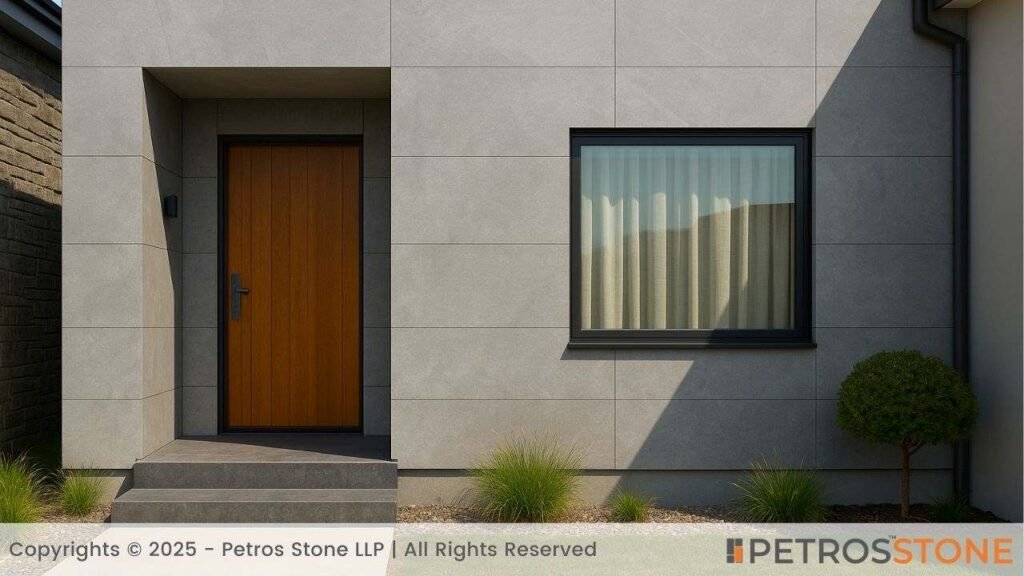

Sintered stones have become a favorite for exterior cladding among homeowners, architects, and builders. The attraction is clear: they match the sophistication of natural stones while outdoing them in terms of performance and consistency. Their durability, weather resistance, low porosity, high UV resistance, and superior stain protection are features that can protect your façade against weather ranging from tropical downpours to dry or dusty winds.

However, a fair understanding of designs and technical features of sintered stones alone is not enough to make a smart buy. A properly informed decision should reduce the distance between expectations and reality in terms of budget. This means balancing aesthetics, long-term performance, and ease in maintenance, with a ground-level understanding of best price combinations on factors ranging from slab price to transport and maintenance.

A basic cost overview of sintered stone wall cladding/facade :

Here is a biref overview that will help you estimate the costs of a sintered stone cladding materials:

| Material | Key Features | Visual Style | Colors | Common Brands | Price Range USD / Sq. Ft. |

| Marble-look | UB, heat & stain resistance | Elegant veining, polished matte | White, gray, gold, beige | Dekton, Neolith, Petrosstone, Lapitech | $2.40 – $4.60 (basic to luxury) |

| Concrete-look | Textured, highly durable, scratch resistant | Rough, modern matte | Gray, taupe, charcoal | Laminam, Petrosstone, Cadana | $2.60- $4.80 (entry to premium) |

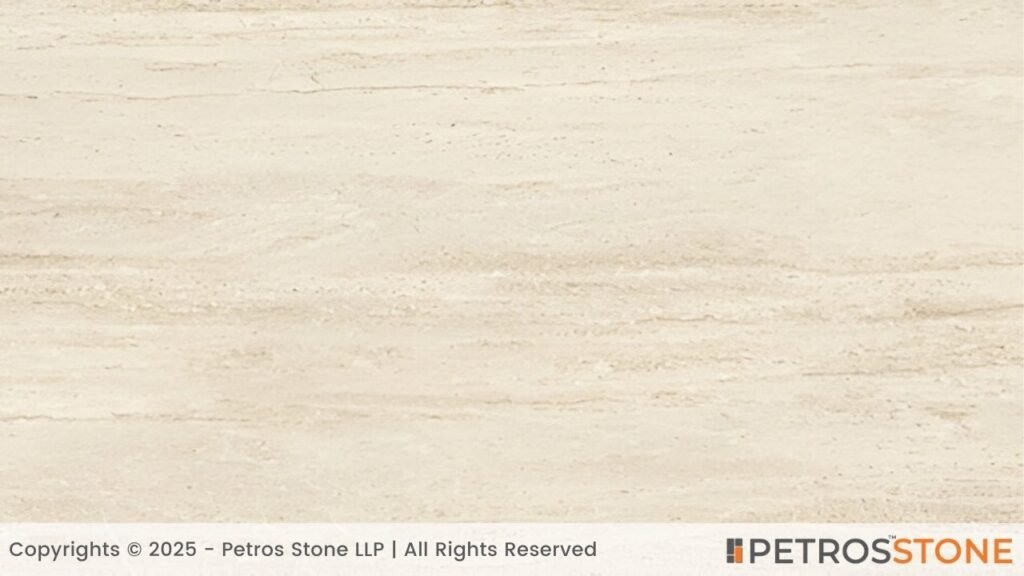

| Travertine / Stone | Natural tones, great weathering | Textured, honed, rustic | Beige, sand, light brown | ABK Stone, Petrosstone | $2.50 – $4.70(standard to custom) |

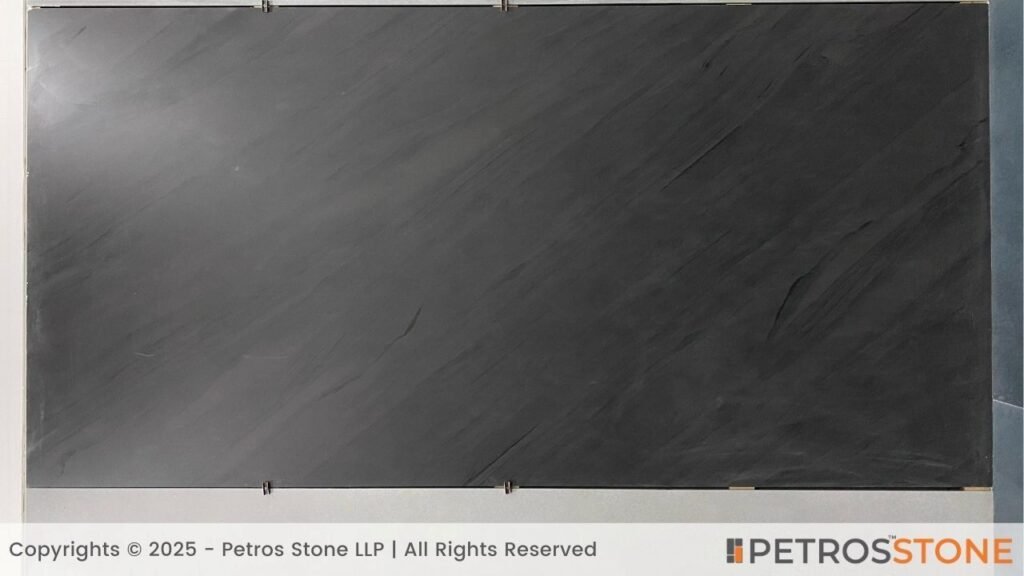

| Pure / Monochrome | Uniform, easy fabrication | Super matte, satin, gloss | White, black, light gray | Petrostone, SapienStone, Lapitech | $2.30 -$4.50 (mid to premium) |

In this article, we go deep into comprehensive cost breakdowns for sintered stone materials, cost for installation maintenance and more and also some example calculations, and run you through the key factors that influence the costing of sintered stones for exterior wall cladding.

- Key Factors That Affect Cost of Sintered Stone Cladding

- Cost Overview and Price Range

- Comprehensive Cost Calculation Breakdown

- Steps to Calculate Sintered Stone Cladding Cost

- Comprehensive Comparative Budget Table

- Other Factors that Affect Cost

- Cost-Saving Tips

- How to Integrate Cost Saving with Design

- Summary

- Key Takeaways

Key Factors That Affect Cost of Sintered Stone Cladding

The final cost is not just the slab per square foot multiplied by the total area. Here is what professionals and homeowners need to consider:

Material Costs and Thickness

- Thicker slabs (12-20 mm) might cost more, but they provide better resistance against impact. Think about how the weather, surroundings, and daily use will affect these surfaces in the long run before making a decision.

- Premium finishes like polished, weathered, or matte can raise prices by 20-30%.

- Imported slabs can shoot the base prices up owing to freight, customs, and brand value.

Design Complexity

- Simple, straight-cut panels cost less.

- The uniqueness and artistic value of a tile’s patterns and colorways affect its base price.

- Complex geometric cuts, curved profiles, or intricate inlays may hike up fabrication costs due to advanced digital techniques.

- Matching veins across panels calls for precision-cutting and adds wastage.

- Complex cladding layouts and irregular or abstract facades can cause high wastage. This should also be considered in material estimates.

- Remuneration for artistic designers might cost more than the tiles themselves, due to their background and the vision they bring to the table.

- Decorative elements such as rebates, mitters, or chamfered edges demand precision craftsmanship and extra labour.

Professional Installation

- Labor charges depend on location. Installation rates are higher in metro cities than in smaller towns or rural areas.

- Skilled labor is necessary for handling large-format tiles, where even a small mistake can lead to costly replacements.

- Rare projects with complex design layouts and visions call for top-tier professionals or companies, with budgets varying based on their experience and profiles. Compromising with local, low-experience professionals might derail the design vision and leave the project in no man’s land.

- Building heights shift the costs. Multiple stories mean increased safety measures and appropriate labour with efficiency to do that.

Transportation and Logistics

- Some large-format sintered stones call for delicate handling, or even custom crating.

- Long-distance shipping can add 5-20% to the total cost.

- Access constraints at the project site and career insurance also add up to the cost.

- A-frames or reinforced packaging for large-format tiles can raise handling fees.

- Ocean freight and custom fees should be taken into consideration for imports.

Local Taxes and Import Duties

- Duties on imported stone, local sales taxes, and regulatory charges (U.S. state GST or environmental levies) can silently spike the total spend.

- Local municipal taxes also add to the GST/VAT equivalents.

Finishing and Sealing

- Most of the sintered stones are pre-sealed. But some require on-site sealing after installation.

- Sintered stones don’t fade that easily, but UV-resistant coatings are a good investment in the long-run for sunny, humid, or pollution-prone zones.

Maintenance

- Routine deep-cleaning contracts and protective coatings can be added to the annual upkeep. But, unlike natural stones, they may not be required as frequently. Consider the brand and build quality before making such calculations.

Cost Overview and Price Range

| Material | Key Features | Visual Style | Colors | Common Brands | Price Range USD / Sq. Ft. |

| Marble-look | UB, heat & stain resistance | Elegant veining, polished matte | White, gray, gold, beige | Dekton, Neolith, Petrosstone, Lapitech | $2.40 – $4.60 (basic to luxury) |

| Concrete-look | Textured, highly durable, scratch resistant | Rough, modern matte | Gray, taupe, charcoal | Laminam, Petrosstone, Cadana | $2.60- $4.80 (entry to premium) |

| Travertine / Stone | Natural tones, great weathering | Textured, honed, rustic | Beige, sand, light brown | ABK Stone, Petrosstone | $2.50 – $4.70(standard to custom) |

| Pure / Monochrome | Uniform, easy fabrication | Super matte, satin, gloss | White, black, light gray | Petrostone, SapienStone, Lapitech | $2.30 -$4.50 (mid to premium) |

Note: The thicknesses used above as reference for cost calculation are mostly 6mm and 12mm. Prices may vary based on the type of finish, brand exclusivity, and whether they are imported or domestically sourced.

Next, we will provide a detailed cost calculation breakdown – with all key components included – for sintered stone cladding for house exteriors.

Comprehensive Cost Calculation Breakdown

Material Cost

- Great brands like Neolith, Dekton, Petrosstone and Lapitech might cost more. But they are unparalleled in quality assurance and warranties.

- Format and size matters. Usually facade slabs are large format – 118” x 59” or 3m x 1.5m – with thickness between 6mm and 12mm. Thicker slabs, jumbo formats or pattern-matched sets cost higher.

- Matte, gloss or textured finishes have different costs. Decorative finishes like marble-like look or deep-blacks come at premium prices.

- Price range for basic materials range from $2.30- $4.80 per square foot.

- Imported slabs might face tariffs. This might push material costs up by 5-20% , depending on the vendor and place or origin.

Fabrication and Cutting Costs

Profiling and Custom Shaping

Professional fabrication is a must for profiling and custom shaping. Typical charges range between $5 to $25 per square foot.

| Type | Price Range |

| Basic straight cut | $1.20 – $2.50 |

| Complex edge profiling | $2.50 – $3.00 |

| Curved cuts, custom drain slots, rebates | $3.00 – $3.25 |

Pattern Cutting

- Some intricate designs like mosaic, inlays and matching veins may cost higher on labor due to digital templating and bridge saw technology.

- Efficient slab layouts can reduce wastage and fabrication costs.

Installation Charges

- When it comes to labor rates, it differs from metro to village areas. An experienced installer in a metro area can charge between $40 – $60 per square foot. In suburban areas, professional installers could charge $25 – $35 per square foot. Multiple stories or scaffolded works may add extra to this price.

- Before the stone goes up, an installer needs to build a supporting frame, add waterproof layers and reinforce the wall. This prep work can cost between $2 – $7 per square foot. For ventilated facade systems, the cost of mechanical anchors will also have to be weighed in.

- Adhesives, grouts, and fasteners can add $2 – $5 per Sq. Ft. to the project.

| Adhesives | $1 – $2 / Sq. Ft. |

| Grout / Joint compound | $0.50 – $1 / Sq. Ft. |

| Clips, spacers, speciality fasteners | $0.50 – $2 / Sq. Ft. |

Transportation, Local Taxes

- The cost per kilometer for getting the slab from supplier to site can cost from $2 to $6 per square foot for short, local trips with standard handling. For rural sites, or longer distances, this can rise to $6 to $12 per square foot. For extra-large slabs, custom crates might be needed. This might add $50 to $100 per crate.

- Large format slabs usually require heavy-duty pallets, cranes or extra workers. For projects with a standard size of over 500 square feet, this special handling can cost $300 more per shipment.

- The state sales tax usually adds up to 9% of the total, based on the location. For imported shipments, GST-styled tariffs might apply. Confirm this percentage with the supplier or agent before finalizing the budget.

Finishing and Sealing Costs

- Panels usually come pre-sealed, which means they already have a protective layer. But for some sintered stones, used especially for walls exposed to rain or dust, extra treatments after installation might help in the long run. Post-install options like a moisture barrier, anti-graffiti coat, or stronger UV layer cost between $2 and $5 per square foot.

- Extra UV-resistant coating for sunny or polluted areas can help in preserving the color and finish of your façade. Usually done at the factory, or on-site, this costs around $3 to $8 per square foot. Some homeowners re-apply it yearly for added protection, but not every project needs these extra steps.

Maintenance

- Sintered stones demand very little care. Done every few months, a self-clean or pressure wash costs about $0.30 to $0.70 per square foot.

- For deep cleaning, graffiti removal or stain treatment, expect $1 to $3 per square foot.

- For some massive facades, some homeowners opt annual contracts which can run from $500 to $2500 depending on the size.

- Most brands offer warranties for 10-20 years. But accidental damage is not included in this. Extended warranties can cost between $500 to $1500 depending on the size of the project.

Steps to Calculate Sintered Stone Cladding Cost

| Step 1 | Work out the materials required. Measure total wall area, add 10-15% extra for offcuts and wastage. Pick preferred slab size, thickness, and finish. |

| Step 2 | Choose the material and price range. Select your brand and style – whether you want basic or premium options. Multiply the total cladding area by the price per square foot to get your base material cost. |

| Step 3 | For fabrication costs, factor in cutting, shaping, and profiling charges. Simple cuts cost less, while complex designs cost more. Optimal layouts can help reduce waste and expense. |

| Step 4 | Get quotes from installers. While getting the quote, include prep work like framing, waterproofing, and reinforcements with adhesives, grout, and fasteners. |

| Step 5 | Add delivery costs based on distance and the site type. Consider the size of the panels here, as oversized slabs may need extra crane, crates, or labor. |

| Step 6 | For imported slabs, apply tariffs or duties; otherwise, include state sales tax for materials and labor. |

| Step 7 | Ensure your slabs are pre-sealed; otherwise, include cost for moisture barriers, anti-graffiti coats, and UV protection. |

| Step 8 | Include a place in the budget for occasional cleaning or extended warranties. Annual contracts are worth considering for larger facades. |

Comprehensive Comparative Budget Table

Using the 8 steps provided in the previous section, here is a comprehensive comparative budget table for a 100 square feet residential house, a 500 square feet medium villa, and a 2000-3000 square feet high-rise apartment.

| Budget Step | Small Residential (100 Sq.Ft.) | Medium Villa (500 Sq.Ft.) | High-Rise Apartment (2,000–3,000 Sq.Ft.) |

|---|---|---|---|

| Step 1: Area + Wastage | 100 + 10% = 110 Sq.Ft. | 500 + 10% = 550 Sq.Ft. | 2,500 + 10% = 2,750 Sq.Ft. |

| Step 2: Material Cost | $275 to $495 | $1,375 to $2,475 | $6,875 to $12,375 |

| Step 3: Fabrication | $1,100 to $2,750 | $4,400 to $11,000 | $19,250 to $49,500 |

| Step 4: Installation | $3,300 to $6,600 | $15,400 to $30,250 | $68,750 to $132,000 (+ $10–$20/Sq.Ft. extra for multi-story) |

| Step 5: Transportation | $400 – $1,200 | $2,000 – $5,000 | $8,000 – $20,000 (complex site handling) |

| Step 6: Local Taxes & Duties | $600 to $2,000 | $3,000 to $5,500 | $12,000 to $25,000 |

| Step 7: Finishing & Sealing | $330 to $880 | $1,375 to $3,850 | $5,500 to $17,875 |

| Step 8: Maintenance / Warranty | Annual: $100 – $400Warranty: $500+ | Annual: $350 – $1,200Warranty: $1,000+ | Annual: $1,500 – $3,500Warranty: $5,000+ |

| Total Estimated Cost | $6,105 to $14,325 | $27,900 to $59,075 | $141,875 to $259,250 |

Note:

- These are sample calculations done without choosing any specific tile, supplier, or layout. Consider it only as a guide to reach your price estimate.

- When budgeting, always add a 5 – 10% contingency to avoid running out of funds before completion.

- Intricate, visionary, or artistic designs cost more, depending on the creative vision and project complexity.

- For transportation, original quotes may vary based on road type, distance, travel complexity, and terrain conditions.

- Check the jurisdiction to know local taxes and duties.

- Annual cleaning and warranty contracts vary by supplier and project size.

Other Factors that Affect Cost

- Living near the manufacturer’s hub can significantly reduce the shipping charges. So if you happen to have a slab manufacturer nearby, it’s ideal to check what they’ve got.

- Geopolitical issues, tariffs, and shipping delays can cause price fluctuations and variations. Fuel surcharges may affect the pricing, too.

- Some areas have regulatory or sustainability requirements. Certain building codes or green certifications requiring specific materials or treatments can add to the cost.

Cost-Saving Tips

- Green-certified products offer incentives and longer lifespans.

- Use optimal slab thickness without going overboard.

- Plan panel layouts not just for design, but also to reduce wastage.

- A minimalistic design perspective can be more attractive and also more cost-effective than complex, intricate designs.

- Buy in bulk for supplier discounts.

- Modular cladding systems can be cheaper and faster.

- Factory pre-sealing can save on-site labor costs.

- Extended warranties can avoid unexpected surprises in the long run.

How to Integrate Cost Saving with Design

- Let the budget guide material and finish choices.

- Pick colors and looks that achieve your vision, without going for costly fabrication.

- Choose slab sizes that allow for installation in fewer cuts.

- Use systems that allow for future expansion, without major changes.

- Work closely with installers and fabricators, while also granting them necessary freedom, to avoid unexpected shocks.

Summary

High-income homeowners are usually free to make their choices without any budget constraints. But for others, exterior cladding takes up to 10-15% of their total construction budget. If the design is high, it can jump to even 20%. In that case, it is always better to stay prepared to avoid unlikely surprises.

Getting a detailed, transparent cost estimate for your sintered stone cladding ensures that your project runs smoothly and stays on budget. When you are involved in every detail – from material to maintenance – you are not only cutting costs, you are also shaping every aspect of your home exactly as you want, with complete control. With smart planning and sourcing, your exterior can deliver value and performance for decades without overshooting your budget.

Key Takeaways

- Sintered stones are perfect for exterior cladding. But if you think that they are cheaper than natural stones, know that the prices can vary greatly based on many other factors.

- Material cost is only one part of the budget. Installation, fabrication, transportation, and finishing up can matter just as much – or even more.

- Location, climate, and design complexity can raise or lower the total cost.

- Early planning helps set realistic budgets. Get detailed, transparent quotes using the steps and information in this blog to support informed decision-making.

Feel free to get in touch for a free consultation, quote, and get a detailed understanding from our experts here at Petros®. Visit https://petrosstone.com/ or call +91-8446360361 and WhatsApp

Hi, I’m Hemanth, a storyteller at heart with a background in journalism, screenwriting, and brand writing. At Petros Stone, I explore the stories behind materials and transform technical details into content that’s clear, creative, and easy to act on.

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite