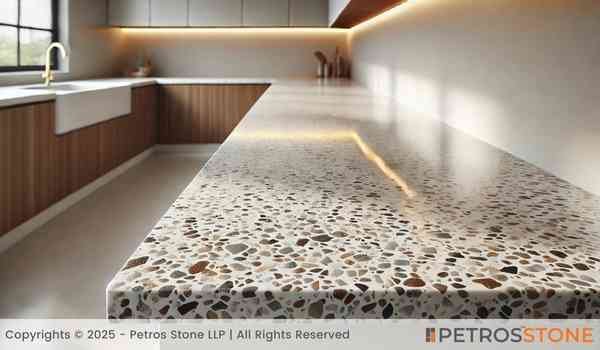

Sintered stone is quickly becoming the most popular stone kitchen surface in Australia. It takes the aesthetic elegance of a natural stone, e.g., marble or granite, but it is more durable, stain-free, and has low maintenance. Unlike the traditional natural stones, it does not require sealing, is highly scratch-proof, heat-resistant and non-porous; there is no need to be afraid of smells or bacteria finding their way in through the tiny pores.

Moreover, with quartz now restricted in many Australian states due to silica dust health concerns, homeowners and designers are turning to sintered stone for a safer, high-performance alternative. For a standard-sized kitchen, the average total installed cost of sintered stone countertops is around AUD $5,000–$6,000.

In this article, we will help you understand the real cost of sintered stone countertops in Australia, break down each element of pricing, and even include a step-by-step calculator to estimate your own cost based on your kitchen layout. You’ll also find tips on how to save money without compromising quality.

Table Of Contents

- What is Sintered Stone?

- Comparison with Other Countertop Materials

- Cost of Sintered Stone Slabs in Australia

- Installation Costs for a Standard Kitchen

- Logistics, Cutting, and Finishing Costs

- Full Countertop Cost: A Real Example

- How to Calculate the Cost of Your Countertop (Step-by-Step Guide)

- Step-by-Step Process

- Sample Plug-&-Play Calculator Table

- Tips to Save Money Without Compromising Quality

- Where to Buy Sintered Stone Countertops in Australia

- Wastage Management and Smart Use of Leftovers

- FAQs

- Summary

- Key Takeaways

What is Sintered Stone?

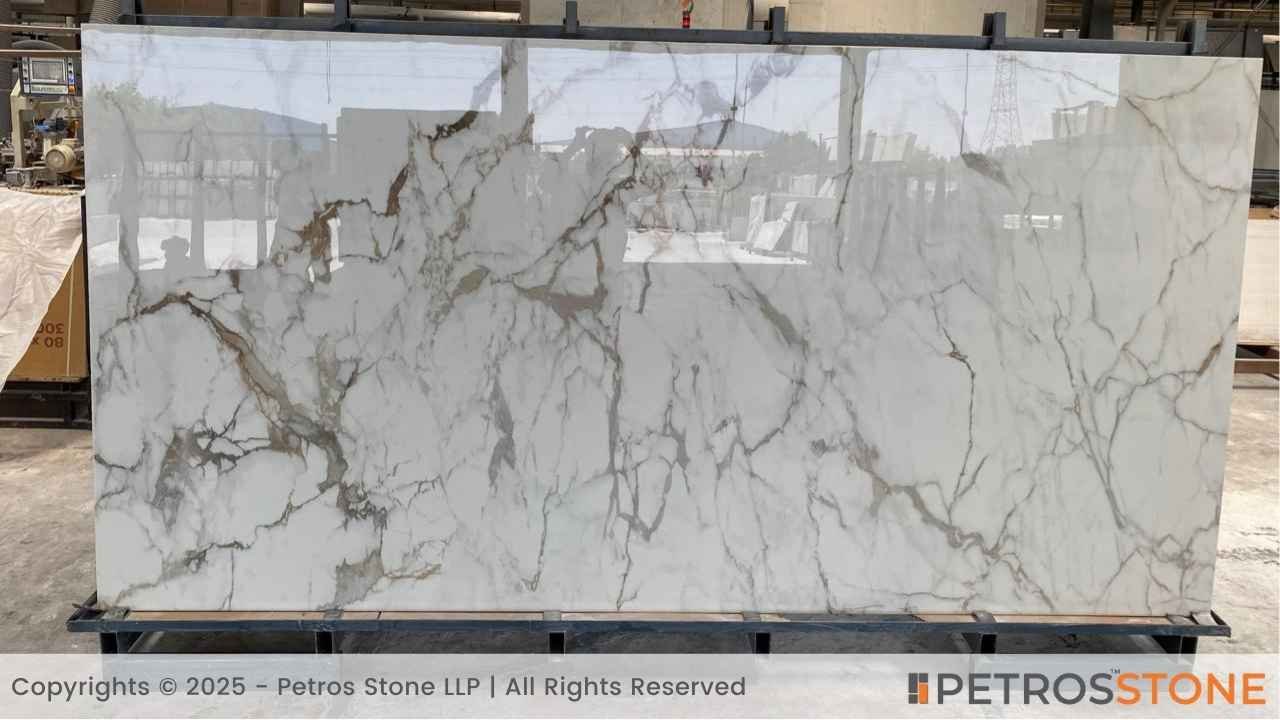

Sintered stone is an artificial stone, created by combining natural minerals, e.g. quartz, porcelain and metal oxides and subjecting them to manufacturing conditions at high pressure and high temperatures. The outcome is a very dense, exceptionally hard, almost impervious to heat, scratching, UV exposure and stain slab.

It can also look like marble, granite, concrete, or porcelain tile, which makes it very versatile in terms of design.

In no particular order, the following are the key brands of sintered stone in Australia:

- Petros Stone – specialises in designer sintered stone slabs with unique textures and hues, combining aesthetics and long-term performance.

- Neolith – comes in both thin 6 mm and thick 12-20 mm panels

- Dekton – has very durable 12-20mm slabs in large format options

- Laminam – Porcelain 6-12mm thick slabs

- Maximum – a new brand that provides premium finishes of about 12 mm

Comparison with Other Countertop Materials

| Material | Approx. Price per m² (AUD) (Material cost at factory) | Durability | Maintenance Required |

| Granite | $40 – $80 | Durable, heat-tolerant | Requires sealing, moderate upkeep |

| Marble | $45– $95 | Elegant, softer | Needs sealing, careful cleaning |

| Quartz | $45– $135 | Strong, low-maintenance | Wipe clean, no sealing |

| Sintered Stone (Neolith, Dekton, Laminam, Maximum, Petros Stone) | $50 – $120+ | Very strong, non-porous | Nearly no maintenance, no sealing |

Although sintered stone is usually more expensive initially than quartz or certain granites, its durability and need to do very little maintenance often make it more cost-efficient in the long run. For more details, refer to this article.

Cost of Sintered Stone Slabs in Australia

Material Pricing: By Brand and Thickness

In Australia (mid-2025), prices usually fall under the following ranges, depending on thickness and finish:

| Brand | Thickness Options | Typical Price Range per m² (AUD) |

| Neolith | 6 mm | $350 – $500 |

| Neolith | 12–20 mm | $500 – $700 |

| Dekton | 12 mm | $450 – $650 |

| Dekton | 20 mm | $650 – $850 |

| Laminam | 6–12 mm | $400 – $600 |

| Maximum | 12 mm | $370 – $550 |

| Petros Stone | 15 mm | $150 |

This price can be relative to the supplier, location, slab availability or special finish.

Impact of Colour and Finish

- These basic solid colours (e.g. plain white, grey) tend to be in the lower end of the price list.

- Natural-look patterns, such as a marble pattern of veins, a concrete effect, or a wood pattern, can be more expensive (10-20%).

- Matte may face a 1015 per cent premium on gloss or polished finishes.

Benefits and Costs of Large Format Slabs

- Big format slabs may be 3 m x 1.5 m or even larger, which minimises the seams and residues and appears seamless.

- They usually command higher prices per slab, such as an extra $100–$200 a slab, due to special handling or rarity.

- However, fewer slabs can decrease the number of fabrication joints and man-hours and wastages, so the net cost per m² can be competitive.

Installation Costs for a Standard Kitchen

Defining a “Standard Kitchen” in Australia

Typically:

- One bench, straight or L-shaped, up to 3-4 m on one side, 2 m on the other

- Counters are ~600 mm deep

- A single sinkhole, straight run, few curves or islands

- Bench area 10-12 m² with splashback where applicable

Labour Costs: Fabrication & Installation

Typical charges:

- Template and fabrication: $50–80/m²

- Installation and adhesive: $80–120/m²

- Sink or hob cut-outs: $150–300 each extra

- Complex installations (islands, curves): additional labour charge

Mean aggregate labour cost: between $200–300/m², depending on complexity and location.

Cost Summary: Material + Labour

| Kitchen Area | Slab Type | Material Cost (AUD) | Labour & Extras (AUD) | Estimated Total Cost (AUD) |

| ~10 m² | Neolith 12-20 mm | $5000 – $7,000 | $1,250 – $1,500 | $6,250 – $8,500 |

| ~10 m² | Dekton 12-20 mm | $4,500 – $8,500 | $1,400 – $1,600 | $5,900 – $10,100 |

| ~10 m² | Petros Stone 15mm | $1500 | $1,000 | $ 2500 |

Use our calculator to estimate countertop costs (in USD)

Note: These costs are estimates. Please confirm shipping, polishing, and installation charges with your local vendor.

Metro vs Regional Pricing

- Greater cities (Sydney, Melbourne, Brisbane): labour and delivery rates tend to be 10-20 per cent higher

- Regional/ rural communities: can impose additional delivery fees or increased wait times, and occasionally an additional $500+ per slab

Consequently, an average-level metro kitchen could potentially cost ca $1,100/m² with installation, whereas the cost of regional or remote properties may reach $1,300–$1,400/m².

Logistics, Cutting, and Finishing Costs

Beyond slab and basic labour, these additional costs are usually:

Transport Fees

- Metro: Some suppliers deliver, or it costs about $150-300 per slab

- Regional: per slab prices may be greater than $500, depending on the distance and delivery vehicle required

Cutting and Templates

- Labour cost may include simple templating and cutting, or be bundled

- However, atypical or unusual shapes or intricate island designs may add an extra price of $200-400

Edge Profiling Costs

| Edge Style | Image | Description | Typical Add-on Price per Metre (AUD) |

| Square edge |  | Simple straight cut | $0 – included |

| Bullnose |  | Slightly rounded edge | $25–40/m |

| Mitred edge |  | Thick, box-look edge | $50–80/m |

| Sharknose edge |  | Rounded underside, sharp top | $60–90/m |

Surface Finish Charges

- Matte – bringing no extra charge

- Polished gloss – this is usually 10-15 per cent higher than the cost of the materials

- Textured or custom finishes – may cost an extra $20–50/m²

Waste Management and Disposal Fees

- Most fabricators will charge $50-100 per job to recycle or dispose of off-cuts

- Others roll over waste charges in labour cost, so be sure to enquire beforehand

Full Countertop Cost: A Real Example

Example Scenario

- Kitchen bench area: 11 m², including splashback

- Slab brand: Neolith, 12 mm

- Colour/finish: Premium marble-look, polished gloss

- Edge style: Mitred edge around perimeter (~8 m)

- Cut-outs: one sink, no hob

- Location: Metro delivery and labour

Cost Breakdown Steps

- Material base price:

- Neolith 12 mm = $500/m² → 11 m² × $500 = $5,500

- Colour premium (10%):

- $5,500 × 0.10 = $550 → $6,050

- Polish finish (15%):

- $6,050 × 0.15 = $907

- Transport: Metro delivery = $250

- Templating & cutting: Basic = $500

- Sink cut-out: Standard = $250

- Edge profiling:

- Mitred edge ~8 m × $65/m = $520

- Labour & installation:

- $250/m² × 11 m² = $2,750

- Waste/recycling fees: $80

Total =

$6,050 (material+colour)

- $907(polish)

- $250 (transport)

- $500 (cutting)

- $250 (sink)

- $520 (edge)

- $2,750 (installation)

- $80 (waste)

= ≈ $11,307

Budget vs Premium Table

| Option | Description | Material + Finish | Labour & Extras | Total Installed |

| Budget | Neolith 12 mm plain matte colour | $7,700 | ~$2,500 | ≈ $10,200 |

| Premium | Neolith 12 mm marble-look polished | ~$9,740 (incl. premium & polish) | ~$4,350 | ≈ $14,090 |

This demonstrates that the optional finish options and extras, such as profiling, can add up quite fast, adding about an additional $3,500–$4,000 in total.

How to Calculate the Cost of Your Countertop (Step-by-Step Guide)

Formula

When planning a sintered stone countertop, you cannot just multiply the price per square metre by the area of the bench. You then need to include finishing costs, labour costs, and delivery costs to arrive at the actual installed cost.

Here is a simple formula that you can follow:

Total Installed Cost = (Slab price per m² × area)

+ (Finish premium %)

+ (Finish upgrade %, e.g., polish)

+ Transport delivery

+ Cutting/templates

+ Edge profiling cost

+ (Number of cut-outs × cost per cut-out)

+ (Labour rate × area)

+ Waste/disposal fee

Step-by-Step Process

- Measure Your Countertop Area

- Measure both length and width of individual countertop segments.

- Multiply length by width in each section.

- Add together all sections to obtain the total m² (include splashbacks, should you wish them in the same material).

- Find the Slab Price per m²

- Get in touch with suppliers of your desired brand, thickness, and colour.

- The standard prices with normal finishes or additional percentages on high-end colours.

- Add Finish Premiums

- Marble-look finishes or textured finishes should increase the price of the slabs by 10-20%.

- Included in polished gloss finishes, add an extra 10 15%.

- Include Transport/Delivery Fees

- Ask if it includes delivery; otherwise, add $150–500 depending on your location.

- Ask if it includes delivery; otherwise, add $150–500 depending on your location.

- Add Cutting and Templating Costs

- Custom-fit cutting templates to your specific kitchen design are typically between $300-500.

- Complex shapes or islands can be more expensive

- Add Edge Profiling

- Choose edge style: square (free), bullnose, mitred, sharknose.

- Multiply the per-metre price by the amount of your countertop edge.

- Add Cut-out Charges

- Sink cut-outs: $150–300 each

- Hob/stove cut-outs: $200–300 each

- Add Labour/Installation Costs

- Multiply your total m² by the local labour rate ($200–300/m² on average).

- Multiply your total m² by the local labour rate ($200–300/m² on average).

- Add Waste or Disposal Fees

- Many fabricators add $50–100 for offcut disposal or recycling.

- Many fabricators add $50–100 for offcut disposal or recycling.

- Sum All Costs

- Add all the above to get your total installed price.

- Add all the above to get your total installed price.

Sample Plug-&-Play Calculator Table

| Cost Item | Unit Cost (AUD) | Quantity | Sub-Total (AUD) |

| Slab material | $600/m² | 11 m² | =600 × 11 = $6,600 |

| Finish premium (10%) | 10% of the material | $660 | |

| Polish finish (15%) | 15% of the material | $990 | |

| Transport delivery | Flat fee | 1 job | $250 |

| Cutting & templates | Job fee | 1 job | $500 |

| Edge profiling (mitred) | $65/m | 8 m | $520 |

| Sink cut-out | $250 each | 1 | $250 |

| Labour/installation | $230/m² | 11 m² | $2,530 |

| Waste/disposal fee | Flat fee | 1 job | $80 |

| Total Estimated Cost | ≈ $12,380 |

Tips to Save Money Without Compromising Quality

- Select consistently standard colours and not expensive marble-like or textured designs.

- Use finer slabs (6 mm or 12 mm) with structural support when it is possible; 20 mm is wonderful but more costly.

- Choose square edge, as opposed to mitred or bullnose. Square edges are generally provided free of charge or as part of the package.

- Full-surface polish is expensive, so request polish just on the edges unless it is too expensive- matte tops but polished edges appear luxurious at a lower cost.

- Trade of bundles or provide complimentary when ordering with sink/installation.

- Compare three or more fabricators and request itemised quotes, and you can usually get significant differences in extra quotations.

- Request pieces of remnant to put on the splashback or other surfaces; less expensive than purchasing additional tiles.

- Your layout: ask the fabricator to nest your cut layout on the slab to minimise wastage (you pay per cut-out, not per unused slab).

- Leave no unnecessary cut-outs or accessory holes–they each cost.

- Recycle off-cuts: any off-cuts too small to be resold through Facebook Marketplace, Gumtree, or too valuable to reuse as side tables or plant benches are to be recycled.

Where to Buy Sintered Stone Countertops in Australia

Top Local Suppliers & Fabricators

- Giant brands such as Neolith, Dekton, Laminam, and Maximum are distributed at the national level and are frequently found in building merchants or kitchen showrooms.

- Local stone fabricators usually purchase slabs in large quantities and then do templating, cutting, and installation. They could have more competitive prices or quicker throughput.

- Renovators are likely to pair sintered stone with installation packages that combine package installation, plumbing, and cabinetry with kitchen remodels and bathroom remodels.

What to Check Before You Buy

- Brand, slab thickness, finish name and colour code – demands written confirmation.

- Request a template and installation quote separately-ensure that it is broken down into materials, labour, cut-outs, edging and extras.

- Enquire about a warranty period (most seem to have between 10 and 15 years) on factory defects, chips, fading, and general wear and tear?

- View physical samples of your selected finish, lighting, and veining may vary.

- Visit a fabrication workshop and look at the edges and cut-outs in real life, if possible.

- Ask for references or examples of other kitchens that have been installed in houses or showrooms.

Wastage Management and Smart Use of Leftovers

Typical Wastage Rate

- Fabricators typically report wastage of up to 10-15 per cent of the total slab area in bending off seams, cutting edges and cut-outs. Up to 20 per cent of waste could be observed in some complicated layouts.

Reduce Waste with Smart Layout Planning

- Ask the fabricator to nest several pieces to one slab-position sink cut-outs and bench-runs near each other to minimise wasted space.

- Use off-cuts effectively, combining splashbacks or vertical panels with bench cuts.

- Smaller benches, laundry tops, outdoor counters, or decorative wall panels can be made on remnant slabs or off-cuts.

Reuse or Resell Leftovers

- Other fabricators sell off-cuts at discounted prices (typically 30 to 50 per cent below retail), which makes them good choices when it is not necessary to have a full surface or side projects.

- Homeowners can sell the scraps on websites such as Facebook Marketplace or Gumtree. People will take the pieces to use in their DIY benchtops or furniture.

- Alternatively, any remaining stone can go in the garden–cut down to size to be used as outdoor bar counters or benches or weatherproofed.

FAQs

Is sintered stone cheaper than natural stone?

Not usually. A premium-mounted granite, quartz, or marble slab might be more expensive than a sintered stone slab. Nonetheless, its low cost of maintenance, durability, and resistance can render its total life cost lower.

How long does it take to install a countertop?

Templating to finish will take 1-2 weeks in metro areas (depending on the queue). It is typically fabricated over several days and installed in one day.

Can I install it myself to save money?

It is not advisable to fix it yourself. Sintered stone is bulky, needs professional tools, glues, and practices to be able to create an accurate template and fit. DIY errors can lead to cracks, errors in matching position, and wastage.

Does the warranty cover cracks and chips?

The majority of brands come with their limited material warranty (usually 10 years). Defects due to misuse or mishandling are not normally covered, such as cracks or chips. Check with the supplier.

Are darker colours more expensive?

Not always. There are pigments used in some dark colours which are more expensive, but some general dark finishes are cheaper than light finishes. It is better to ask at every brand.

Summary

Sintered stone provides Australian homeowners with a gorgeous, long-lasting, and durable kitchen top that satisfies the aesthetic perception of exquisite stone with less maintenance. Although it may be more expensive initially than quartz or granite, it lasts longer, allows a great degree of design flexibility, and is non-porous and hygienic; in some cases, this may make it a wise investment.

Key Takeaways

- Do not only compare prices of slab, add on costs of delivery, cutting, profiling, installation and wastes.

- Enter quotes of suppliers in the step-by-step formula and sample calculator to determine how much you will pay.

- Select standard finishes, slimmer slabs, straight edges, and minimise cut-outs to save on material costs and labour costs.

- Get several quotes with the same fabricators, request line-by-line examinations, and demand physical samples as well as warranty information.

Feel free to get in touch for a free consultation, quote, and get a detailed understanding from our experts here at Petros®. Visit https://petrosstone.com/ or call +91-8446360361 and WhatsApp

Hello!

I’m Dr Mridali, a content writer with a background in dentistry and a passion for turning complex topics into clear, engaging stories. From healthcare to architecture, I create blogs that inform, educate, and connect with readers. With every piece, I aim to blend accuracy with creativity to make information truly valuable.

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite