- Simple steps for checking the quality of Granite/Marble Slabs

- 1. Checking the Quality of Polish of the Slabs

- Hence, here is a simple method to gauge the polish quality of marble/granite using no instruments.

- 2. Checking thickness consistency in the granite/marble slabs

- 3. Checking for cracks in the granite/marble slabs

- 4. Matching granite/marble slabs with the samples submitted

- 5. Custom Sizing of Granite/Marble slabs

- 6. Checking for Porosity in Granite/marble slabs with no tools

- 7. Checking Granite/marble slabs for bends

- 8. Checking for artificial coatings/coloring

- 9. Checking for the even sizing (granite/marble tiles)

We have often noticed that procurement and quality control departments are puzzled when it comes to gauging the quality of natural stone slabs (marble, granite, limestone, sandstone or slate). To fill this gap, we have formulated an overview of simple to use techniques that anyone can use to easily check the quality of granite/marble. We will lay out very simple steps that anyone can follow. But before that, there are some basics:

First and the foremost aspect of buying stone is realizing that names of these stones don’t really matter much unless you’re looking for very popular industry-standard stones like black/grey granite etc. Best way to go is to actually see the stone slabs in person. However, this is not always practical. Samples are a great alternative, but one must know:

Never decide based on the sample alone. At the very least, a high-resolution picture of the slab is imperative. Samples cannot convey the entire picture.

If you are looking for a price list of common granite colors: click here

Being Aware of the Properties of Granite/Marble

We have seen so many projects that use white granite for their staircases. Despite our consultation, architects are adamant about using white granite which is fine but they always forget to seal it! White granite is very porous and prone to chemical attacks. Therefore, we advise our clients to use white porcite for their applications.

Thickness

In India, the customary thickness of granite slabs is 18mm, for marble, it is 20mm and differs for sandstone, limestone etc. Apart from just the thickness of the stone, there must be consistency across the thicknesses of slabs. Slabs of varying thicknesses are very difficult to work with, especially for flooring.

Simple steps for checking the quality of Granite/Marble Slabs

Quality control departments really need to revamp their strategy when it comes to gauging the quality of marble/granite. Here are some tips, that we, as a natural stone company, use to quality check our goods after they have been manufactured.

1. Checking the Quality of Polish of the Slabs

This is one of the most overlooked factors for gauging the quality of the stone. The quality of polish of the stone plays a very imperative role in the overall finish of the project. Using dull marble/granite in your projects may unknowingly take away from a pristine finish. At Petrosstone we use special surface roughness meters that gauge the quality of the surface finish for all our products. Roughness meters are expensive and not very practical in most cases.

Hence, here is a simple method to gauge the polish quality of marble/granite using no instruments.

- Prepare a sample of the stone (if possible, a sample larger than 2ft).

- Clean it to get rid of dust or dirt and make sure it is dry

- Under a bright light, turn the sample to about 45 degrees and visually inspect the quality.

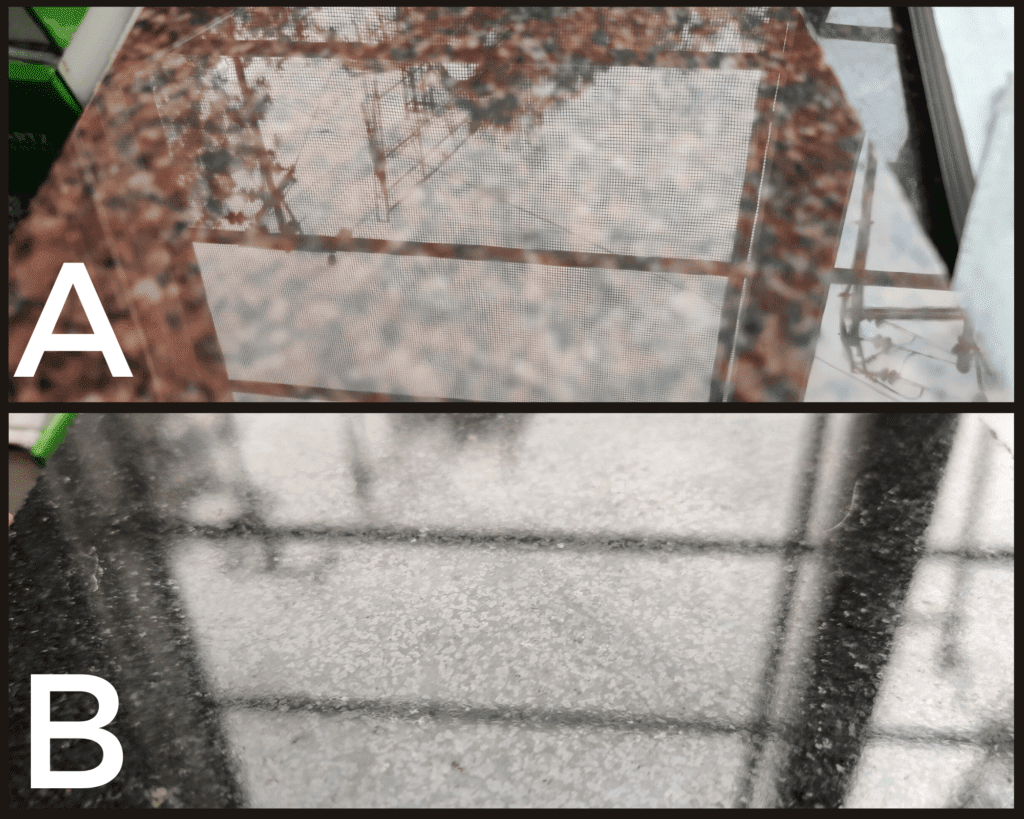

- Under these conditions, the polish quality of the sample is easily identifiable. A finely polished sample will show no patches or inconsistencies in the surface finish (A) whereas a poorly finished slab will show scratches and blurry reflections(B).

A – Perfect, high-quality polish

B – Low quality of the polish. Scratches are visible.

2. Checking thickness consistency in the granite/marble slabs

Consistency in thicknesses across granite/marble slabs is essential, especially for applications such as floorings. Checks like these are best performed when the slabs are unloaded from the trucks. This way, it is easier to sort out the non-conforming slabs onto the different stand. A tolerance of 0.1-0.3mm is acceptable, but anything over that may be a concern depending on the application of the stone.

Consistency in thicknesses across granite/marble slabs is essential, especially for applications such as floorings

3. Checking for cracks in the granite/marble slabs

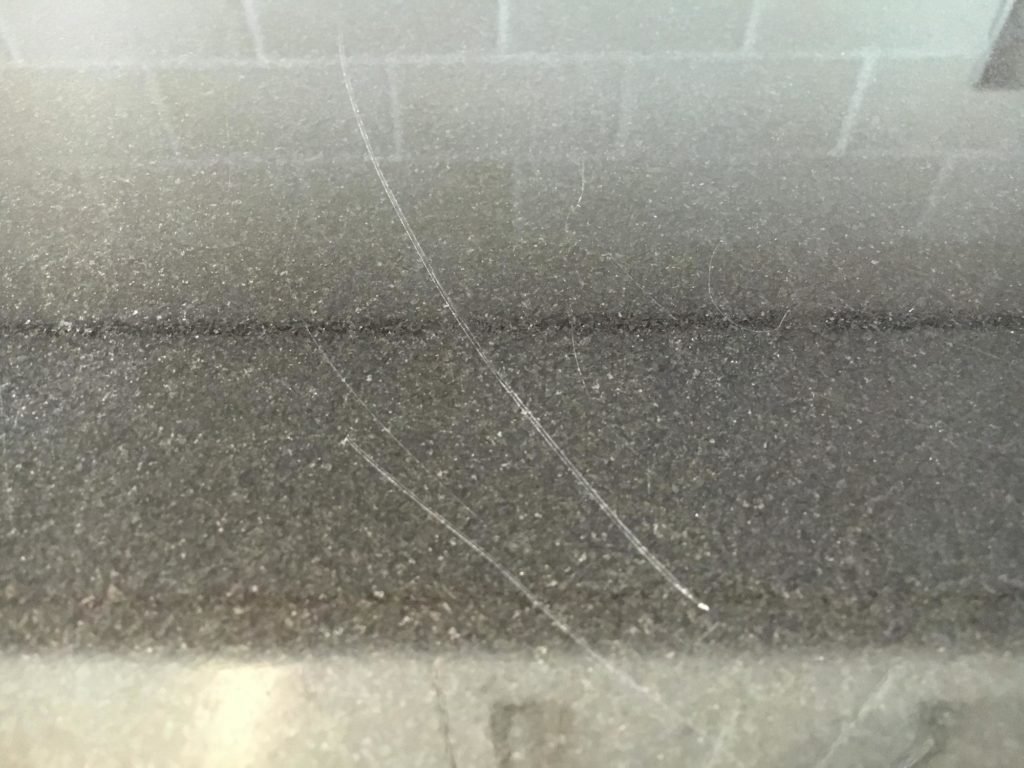

Firm slabs with no cracks/holes add the overall strength to the slab. If these will be cut into thin sizes for door and window frames, this is even more crucial. Partially damaged slabs do not hold well under stress and might break while handling.

The best way to check for such imperfections is by using ultrasonic scanners, but if the company does not have access to any visual inspection after spraying the surface with water works just fine.

4. Matching granite/marble slabs with the samples submitted

Companies must ask their suppliers to submit at least 2 samples during the selection process. One sample must, at all times, be with the quality department and the other with the procurement. When the goods are delivered, each block must be checked against these samples. We are confident that quality control departments will start noticing an enormous difference between the samples submitted and the final slabs delivered. This is because suppliers usually submit samples of fresh quality slabs (premium quality slabs) but deliver sub-par goods at the site. At petrosstone we believe in legitimate business practices and hence, refrain from any such activities that jeopardize our customer relationships. In fact, these articles on QA have been a solemn attempt to safeguard our readers from falling into such traps.

Checking for cracks in granite/marble slabs.

5. Custom Sizing of Granite/Marble slabs

Ordering your slabs to be custom sized can save a lot of time and energy spent Unlike most companies, we can provide custom-sized slabs. We can provide custom-sized slabs that best fit the required application(after being cut to size). This way, companies dramatically reduce their material wastage to the extent that it brings down the price of stone to the price of vitrified tiles!

6. Checking for Porosity in Granite/marble slabs with no tools

- A very easy method to check for porosity is to drop 3-4 droplets of lemon juice (citric acid) on the surface of the stone. If the lemon juice is immediately absorbed into the marble, it is porous. High porosity indicates poor quality.

- If the lemon juice stains the marble surface white, then the marble may contain an exorbitant amount of calcite which is again an indicator of poor quality.

7. Checking Granite/marble slabs for bends

Bends are more common in softer stones like marble. Bent slabs are complicated to work with. The most effective way to prevent bends is to use slabs thicker than 20mm. This practically gets rid of any bends.

The other way to work around bent slabs is to use weights after fixing them on the floor to correct the curvature in the slab.

8. Checking for artificial coatings/coloring

Artificial colouring can make the stone disguise its defects like cracks, lines, patches. Sometimes, even completely change its appearance. Use a tool (5-6 on the Mohr’s Hardness scale) to scratch the surface of the stone. If it does not leave a scratch, this means that the stone has an artificial colour coating. These coatings differ from sealants, which we at petrosstone use to shield against chemical attacks.

If it does not leave a scratch, this means that the stone) has an artificial colour coating.

9. Checking for the even sizing (granite/marble tiles)

If you are using granite/marble tiles for your project, it is important to check for even sizing and right-angled cuts. This will save a lot of time and energy during the fitting process. Uneven sizes with incorrect angled cuts are very difficult to deal with.

We hope you found this article helpful and we wish this helps you make better decisions when you buy granite/marble or any stone for that matter. If you want us to assist you further, then you can reach out for a free consultation and quote here.

Hi, I’m Rishabh Jain, Director – Exports & Marketing at Petros® Stone. With a deep focus on global markets and strategic growth, I’m passionate about taking India’s finest natural stones to the world, combining innovation, quality, and strong relationships to deliver lasting value.

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite