We will focus on the 10 best granite tile (including slab/tile/natural stone) manufacturers in India in this article, including real data, machinery, known real projects, contact information, and expertise of their work.

Granite is a very beautiful natural stone that is very tough. They are applied to the floors, walls, countertops, exteriors, interiors, etc. In India, the production of granite tiles is a large business. The Indian manufacturers not only supply but also export their products to numerous countries.

Tiles are cut, polished, finished, packed, and delivered. The purchase of the appropriate granite tile necessitates an appreciation of quality, uniformity, finish, cost, supply capability, and sustainable practices, among others.

Here is a list of 10 Best Granite Tile Manufacturers in India:

- Petros® Stone LLP

- Pokarna Granites

- Classic Marble Company (CMC)

- Oswal Granites & Tiles

- Zingin LLP

- Jain Marble Centre (JMC)

- Rashi Granite Exports

- Aro Granite Industries Ltd.

- Aditya Stonex

- Glittek Granites

Best Granite Tile Manufacturers in India

The following are the top ten manufacturers or processors of granite (tiles/slabs/natural stone) in India.

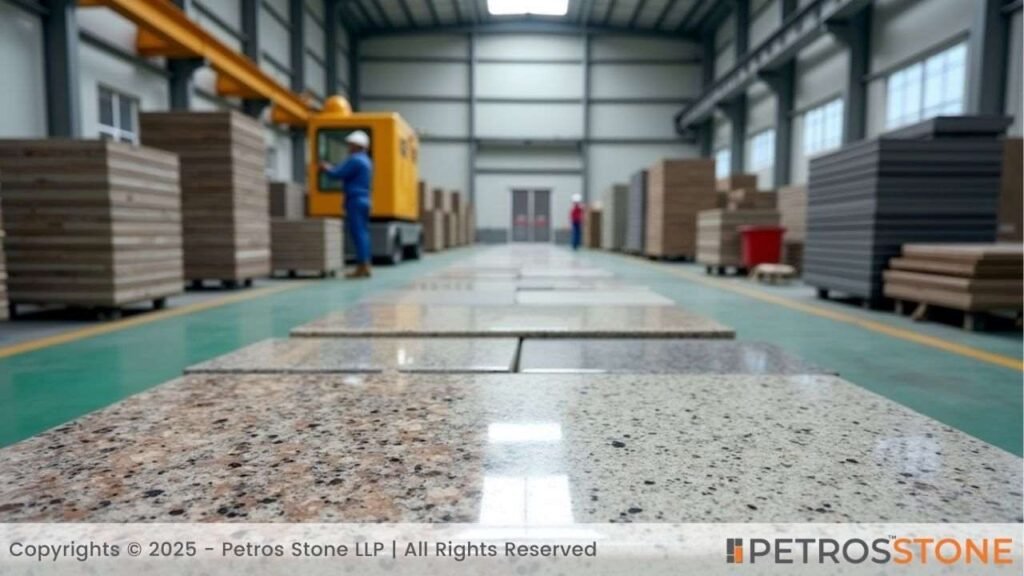

1. Petros Stone LLP – Pune, Maharashtra

Overview

Petros Stone LLP is a large manufacturer and exporter of natural stones: granite, marble, quartz, and porcelain. They operate out of Pune. They have established a good image of a variety of stones, custom sizes, good finish, and exports.

Info

- Location: Pune, Maharashtra

- Address: Undri, Handewadi Road area, Kanade Nagar, Pune

- Contact: Phone +91-8446360361 (customer contact/sales)

Machinery / Infrastructure

- They use multicutters, line polishing machines, and edge profiling.

- They use quality in terms of calibration, polishing, and finishing.

- Their product inventory is huge (100+ natural granites) and is manufactured using modern technology.

- They deal with export packing and quality control to match the export standards.

Expertise

- Granite, slabs, marble, engineered stone.

- Custom sizes, finishes (polished, perhaps honed, etc.).

- Meet export standards; competent in providing bulk orders.

- Nice colouring effects, design.

Projects / Real-Clients

- They have shipped the products to numerous countries; they give export destinations and clients, but project names are less visible.

- The testimonials of some customers: consumers in the USA, Russia, Egypt, and so on have utilized their granite/quartz slabs. (i.e., a client of the USA had reported high-quality quartz slabs; another client of Egypt had ordered granites such as Galaxy Black, Shiva Gold, etc.)

- They provide flooring and cladding stone, countertops, etc, for residential and commercial projects (specifically Interior) in India through architects ordering them to do interior works.

Reviews

- Customers commend the richness of colour, finish quality, and the ability to make custom sizes.

- Quality polishing, accuracy, thickness, and variety are often positive remarks.

- There is a mention of good service in the sample delivery and exporting processes.

2. Pokarna Granites – Hyderabad / Telangana

Overview

Pokarna is a giant in natural and engineered stone. They are producing engineered stones/quartz surfaces besides granite. They have a state-of-the-art production plant in Telangana, which keeps on extending.

Info

- Telangana facility at Mekaguda, near Hyderabad.

- They are currently planning to grow the plant; they deal with engineered stone, quartz surfaces, etc, in addition to natural stone activities.

Machinery / Infrastructure

- They also utilize Bretonstone technology (Italian) in quartz/engineered surfaces.

- They are large in size: the latest growth is an investment of Rs 440 crores in capacity with a third line of Bretonstone.

- Build area and throughput are also essential, with automation and up-to-date lines.

Expertise

- Good in engineered quartz stone surfaces brand: Quantra; also in natural stone works.

- Good, large, quality volume, big order pickup of interior surfaces, countertops, etc.

- Focus on sustainability and innovative technology.

Projects / Real Clients

- They have opened a large quartz surface plant (built area around 6,00,000 sq ft, very big plant).

- Their quartz surfaces are utilized by a large number of commercial customers; lobby floors, retail counter tops, etc.

- Not always specific named projects published, but known in the industry for supplying major hospitality and commercial interior firms.

Reviews

- Positive, generally, regarding product innovation and capacity.

- Their growth is an indicator of confidence in the market and investors.

3. Classic Marble Company (CMC) – Mumbai / Silvassa

Overview

Classic Marble Company is based in Mumbai and has a huge factory/showroom at Silvassa. They bring natural stones, process composite/engineered stones, and have a very broad choice of marble, onyx, travertine, etc. They have the brand KalingaStone. They possess an extensive range of pre-emerged and domesticated minerals.

Info

- Headquartered in Mumbai.

- Showrooms in Mumbai, Silvassa, etc.

- Large stockyards along with a factory in Silvassa.

Machinery / Infrastructure

- They have a big factory in Silvassa; they process large quantities of stone.

- They do large volume polishing, large finishes.

- Modern polishing and finishing lines.

Expertise

- Especially well-endowed in marble and engineered stone, though it does have natural/exotic stones featuring many granites.

- Niche collections (e.g., “9th Avenue”) of rare stones.

- They target high-end interior design, imported stone, and so on.

Projects / Real Clients

- CMC has carried out a lot of luxury residential tower projects in Mumbai, Bengaluru, and Delhi NCR, with their 9th Avenue line being used in the lobby, lift cladding, interiors, and staircases.

- They supply imported stone and marble to luxury hotel and resort chains.

- They are employed in high-profile commercial facilities, showrooms, and corporate facilities.

Reviews

- Complimented on variety, finish, and luxury feel.

- There are clients who mention a high price but worth it in exclusivity and stone quality.

4. Oswal Granites & Tiles – Coimbatore / Pune & other locations

Overview

Oswal Granites & Tiles is a supplier/processor of stone business formed in Coimbatore around 2007 with the aim of marketing black granite as such; then expanded to include a range of colour granites and tile offerings as well. They also operate in Pune, etc.

Info

- Head offices: Coimbatore, plus showrooms and supply in Pune.

- They have offices/showrooms, and they export their products to numerous countries.

Machinery / Infrastructure

- They have cutting, polishing, and finishing tools.

- On some products, hand cutting/machining.

- Good procurement network of quarry owners and stockists; this facilitates the availability of raw blocks.

Expertise

- Finishes granite tiles, flamed, honed, and polished.

- Extremely diverse: black, red, white granites, etc.

- Exporting quality stones, with the capability to deliver in bulk.

Projects / Real Clients

- No particular grand-sized identified building project is ever mentioned publicly, but their granite is utilized in numerous domestic/trade interiors and outward look in Coimbatore, Pune, and additional cities of South/West India. Designers put their tiles on flooring, facades, paving driveways, etc.

- The clients have rated them with respect to the supply of office interiors and house flooring.

Reviews

- Clients appreciate their diversity, completion choices, and sensible prices.

- There are some report delays or batch variations in stone batches (natural variation), but the feedback is satisfactory.

5. Zingin LLP – Pune, Maharashtra

Overview

Zingin LLP is located in Pune, Maharashtra. The firm sells granite tiles and slabs to various foreign markets. Their focus is on quality adjustment, cutting accuracy, and design-global appeal.

Info

- Headquartered in Pune, Maharashtra.

- Good export markets (Europe and the Middle East).

- Processing units and operational warehouses in Pune, Maharashtra.

Machinery / Infrastructure

- Contemporary calibration lines and automatic polishing machines.

- Extremist finishing facilities meet uniform export standards.

- Ability to do tailor-made sizes and textures.

Expertise

- A premium granite tile and slab player.

- Serving commercial and residential building markets overseas.

- International customers are known to turn in a slightly shorter quay due to their flexibility.

Projects / Real Clients

- Granite is used in commercial malls within the UAE.

- Residential luxury developments in Europe.

- Regular supplier of mid-sized real estate developers in Gujarat.

Reviews

- Cited to be flexible, cut sharp, and on time.

- Clients like the fact that they can fit into international specifications.

6. Jain Marble Centre (JMC) – NCR Delhi

Overview

JMC is based in Delhi and has been serving the high-end stone needs of North India. They have a reputation for possessing a broad array of granite and marble tiles, which cater to architects, interior designers, and homeowners.

Info

- Headquartered in New Delhi.

- Well-networked distribution in NCR Delhi.

- Access to showrooms for residential buyers and contractors.

Machinery / Infrastructure

- Machines are used in the polishing and finishing of granite and marble tiles.

- High stock-handling capacity.

- Concentrate on diversity instead of mass exports.

Expertise

- Flooring, wall cladding, kitchen, and staircase granite tiles.

- Well-established markets in the Delhi NCR that have steady household demand.

Projects / Real Clients

- Providing granite to the luxury hotels in Gurgaon.

- Supplies flooring and granite to residential societies in Delhi NCR.

- Cooperated with retail showroom fit-outs in Delhi.

Reviews

- Clients appreciate their diversity and affordable price bracket.

- Others emphasize custom service and design.

7. Rashi Granite Exports – Bangalore

Overview

Rashi, with its base in Bangalore, has established a good brand image as a high-quality granite producer. Their specialty is exotic granite found in Indian quarries and has an international peak of processing.

Info

- Head Office: Bangalore, Karnataka.

- Distribution: Excellent worldwide coverage, especially in the USA, Europe, and the Middle East.

- Factories located near quarry belts in Karnataka.

Machinery / Infrastructure

- World-class block cutters, cutting lines, and CNC cutting units.

- Multi-wire saw and water-jet saw.

- Computerized resin and finishing lines where longevity is required.

Expertise

- Famous for the exotic types of granite with unusual colors and designs.

- Good exporter of residential, hotel, and airport buildings globally.

- Premium market positioning.

Projects / Real Clients

- Granite is used in airport construction in the USA.

- Five-star hotel chains in Europe and the Middle East.

- Houses and exclusive commercial buildings.

Reviews

- Saluted as a perfect color range and professional export.

- Popular amongst architects in high-quality projects.

8. Aro Granite Industries Ltd. – Hosur, Tamil Nadu

Overview

Aro Granite is a company based in Hosur, Tamil Nadu, which is the exporter of tiles, slabs, and cut-to-size granite products to more than 50 countries..

Info

- Corporate office and plant in Hosur, Tamil Nadu.

- Publicly listed, which is highly export-driven.

- International customers in Europe, the USA, and the Middle East.

Machinery / Infrastructure

- Multi-wire saws, automatic polishing lines.

- High-tech resin lines and computerized cutting.

- High volume to meet large world orders.

Expertise

- Specializes in the large-scale and regular supply of granites.

- Good quality assurance system in line with international standards.

- Exports calibrated granite tiles and slabs.

Projects / Real Clients

- Granite is used in metro stations in Europe.

- Middle East airport projects.

- Indian government and institutional projects.

Reviews

- Recognized as one of the most trusted exports.

- Admired because of its stability and professional functioning.

9. Aditya Stonex – Udaipur, Rajasthan

Aditya Stonex is a renowned granite and marble manufacturer that is located in the state of Rajasthan with special emphasis on Udaipur Black and other local types.

Overview

Aditya Stonex is a company that processes and exports granite, marble, and natural stone to its local and international customers, headquartered in Udaipur.

Info

- Factory and office in Udaipur, Rajasthan.

- Export to the Middle East and Europe.

- Expert local presence in Indian prime housing projects.

Machinery / Infrastructure

- State-of-the-art gangsaws, polisher facilities, and calibers.

- Effective management of block cutting and finishing.

Expertise

- Particularly known for Udaipur Black Granite.

- Large product range of marble and sandstone.

- Capacity to provide customized finishes.

Projects / Real Clients

- Hotel and luxury villas in Rajasthan.

- Granite that is harmonized and exported to projects in the UAE, such as resorts.

- Real estate developers in North India.

Reviews

- Customers appreciate quality and local skills.

- Thought to be trustworthy and professional in service.

10. Glittek Granites – Bangalore

Overview

Based in Bangalore, Glittek Granites is an Indian granite processing and exporter that distributes flooring and cladding materials to international clients.

Info

- Corporate office in Bangalore, Karnataka.

- Export business in Europe, the USA, and Australia.

Machinery / Infrastructure

- Equipped with automated resin lines, polishing units, and CNC cutting machines.

- It has the ability to process various finishes such as honed, polished, and leathered.

Expertise

- Unwavering emphasis on granite tiles and slabs as construction materials.

- Experts in the exportation of uniform high-durability stones.

Projects / Real Clients

- Providers of granite to office complexes in the USA.

- European residential apartments.

- Indian luxury retail stores and malls.

Reviews

- Complimented on the quality of polish and durability.

- Clients emphasize their importance, dependability, and delivery times.

Comparative Table of Top Granite Tile Manufacturers

| Manufacturer | Location | Machinery / Infrastructure | Expertise | Major Projects / Clients | Reviews |

| Petros Stone LLP | Pune, Maharashtra | Advanced CNC cutting, polishing units, calibration lines | Customized granite tiles, modern textures, strong design focus | Luxury residences in Pune & Mumbai, commercial interiors in Maharashtra | Praised for design innovation and finish quality |

| Oswal Granite | Coimbatore / Pune | Gangsaw machines, polishing & resin lines | Traditional granite tiles and slabs, export-oriented | Residential townships in Rajasthan, export clients in Middle East | Known for reliability and large-scale capacity |

| Zingin LLP | Pune, Maharashtra | Calibration lines, automatic polishing machines | Premium granite tiles, export customization | Commercial malls in UAE, residential projects in Europe | Appreciated for flexibility and timely shipments |

| Jain Marble Centre (JMC) | Delhi NCR | Polishing & finishing machines, large stockyards | Granite for flooring, wall cladding, kitchens | Hotels in Gurgaon, residential societies in Delhi NCR | Valued for variety, affordability, and service |

| Pokarna Granites | Hyderabad, Telangana | Multi-wire saws, Italian polishing lines, resin plants | Exotic granite, premium slabs, export-grade | Airports in USA, premium hotels worldwide | Highly trusted for international-grade quality |

| Classic Marble Company (CMC) | Mumbai & Silvassa | Large processing units, automated polishing lines | Luxury natural stone & engineered stone, exclusive imports | Residential towers in Mumbai & Delhi NCR, 5-star hotels | Known for exclusivity, premium pricing, wide variety |

| Rashi Granite Exports | Bangalore, Karnataka | CNC cutting, water-jet systems, automated polishing | Exotic granite varieties, strong export base | International airports, luxury villas, hotels in Europe | Renowned for global reach & premium selection |

| Aro Granite Industries Ltd | Hosur, Tamil Nadu | Multi-wire saws, polishing & resin lines, computerized cutting | Large-scale calibrated granite tile exports | Metro stations in Europe, airports in Middle East | Reliable exporter, consistent quality |

| Aditya Stonex | Udaipur, Rajasthan | Gangsaws, calibration lines, polishing units | Udaipur Black Granite, marble & sandstone | Villas & resorts in Rajasthan, exports to UAE | Praised for professionalism & consistent quality |

| Glittek Granites | Bangalore, Karnataka | Automated resin lines, CNC machines, polishing units | Granite tiles for flooring, cladding, countertops | Office complexes in USA, malls in India, housing in Europe | Appreciated for durability & export reliability |

Industry Challenges and Manufacturer Responses

Manufacturing of granite tiles in India has a number of challenges. These are the key ones and the performance of leading manufacturers.

1. Market Competition and Best Practices

Challenges

- Great domestic and import competition (other stone, engineered stone).

- Low pricing at the expense of quality.

- Buyers are expecting customized sizes and finishes.

Responses

- The major producers invest in superior machines to cut down on wastage and enhance yield.

- Focus on product differentiation, exotic colours, special finishes, and custom design.

- Good branding, export licenses (ISO, etc.), and showrooms to access architects/designers.

2. Green Technology and Responsible Sourcing

Challenges

- Quarrying has environmental effects: deforestation, dust, and water consumption.

- Landfills are caused by waste stone rejects.

- Cutting/polishing high energy use; finishing chemicals are potentially pollutants.

Responses

- An increasing number of companies are shifting towards water recycling units in their factories.

- Energy-efficient machinery; more efficient planning to lessen waste.

- Others are beginning to receive environmental certifications; increased disclosure on quarry source.

- Use less toxic chemicals, and use natural finishing methods.

3. Supply Chain and Logistics Issues

Challenges

- Moving heavy stone out of quarries to plants, finished goods to customers, or exporters. Sometimes, there is poor infrastructure (roads, ports).

- Changes in the availability or quality of raw materials (blocks).

- Habits, export laws, and delays to export customers.

Responses

- Manufacturers who place their plants near the quarries or enhance their internal logistics.

- Forming strategic alliances with logistics/transport firms.

- Good quality raw blocks; improved quality at the source.

- Considering export markets with superior legal/regulatory clarity.

4. Product Consistency and Global Standards

Challenges

- Ensuring even colour, grain, and finish between batches. By nature, natural stone is variable; clients desire uniformity.

- Exporting to international standards (Polish, thickness, water absorption, slip resistance, etc.).

Responses

- Tight quality control procedures; sample analysis; laboratory analysis of rocks.

- Modern polishing/calibration machine; cutting precision.

- Trade show participation to maintain best practices.

Granite Tile Applications – Trends & Real-World Projects

The usage of granite tiles is broad. The following are typical applications and real-world trends.

Residential Use Cases

- Kitchen counter tops: Granite has become very popular as it has not been affected by scratches, heat, etc.

- Flooring: Entrance halls, living rooms; polished or honed finish.

- Wall cladding/feature walls: Accent walls of exotic colour.

- Outdoor decks/patios: Rough non-slip granite.

- Bathrooms: Vanity tops, shower walls, and flooring; needs quality polish and sealing.

Commercial Use Cases

- Hotels/resorts: Lobby floors, facades, staircases, walls; exotic granites, big slabs.

- Office buildings/malls: Cladding, flooring, reception.

- Public infrastructure: Airports, railway stations – high traffic, large-sized tiles/slabs.

- Monuments/memorials: Aesthetic stones of permanence.

Case Studies & Design Inspirations

While specific case studies are sometimes proprietary and less publicly documented, a few While specific case studies are sometimes proprietary and less publicly documented, a few common patterns:

- Luxury interiors with the use of large slabs (reduction of grout lines) provide a clean, premium appearance.

- Focal points (countertops, wall panels, etc.) made of veined or patterned granites are contrasted with plain floor tiles.

- Composite material design: the mix of granite, wood, metal, glass, etc.

- Finishes: Polished, honed, brushed, flamed (outdoors). Trends are moving slightly towards more natural or textured finishes instead of being ultra-glossy

How to Choose the Right Granite Tile Manufacturer

As a buyer (developer, architect, or homeowner), it is important to select the appropriate As a buyer (developer, architect, or homeowner), it is important to select the appropriate manufacturer. The following are tips, pitfalls, and a checklist.

Expert Tips

- Inspect Samples: Request actual tile/slab samples, not photos. Look at color, veining, and finish.

- Check Thickness and Calibration: Tiles must be of equal thickness; edges must be straight. Dissimilarity brings trouble in the future.

- Polish and Finish Quality: polish must be even, smooth, and resistant to water and stains.

- Certifications and Compliance: ISO, environmental clearance, export certification, etc, particularly when importing or performing premium work.

- After Sales / Service / Warranty: Do they seal, maintain a consistent supply, replacements, etc.

- Delivery/Logistics: Heavy rocks; any delay or fragility during transportation will ruin value. Good packaging and transport.

- Cost vs Value: cheapest is not always the best; look at the lifetime, maintenance, and look.

Common Mistakes

- Making a decision based on price with no quality inspections.

- Failing to consider the toxin variation (assuming the same batches).

- Not paying attention to the suitability of the finish: e.g., using a glossy stone outside, making it slippery.

- The cost of installation (cutting, leveling, grouting) is underestimated.

Buyer Checklist

| Item | Yes / No |

| Sample inspected in person | |

| Thickness & size consistency guaranteed | |

| Finish (polished / textured / matte) appropriate for use | |

| Certificates (quality / environmental / export) present | |

| Clear terms on delivery & packaging | |

| Warranty / replacement policy | |

| Supplier has reference projects / reviews | |

| Price includes all extras (sealing, packaging, transport) |

Future Directions in Indian Granite Tile Manufacturing

In the future, certain trends, upheavals, and global roles are likely to occur.

Upcoming Trends

- Exotic, rare stones: Unique requests will also grow in ostentatious colours, unique granites, and tailor-made cuts.

- Textured and natural finishes: Duller finishes that are rustic or honed.

- Hybrid products: Natural stone with engineered material; Stones with added features (LED lighting, inlays).

- Sustainability: Increased customer demands for green, fair labour practices, as well as environmental responsibility.

Technological Disruptions

- Automation/robots: To cut, finish, polish; eliminate human error and raise precision.

- Digital stone printing / CAD/CAM: cuts and shapes stone accurately, incorporating it in computerized designs.

- 3D scanning/mapping: To match veins/patterns between slabs; also to minimize waste through improved planning.

Global Market Role

- India is endowed with extensive granite reserves, labour, and the cost plus the quality make it competitive.

- Expanding exports, particularly to the Middle East, Europe, the USA, and East Asia.

- Should uphold steady quality, certifications, and punctual delivery to be in a position to compete internationally.

Quotes & Reviews

Petros Stone LLP

Summary

The Indian granite tile machining industry is robust, and numerous players in the industry provide high-quality, variety, and value. More prominent/reputable firms include Petros Stone LLP, Oswal Granites & Tiles, Zingin LLP, and Pokarna Granites, which have good infrastructure and the ability to export.

On the buyer side, it takes success in selecting manufacturers with a known history of success, good finish, steady supply, correct certifications, and knowledge of the specific application (indoors/outdoors, commercial/residential).

In the future, the industry can be expected to experience increased focus on sustainability, exotic and custom stones, digitalization and automation during the manufacturing process, and closer connections to the international markets.

Feel free to get in touch for a free consultation, quote, and get a detailed understanding from our experts here at Petros®. Visit https://petrosstone.com/ or call +91-8446360361 and WhatsApp

Hello!

I’m Dr Mridali, a content writer with a background in dentistry and a passion for turning complex topics into clear, engaging stories. From healthcare to architecture, I create blogs that inform, educate, and connect with readers. With every piece, I aim to blend accuracy with creativity to make information truly valuable.

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite