At Petros® Stone LLP, every export project is more than just the movement of goods — it’s a story of collaboration, precision, and commitment to excellence. Our recent export of gangsaw granite to Poland stands as a testament to how attention to detail and a client-focused approach can turn a business transaction into a long-term partnership.

This journey started with an experienced customer — a seasoned investor in both real estate and stone companies — whose knowledge of material quality and sourcing processes meant that we had to meet the highest benchmarks. This was not just an order; it was a challenge to deliver perfection.

- Client Profile: An Experienced Eye for Quality

- Block Inspection: Setting the Foundation for Perfection

- Gangsaw Slab Cutting & Inspection

- Material Selection & Confirmation

- Production & Finishing: Where Craft Meets Technology

- Packaging & Loading: Securing the Investment

- Shipping to Poland via Rijeka

- Commitment Beyond the Transaction

- Client’s Feedback

- Conclusion – A Partnership Built on Stone and Trust

- Ready to Import Premium Granite?

Client Profile: An Experienced Eye for Quality

The client was no stranger to the intricacies of the stone industry. As someone who invests in both real estate development and stone businesses, they understood exactly what they wanted and what it took to get it. They were focused on sourcing gangsaw granite slabs of exceptional quality for use in high-end construction projects in Poland.

Their expectations were clear:

- Complete transparency in every stage of production and shipping

- Consistent color and texture

- High yield from selected blocks

- Precision in cutting and finishing

- Packaging that ensures safe delivery

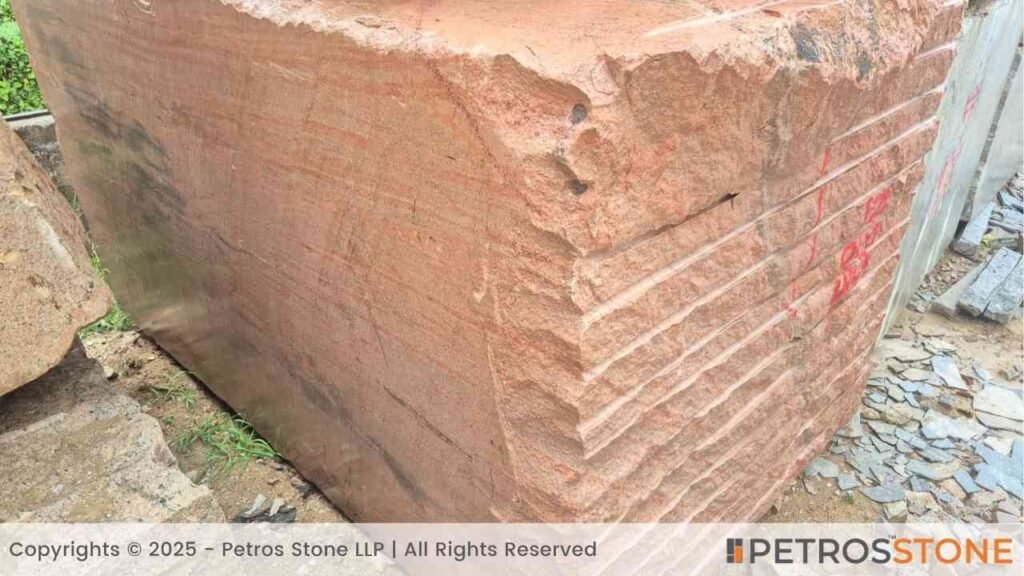

Block Inspection: Setting the Foundation for Perfection

The process began at our granite yard, where an extensive range of raw granite blocks awaited selection.

Since the client was overseas, high-resolution videos and detailed images were sent for their initial review. These visuals captured:

- Block dimensions

- Texture and natural grain flow

- Color uniformity

- Potential yield once gangsaw

This step was crucial. Gangsaw slabs are only as good as the blocks they come from, so ensuring that the raw material was flawless set the tone for the entire project.

The customer, with their trained eye, immediately identified the blocks that matched their aesthetic and structural requirements.

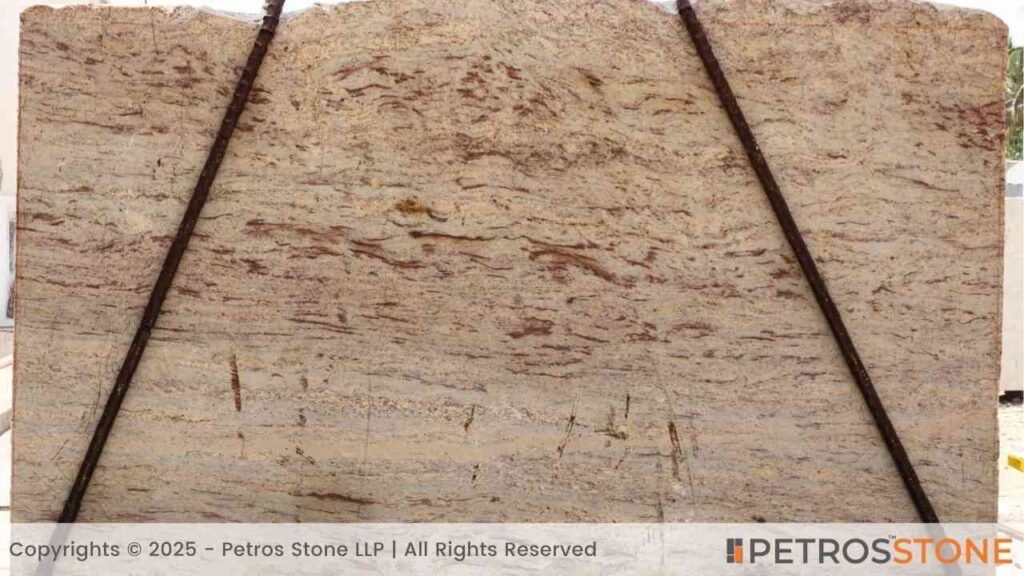

Gangsaw Slab Cutting & Inspection

Once the blocks were finalized, we moved into gangsaw cutting. This process transforms large raw blocks into perfectly parallel slabs with a consistent thickness.

When the slabs were ready, we conducted a comprehensive inspection, recording videos and close-up photographs. This allowed the client to evaluate:

- Surface texture – ensuring smoothness and evenness

- Veining patterns – whether subtle or dramatic, depending on their project needs

- Gangsaw finish quality – free of defects or surface inconsistencies

The client reviewed the materials remotely and provided valuable feedback, confirming that the slabs matched their requirements.

Material Selection & Confirmation

Based on the inspections and continued discussions, the client finalized their slab selection. This included:

- Specific material types

- Exact quantities

- Any special requirements for dimensions or surface finish

This confirmation allowed our production team to plan the finishing processes with precision.

Production & Finishing: Where Craft Meets Technology

After slab selection, we moved into production and finishing. This involved:

- Calibration for uniform thickness

- Edge trimming for perfect dimensions

- Polishing to achieve a refined, high-gloss finish

- Final quality control to ensure every slab met international export standards

Our state-of-the-art machinery combined with skilled craftsmanship ensured that each slab was identical in quality and appearance, ready for premium installation in Poland’s construction projects.

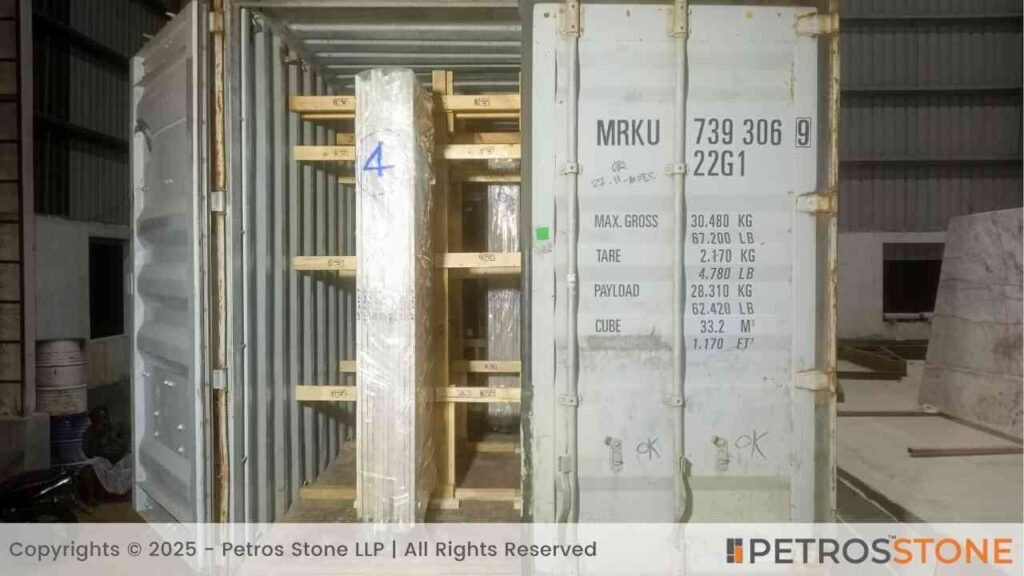

Packaging & Loading: Securing the Investment

The importance of packaging in stone export cannot be overstated. Granite is strong, but mishandling or poor packaging can lead to costly damages.

For this shipment:

- Each slab was packed in reinforced wooden A-frames

- Protective foam layers and spacers were used to prevent contact damage

- Crates were clearly labeled with material details, slab counts, and handling instructions

The final packaging allowed for safe handling during loading and unloading, ensuring the slabs would arrive in Poland exactly as they left our facility.

Shipping to Poland via Rijeka

The packaged slabs were loaded into containers in a carefully planned sequence for safe transit. The shipment was dispatched through the Port of Rijeka, a strategic choice for efficient delivery to Poland.

We also managed:

- Complete export documentation

- Packing lists for customs clearance

- Tracking details for real-time shipment monitoring

The client was kept informed at every stage — from container sealing to port arrival.

Commitment Beyond the Transaction

For Petros® Stone LLP, this project wasn’t just about delivering granite — it was about delivering confidence. Our focus on clear communication, uncompromising quality, and on-time delivery reinforced the trust our client placed in us.

Client’s Feedback

The client acknowledged:

- Top-notch material quality and slab consistency

- Excellent budget alignment and creative use of supplementary materials

- Professional communication throughout the entire journey

Their team also expressed strong interest in sourcing future marble and quartz slabs from Petros® Stone LLP for other large-scale villa and resort developments in Poland.

Conclusion – A Partnership Built on Stone and Trust

The successful export of gangsaw granite to Poland is a shining example of what happens when expertise, technology, and customer-centric service come together.

From block selection to final delivery, every detail was executed to perfection — ensuring that our granite will play a key role in creating timeless architecture in Poland.

Ready to Import Premium Granite?

If you’re looking for world-class granite, marble, quartz, or engineered stones, Petros® Stone LLP is your trusted partner.

WhatsApp Us Now for quick inquiries and quotations.

Or fill out our Contact Form to get started with your project today.

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite