produced with costs lessened in the manufacturing process.

- Regional Preferences: other nations have favored tile sizes according to historical and cultural fashions.

Example: Europeans use a 60x60cm tile as a flooring product, but in the Middle East, larger tiles such as 120x120cm are used in spacious spaces such as shopping malls and hotels.

Table – Summary of Common Granite Tile Sizes

| Size (cm) | Size (inches) | Best Use | Pros | Cons |

| 30×60 | 12×24 | Bathrooms, kitchens | Easy to handle, good fit for small rooms | More grout lines |

| 60×60 | 24×24 | Homes, offices | Balanced, versatile, modern look | Needs careful leveling |

| 30.5×61 | 12×24 (US) | US projects | Matches the imperial system | Limited outside the US |

| 60×120 | 24×48 | Large walls, floors | Seamless look, luxury style | Heavy, requires skill |

| 90×150 | 36×60 | Malls, airports | Covers large spaces fast | Expensive transport |

| 120×120 | 48×48 | Hotels, malls | Bold design, fewer joints | Needs special equipment |

| 100×180 | 39×71 | Feature walls | Dramatic, premium feel | Very heavy, costly |

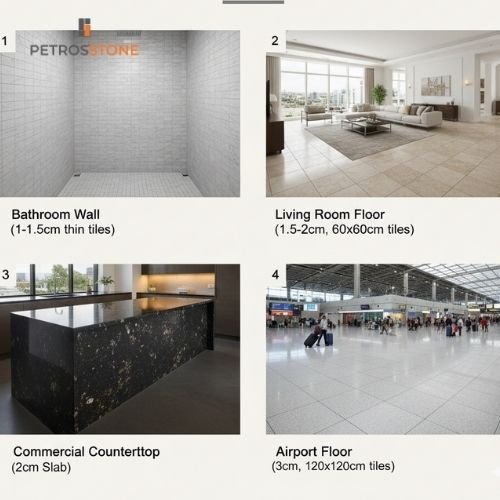

Common Granite Thickness Options

Just like size, thickness makes a big difference in how granite tiles perform.

1 cm

- Use: Wall cladding, light decorative use.

- Pros: Lightweight, easy to handle, cost-effective.

- Cons: Fragile, not suitable for floors.

1.2 cm

- Use: Budget flooring in some Asian markets.

- Pros: Affordable, widely available.

- Cons: Less strong than thicker tiles.

1.5 cm

- Use: Residential flooring, medium-duty walls.

- Pros: Good balance of strength and cost.

- Cons: Not ideal for heavy traffic areas.

1.8 cm

- Use: Office floors, mid-load areas.

- Pros: Stronger than 1.5 cm, longer lifespan.

- Cons: Slightly heavier, costs more

2 cm

- Use: Kitchen countertops, commercial flooring.

- Pros: Industry standard, strong, long-lasting.

- Cons: More expensive and heavier than thin tiles.

3 cm

- Use: Premium kitchen counters, airports, malls.

- Pros: Extremely durable, luxurious.

- Cons: Heavy, higher transport and installation costs.

Importance of Thickness in Performance

The density of granite tiles is very important when it comes to their performance in various applications. Here’s why it matters:

- Strength and Load-Bearing Capacity

- Thick tiles are tough and able to support heavy loads without breaking.

- Example: 23 cm thick tiles would suit high-workloads such as shopping malls or airports, and 1 cm tiles would suit walls or any light-weight working out area.

- Durability

- Thicker tiles are more durable because they are not easy to chip, break, or wear.

- Fine tiles can be cracked or uneven with foot traffic, and this is often experienced over time.

- Safety

- Thicker tiles minimize the chance of fracture under weight or impact, making empties secure, particularly in business or open spaces.

- Thicker tiles minimize the chance of fracture under weight or impact, making empties secure, particularly in business or open spaces.

- Installation Flexibility

- In applications, there are certain thicknesses required. For instance:

- 1-1.5 cm: Wall cladding and decoration surfaces.

- 2 cm: Residential floors and countertops.

- 3 cm: Heavy-duty flooring or custom furniture elements.

- In applications, there are certain thicknesses required. For instance:

- Aesthetic Impact

- Thicker tiles can have a sounder and more luxurious appearance. In the case of countertops, the thickness may also improve the luxurious feel of the surface.

In short, selecting the appropriate thickness will not only make your granite tiles pretty but also long-lasting, withstand the necessary weight, and be safe.

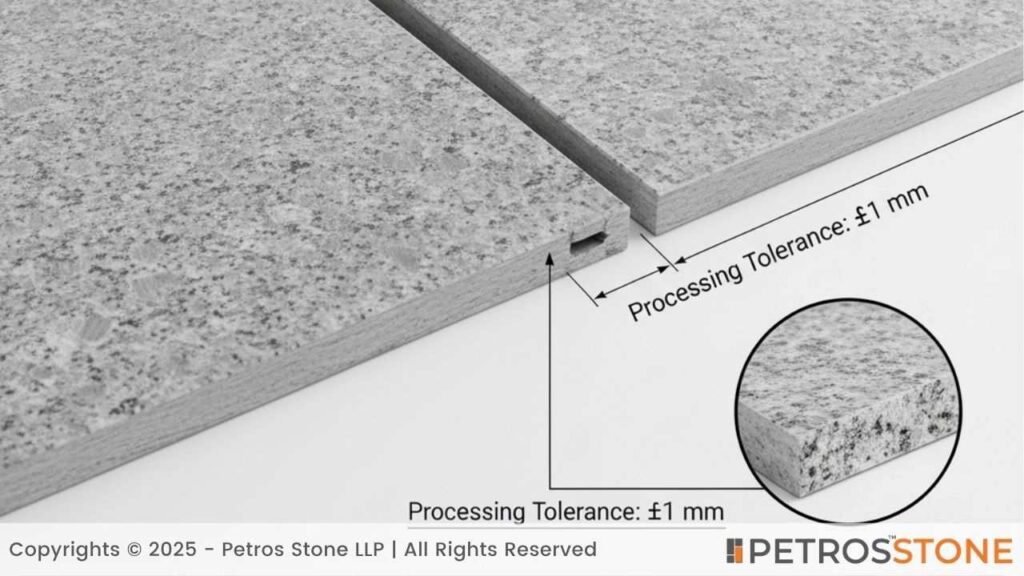

Processing Tolerance and Size Variations

Granite is a natural material and therefore, there are few variations in the size of tiles, even though it adheres to industry standards. This is referred to as processing tolerance.

- Definition

- Processing tolerance enables acceptance of variance in the size or thickness of a tile after cutting and polishing.

- Most commercial-grade granite tiles have a typical standard tolerance of ±1 mm to ±2 mm.

- Factors Affecting Size Variations

- Natural stone irregularities: Unnatural irregularities in natural stones: granite blocks are not totally consistent.

- Cutting techniques: There can be a slight deviation in manual or machine cutting.

- Polishing and finishing: Edges and surfaces can shrink by a few millimeters.

- Why It Matters

- Right tolerance makes sure that there are no gaps between tiles.

- Too much variation might result in a surface with uneven floors or wall tiling.

- When working out layouts, installers must take tolerance into consideration, particularly with large-format tiles.

- Practical Tip

- Always purchase somewhat more tiles than are required for trimming and fitting.

- With a large project or a high precision project, request tiles within the same product batch to ensure minimum variation in sizes.

Comparative Analysis of Sizes and Thicknesses

To simplify it, we shall take size and thickness in one comparison:

| Tile Size (cm) | Thickness (cm) | Ideal Use Case | Advantages | Disadvantages | Real-World Example |

| 30×60 | 1–1.5 | Bathroom walls, small spaces | – Lightweight and easy to handle- Ideal for compact areas- Cost-effective | – May not withstand heavy foot traffic- Limited aesthetic impact | Residential bathroom renovations |

| 60×60 | 1.5–2 | Living rooms, offices | – Balanced size suitable for various spaces- Provides a modern look | – Requires precise installation- May need additional support in high-traffic areas | Office lobbies and living room flooring |

| 60×120 | 2 | Commercial floors, large walls | – Creates a seamless, expansive appearance- Reduces grout lines | – Heavier and more challenging to install- Higher cost due to size and weight | Hotel lobbies and commercial hallways |

| 90×150 | 2–3 | Airports, malls, high-traffic areas | – Suitable for large-scale applications- Enhances luxury aesthetics | – Requires specialized handling and installation- Increased transportation costs | Airport terminals and luxury shopping malls |

| 120×120 | 2–3 | Premium residential and commercial spaces | – Offers a bold, contemporary look- Reduces maintenance due to fewer grout lines | – Higher material and installation costs- May require structural reinforcement | High-end retail stores and upscale residences |

| 100×180 | 3 | Feature walls, custom applications | – Provides a dramatic visual impact- Ideal for creating focal points | – Extremely heavy and difficult to handle- High cost and limited availability | Luxury hotel feature walls and custom designs |

Regional Standards and Market Demand

- North America: Prefers 12×12″, 18×18″, 24×24″. Thickness: 2–3 cm.

- Europe: Popular sizes are 60×60 and 60×120 cm. Thickness: 1.5–2 cm.

- Middle East: Larger tiles (90×150, 120×120 cm) for grand spaces. Thickness: 2–3 cm.

- Asia: 30×60 and 60×60 cm common. Thickness: 1.2–1.5 cm for affordability.

Factors Influencing Choice of Size and Thickness

- Budget: Those that are thicker and larger in size are less economical as they incur extra material and handling costs.

- Load and Usage: Thicker granite is necessary in areas of high foot traffic or furnishing to make them durable.

- Design and Aesthetics: Modern interiors are often inclined towards using large tiles to achieve a smooth, opulent appearance.

- Logistics & Handling: Oversized tiles are heavier, making the transportation, storage, and installation process more complicated.

- Availability: Suppliers or quarries do not all make very large tiles, and there is a lack of choice.

- Maintenance: The thicker tiles are more resilient and would be less frequently replaced or repaired.

- Installation Skills: Large/thick tiles require professional labor and equipment to get into position.

- Type of Surface: Surface unevenness can make smaller-sized tiles the easiest to level and to have adhesive capacity.

- Climate or Expansion: Size and thickness may influence warping or cracking in regions of varying temperatures.

- Project Timeline: An Increased number of tiles can add to the installation time requirements because of the need to do special handling or cutting.

Processing, Handling, and Installation Considerations

- Cutting: Thick or large tiles need to undergo complex cutting tools such as CNC saws or diamond wire saws.

- Handling Tiles that are more than 2 cm thick is not easy to carry, possibly necessitating lifting machinery or suctioning machines to prevent fractures.

- Installation: Professionals are required to level, apply adhesives appropriately, and have a quality surface.

- Waste Management: The larger tiles may mean increased wastage of material in recall or cutting time.

- Transportation: Large or heavy tiles require strong packing and methods of delivery to prevent cracking.

- Surface Preparation: Floors or walls shall be well leveled and cleaned to ensure that there are no uneven installations or cracking of tiles with time.

- Joint Planning: Grout lines must be spaced properly, particularly with large-format tiles, to allow them to expand and contract due to the effects of thermal changes.

- Maintenance and Sealing: Granite tiles must be sealed, particularly in the wet places, to avoid discoloration and to last longer.

- Storage on-site: To prevent warping or damage of the edges, tiles must be stored flat on a stable surface.

- Temperature Considerations: Adhesives and tile bonding can be impacted by high heat conditions during installation.

Advantages of Standardizing Sizes and Thicknesses

| Advantage | Description | Benefit for Users/Industry |

| Reduces quarry waste | Standard sizes allow maximum utilization of stone blocks | Cost-effective, less material wasted |

| Simplifies storage and packaging | Uniform tiles are easier to stack, store, and transport | Saves space, reduces handling issues |

| Faster installation | Installers can work with consistent sizes | Time-saving and efficient work |

| Easier replacement | Standard sizes are widely available for repairs or renovations | Convenience, less downtime |

| Consistent quality | Uniform thickness and dimensions ensure predictable outcomes | Professional appearance, fewer defects |

| Supports global trade | Standardization aligns with international tile markets | Easier sourcing and cross-border sales |

Custom Sizes and Thicknesses

In some cases, regular tiles are unsuitable for odd projects. For example:

- Staircases → 30×120 cm, 3 cm thick.

- Kitchen islands → 240×120 cm, 3 cm thick.

- Wall art panels → custom cuts.

These are special orders and tend to be more expensive.

Future Trends in Granite Tile Dimensions

1. Larger Tile Formats (120×120 cm and Beyond)

- Reduced grout lines, contemporary appearance.

- Common with residential and commercial use.

- Weighs more and is difficult to fix.

2. Slim Granite Panels (6–8 mm Thick with Fiberglass Backing)

- Light, quiet, and environmentally friendly.

- Suitable for walls, facades, or curves.

- Strength is enhanced by Fiberglass support.

3. Prefabricated Tiles with Polished Edges

- Ready-to-install, saves time and work.

- Ensures uniform appearance.

- Minimal customization of designs.

4. Eco-Friendly Cutting and Processing

- Water recycling and diamond wire cutting reduce waste.

- Energy-efficient equipment reduces carbon footprint.

5. Smart and Digital Technologies

- Designs are made precisely using CNC and laser cutting.

- Smart building tiles with built-in sensors.

6. Modular and Customizable Tile Systems

- Easy-to-assemble, interlocking tiles.

- Adjustable designs for different variety.

Table – Emerging Trends in Granite Tile Design and Processing

| Trend | Description | Benefits | Challenges |

| Larger Tile Formats | Tiles measuring 120×120 cm and above | Creates a seamless, modern look; reduces grout lines | Increased weight and size pose handling and installation challenges |

| Slim Granite Panels | 6–8 mm thick panels with fiberglass backing | Lightweight; suitable for curved surfaces; eco-friendly production | May require specialized installation techniques |

| Prefabricated Tiles | Tiles with pre-polished edges, ready for installation | Reduces installation time and labor costs; ensures uniformity | Limited customization options; may not suit all design preferences |

| Eco-Friendly Processing | Adoption of sustainable cutting and processing methods | Reduces environmental impact; lowers operational costs | Initial investment in new technologies may be high |

| Smart Technologies | Integration of digital fabrication and smart features into granite tiles | Enables complex designs; potential for interactive surfaces | Higher cost of production; may require specialized knowledge for installation |

| Modular Tile Systems | Tiles designed for easy customization and assembly | Simplifies installation; allows for flexible design layouts | May not be compatible with traditional tile designs; requires precise planning and execution |

Summary

There is so much variety in the size and thickness of granite tiles, but certain standards are followed worldwide.

- Sizes: 30cm by 60cm, 60cm by 60cm, and 60cm by 120cm are the most popular sizes. Bigger sizes, such as 120cm by 120cm, are also gaining popularity.

- Thicknesses: 1-3 cm (2 cm worldwide standard).

- Regional preferences: Depend on design culture and quality.

- Custom orders: Fulfill special architectural requirements.

Getting the size, thickness, and performance relationship will help you decide what granite tile fits in your project, not a fancy airport entrance, but a warm and welcoming home.

Key Takeaways

- Granite tile size and thickness directly impact aesthetics, durability, and installation ease. Popular sizes include 30×60 cm, 60×60 cm, and 60×120 cm, while thickness ranges from 1–3 cm depending on application type (walls, floors, or countertops).

- Larger tiles (like 120×120 cm and 100×180 cm) offer a seamless, modern look but require expert handling, transport planning, and structural support due to their weight and size.

- Thickness affects strength and usage suitability. Lighter 1 cm tiles work for wall cladding, while 2–3 cm tiles are ideal for high-load areas like malls, airports, or kitchen countertops.

- Standardization in sizes and thicknesses boosts cost-efficiency, installation speed, replacement ease, and global trade—benefiting manufacturers, designers, and end users alike.

- Regional preferences shape demand. For example, Europe prefers 60×60 cm tiles, North America leans toward imperial sizes (12×12″, 24×24″), while the Middle East favors large-format tiles.

- Emerging trends include slim granite panels, eco-friendly processing, digital fabrication, and modular systems—all aimed at modernizing granite tile use across residential and commercial spaces.

Feel free to get in touch for a free consultation, quote, and get a detailed understanding from our experts here at Petros®. Visit https://petrosstone.com/ or call +91-8446360361 and WhatsApp

Hello!

I’m Dr Mridali, a content writer with a background in dentistry and a passion for turning complex topics into clear, engaging stories. From healthcare to architecture, I create blogs that inform, educate, and connect with readers. With every piece, I aim to blend accuracy with creativity to make information truly valuable.

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite