Stone staircases have the elements of natural beauty, architectural purity, and robustness. They lead to a feeling of permanence, class, and a grounded vocabulary of the earth, whether in the lobby of an apartment, the landscaping of a garden, or the entrance of a building.

Among these, the stone treads are the parts that you set your feet on, located horizontally, and they have a significant role in safety, aesthetics, and structural performance. The correct stone tread selection establishes the tone: refined and smart interior; grooved and non‑slippery exterior.

In this comprehensive guide, we aim to cover everything about stone staircase treads, including terminology, design, installation, maintenance, and sustainability. We have streamlined the information into rational sections.

- Terminology Used in Stone Staircases

- Terms to Describe Natural Stone Stairs

- Different Components of Natural Stone Staircases

- Different Types of Natural Stone Stairs

- Classifying Stone Stairs by Design

- Classifying Stone Stairs by Location

- Standard Sizes and Thicknesses for Stone Stair Treads and Risers

- Stone Finishes for Treads and Risers

- Design and Aesthetic Considerations

- Installation Methods and Tips

- Maintenance and Durability

- Pros and Cons of Using Natural Stone for Stair Treads

- Cost Considerations

- Sustainability and Eco-Friendliness

- Choosing the Right Stone for Your Stair Treads

- Inspiring Design Ideas and Use Cases

- Summary

- Key Takeaways

Terminology Used in Stone Staircases

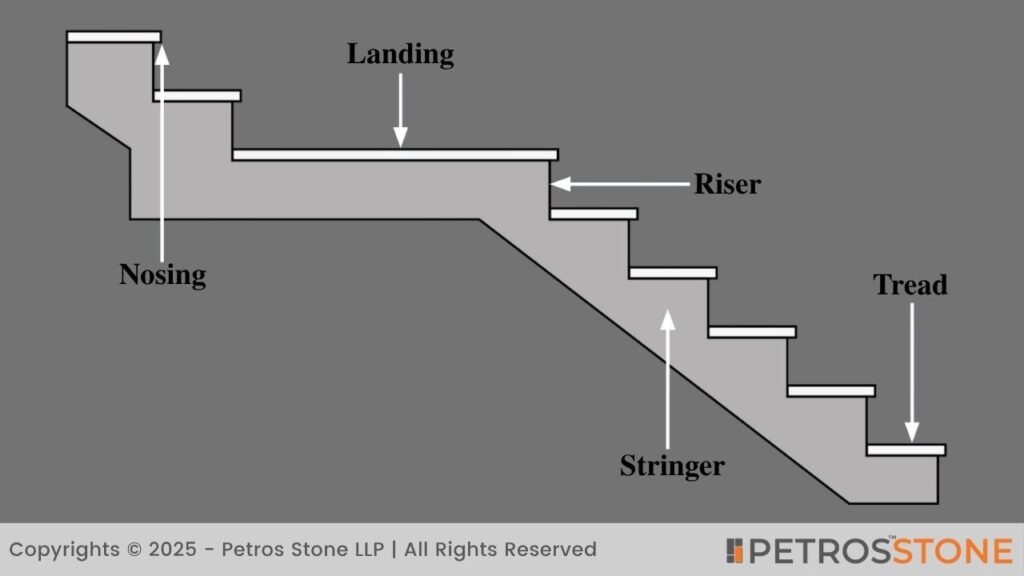

Tread

The horizontal surface of a step. It is the supportive foot. Stone treads in stone staircases have to be thick and robust, typically 30-60 mm or so, depending on the site.

Riser

The face of the stairway, which is vertical between two treads. Risers help keep the steps up and are a part of stair design and auditing.

Nosing

The bulging inward edge of the tread. A safe but comfortable step is achieved by a well-shaped nosing. It can be an overhang riser by 10-20 mm.

Landing

A level surface that is inserted between stair runs or at the top/bottom. Landings provide a rest area and aesthetic pause, as well as tend to reflect the substance of treads.

Stringer

Stairs side support structure. The stringer on natural stone stairs can be concrete, steel or stone itself and is laid beneath or alongside the treads and risers.

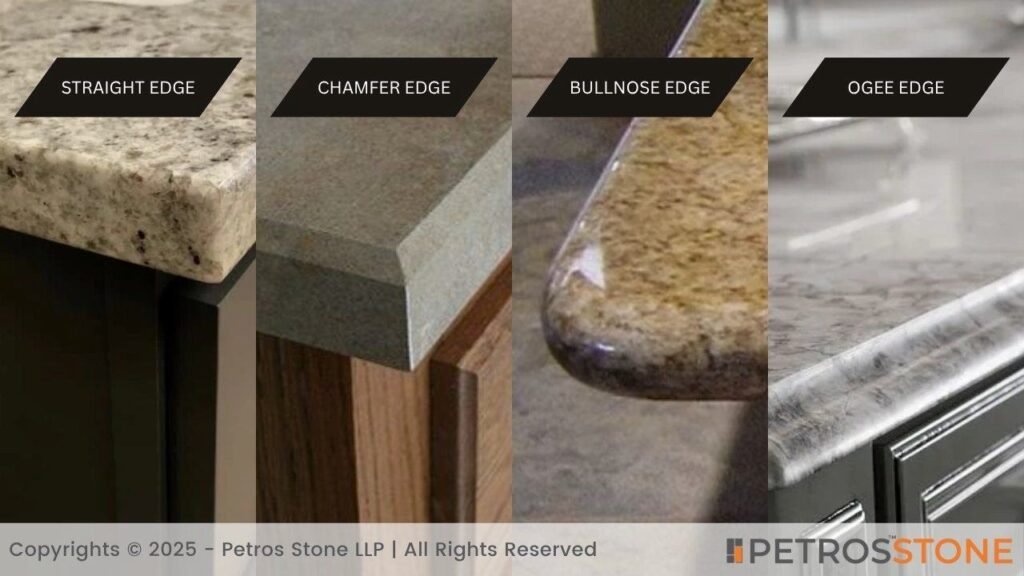

Bullnose Edge

Smooth, classic nosing edge, takes off sharpness. Fashionable when indoors or by the pool to tone down the look.

Chamfered Edge

Cut at an angle of 45 degrees down the edge to enhance the longevity of the edges and have a smooth, angular appearance.

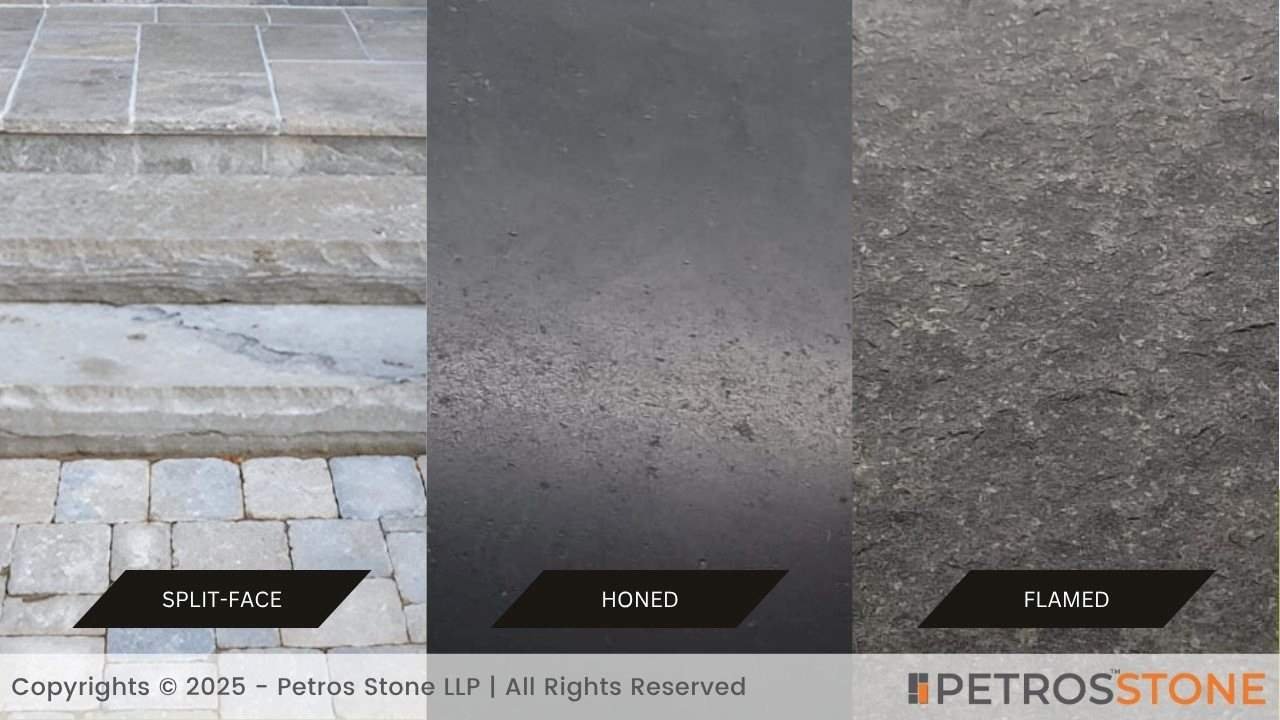

Flamed Finish

Popping mineral grains by high-heat processing of granite or quartzite to form a rugged, non-slippery surface-great outdoors.

Honed Finish

Fine-grinding with the low-sheen and smooth surface. Does not hurt on the feet, stylish, and less shiny than any polished one.

Split‑Face Finish

Stone was cut according to natural cracks and revealed its raw texture. Very rustic: even landscape design or old-world architecture.

Terms to Describe Natural Stone Stairs

Freestanding vs Embedded Stairs

- Freestanding: independent structure. Treads lie on stringers or metal supports. Best suited to sculptural or floating steps.

- Embedded: treads and risers are fixed in walls or concrete. Structural stairs have more common and stable approaches.

Monolithic Stairs

Steps hewn out of a block or slab of stone. Monolithic designs tend to consist of granite and are rather seamless, durable, and have enormous visual weight.

Stepped Stones vs Continuous Slabs

- Stepped stones: the steps are separate pieces of stone. More easily replaceable.

- Continuous slabs: a long, unbroken piece of stone carved that creates a multinaar of tread and risers. Sleeker looking aesthetically, with fewer joints.

Functional vs Decorative Steps

- Functional stairs support foot traffic used on a day-to-day basis (e.g. home or office).

- Ornamental stairs are decorative stairways, typically intended to be placed in a garden or showroom, and are less susceptible to heavy traffic.

Landscape vs Structural Stairs

- Landscape stairs are primarily used in landscape applications, usually in the garden or patio. They can provide broader, less deep rises in the textured finishes.

- Structural stairs are code-constructed structural stairs which are designed to carry heavier loads (residential to commercial), both interior and exterior, within architecture.

Different Components of Natural Stone Staircases

Stair Treads

- The common household indoor treads are 30 mm thicker.

- Heavy use and outside treads are usually 40-60mm or more.

- There may be variation on depth (front to back), which is usually between 250 and 350mm, and length is dependent on the width of the stair.

Stair Risers

- Typically 150180 mm tall.

- Thickness is varied-20-30 mm when laid over concrete, when cladding, or the same as treads on monolithic stairs.

Stair Base/Foundation

A good foundation is a must. Typical builders use:

- Gravel or crushed stone sub-base

- Mortar bed or concrete slab

- Outdoor stairs or wet areas, waterproof membrane (outdoor stairs or wet environments)

Edge Profiles

Typical profiles are:

- Straight edge: edgy and contemporary

- Chamfer: soft bevelled edge

- Bullnose: smooth front curve

- Ogee: ornamental S-moulding

Make decisions on safety, style, and durability. Chamfered or rounded edges avoid chipping.

Coping and Trims

Coping caps reveal the edge of walls (e.g., at the edge of landings), guard wall material, and are integrated visually with treads. Landings or side walls can be lined with a trim piece.

Drainage System Considerations

Essential to exterior steps:

- Minor inclination to the stair nosing

- Weep holes or concealed drip edges to drain water away

- Splits or fissures through which water can leak out

- Treads under permeable grout or drainage mesh

Different Types of Natural Stone Stairs

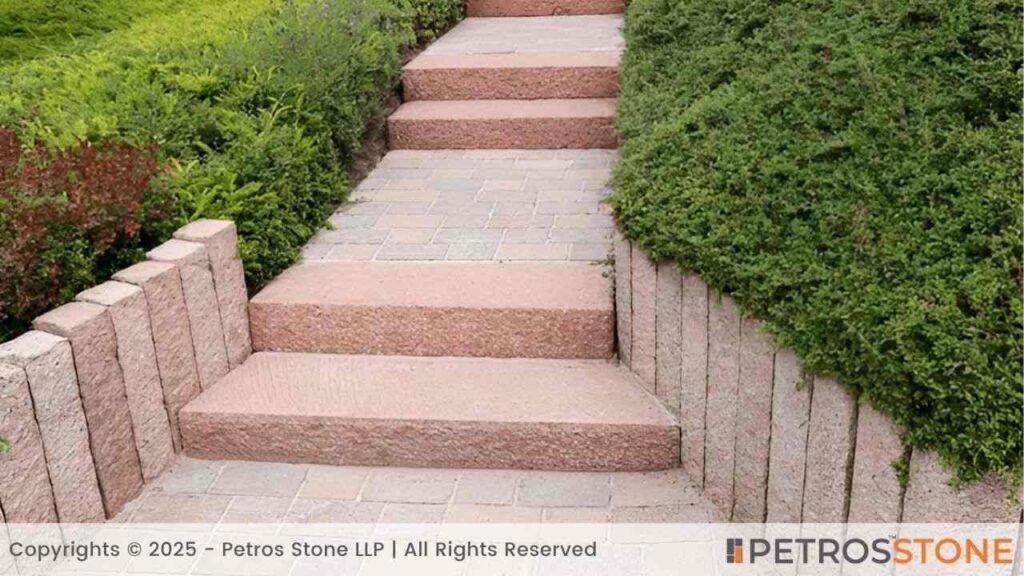

Granite Stone Stairs

Granite is very hard and does not scratch or stain. Appropriate for heavy traffic areas and the great outdoors. Characteristics are small flecks or a crystalline shine. Finishes available: flamed, slip resistance; honed, elegant interiors; polished, gloss depth.

Limestone Stone Stairs

Softer—warm, yet muted in colour, cream, beige, buff. More easily cut and carved edge work. Proposes a Mediterranean or classical aesthetics. Easily abraded and marked, so indoor or plush poolside usage.

Sandstone Stone Stairs

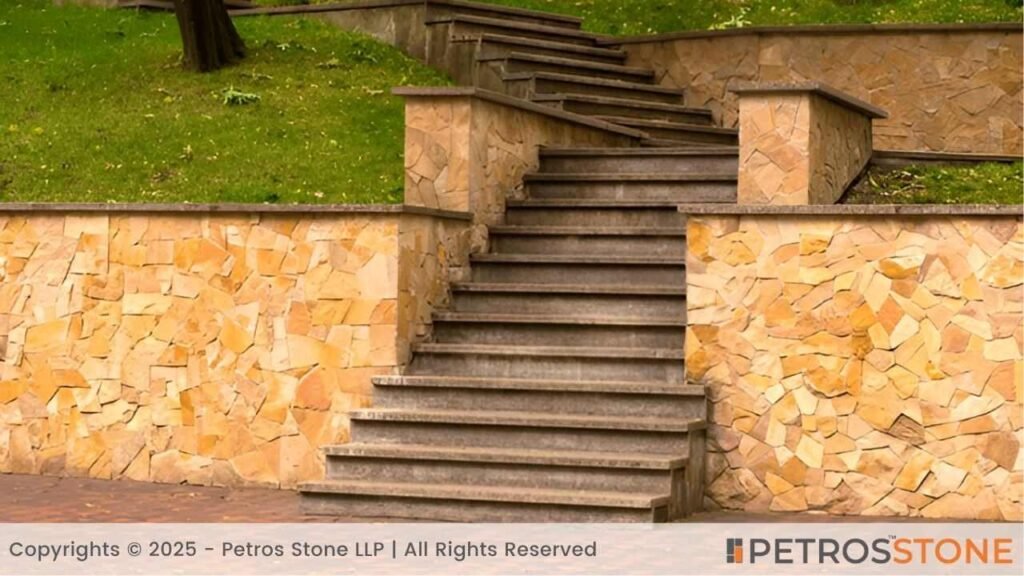

Warm, textural, and geological character. Roughness creates friction. There are browns, reds, and earthy colours. This would be appropriate for rustic decks or garden staircases.

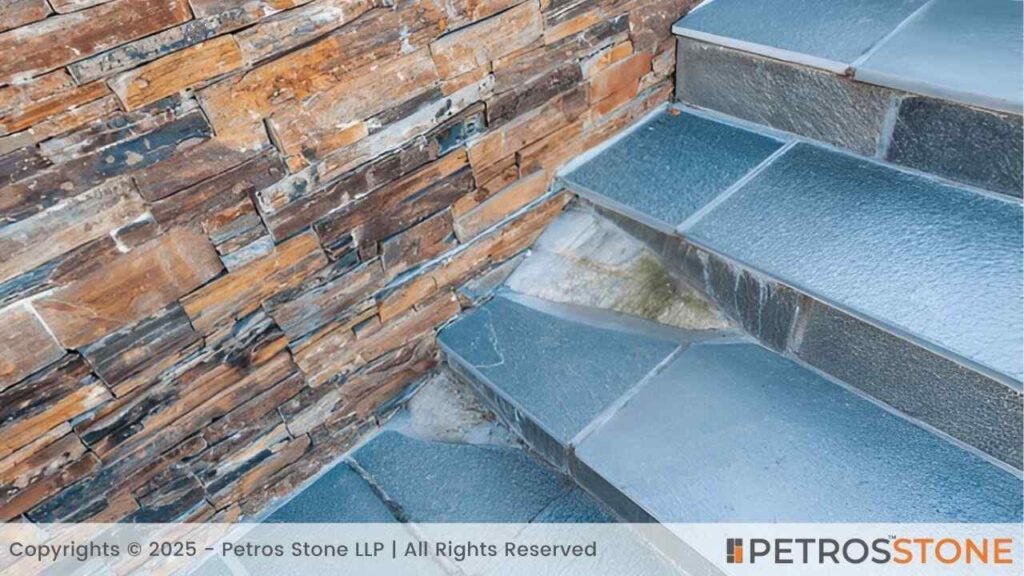

Bluestone Stone Stairs

A sort of compact sandstone or feldspathic sandstone of blue-grey colour. Thick and tough. Flamed or natural cleft finish is slip-resistant. Trendy land, graceful entrance steps.

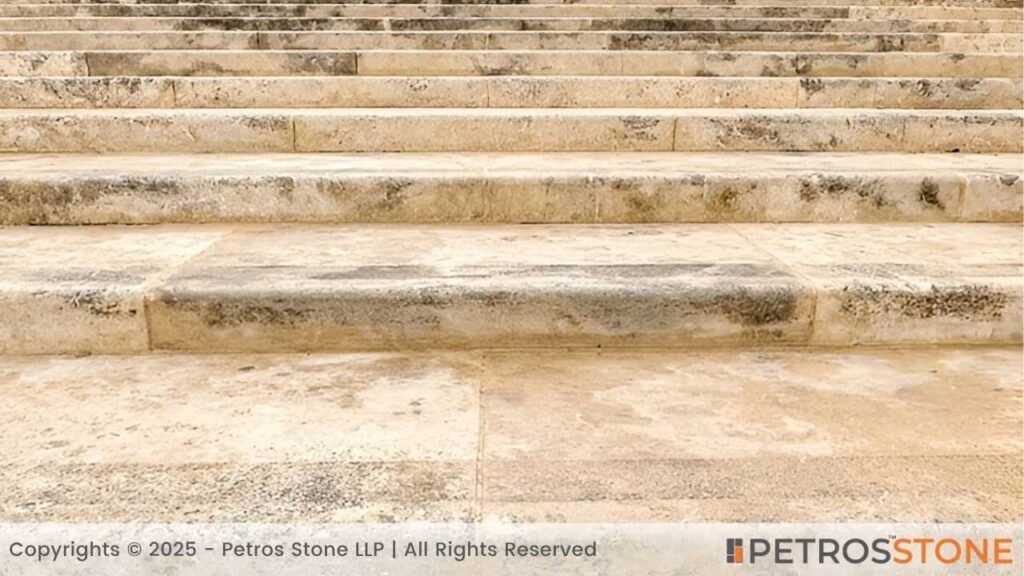

Travertine Stone Stairs

Rough limestone of the sort featuring holes and twirls. Lighter colours and softer touch underfoot. Also, typical around pools or patios can be honed or filled. They should use mild weather.

Slate Stone Stairs

Metamorphic rock of fine grain. Texture in layers and clefts. Perfect in moist locations: patio, garden. Naturally slip-resistant. These are black, grey, green, and purple. It allows layering, which makes it a bit less predictable in thickness and strength.

Quartzite Stone Stairs

Hard metamorphic stone which looks a little like marble, being finely veined but more strenuous. Delivers brilliance and shine; more powerful than granite. Suitable for polished staircases indoors or on outdoor robust tread steps. Flamed or honed finishes in stock.

Classifying Stone Stairs by Design

Solid Block Stone Stairs

A single stone block is carved to produce each tread/riser (many times). Thick, sturdy, classy. Ordinarily, inside or as a monolithic outside running-strong bearing base is necessary.

Veneer‑Clad Concrete Steps

It is cast in place, facing on the outside with stone veneer treads and risers. Stone appearance at reduced weight and price. Concrete serves as structural; stone veneer serves as finishing.

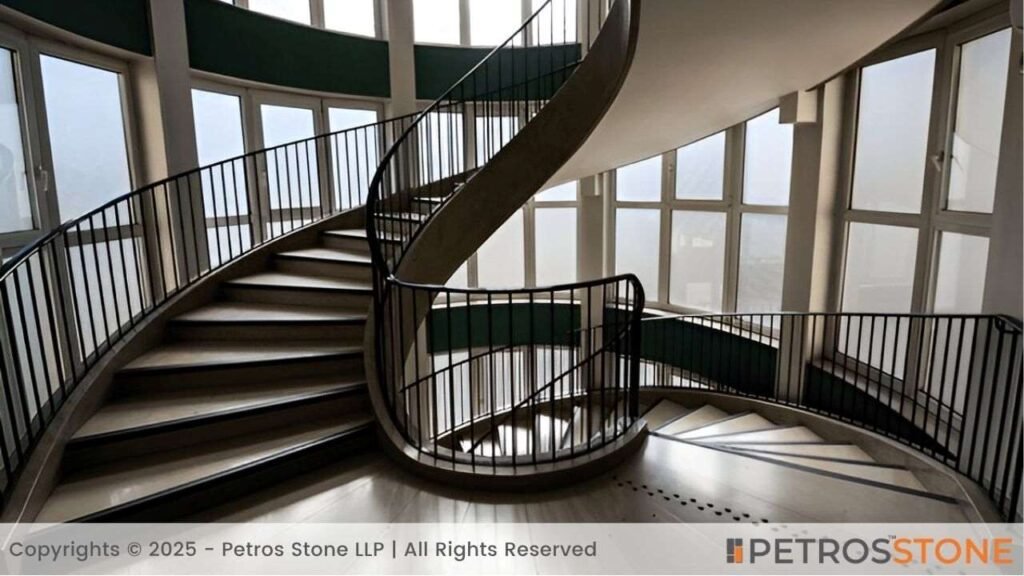

Floating Stone Staircases

Treads are unsupported and appear to be unattached. Treads are fastened by hidden supports (steel or concrete) to the wall or stringer. Light and minimalistic in appearance, it is trendy in modern interiors.

Cantilevered Stone Steps

The outer end of each tread is inserted into a load-bearing wall. Its other side faces outwards without support. Impact aesthetic but necessitates civil engineering and safe fastening.

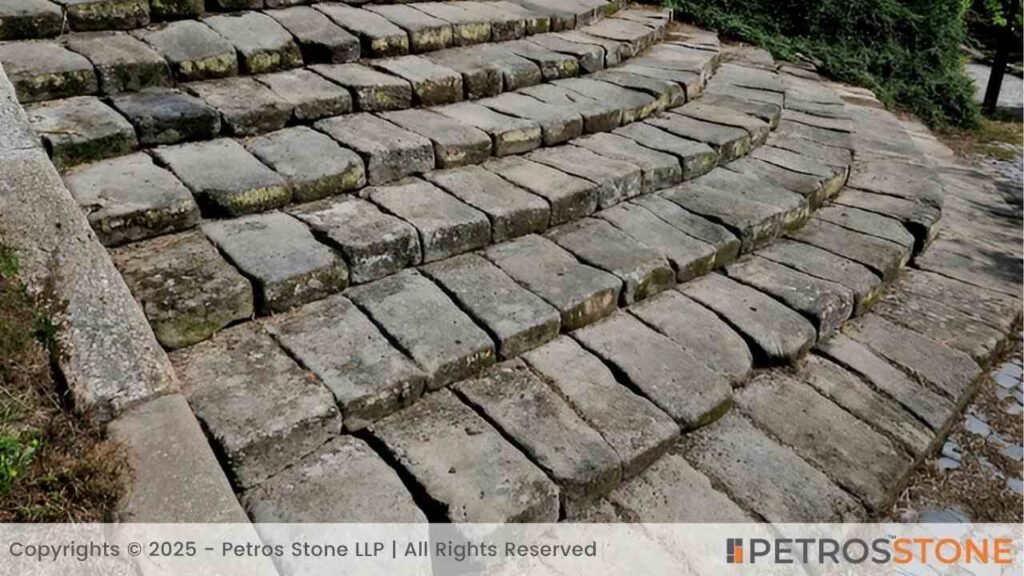

Stepping Stone Pathways

Not a full staircase, but broad courses of stone laid down like steps, up and downs, or even along lawns. Typically low risers, 50-100 mm high. Ideal garden, park, or zen pathway.

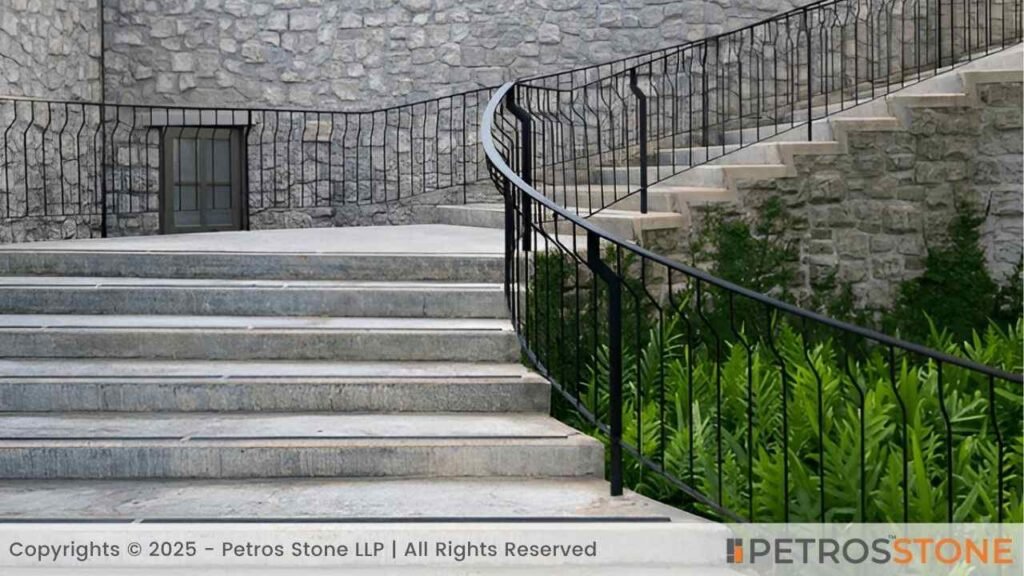

Spiral and Curved Stone Stairs

To construct spiral or sweeping curves, use cutting blocks in the form of wedges, or let the slabs be continuous and curved. The treads are tapered.

Classifying Stone Stairs by Location

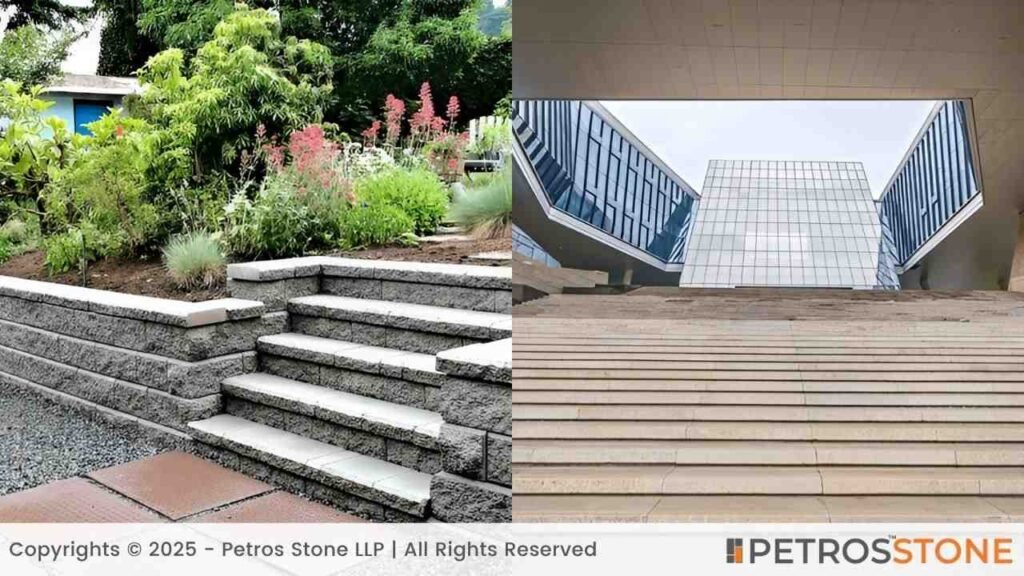

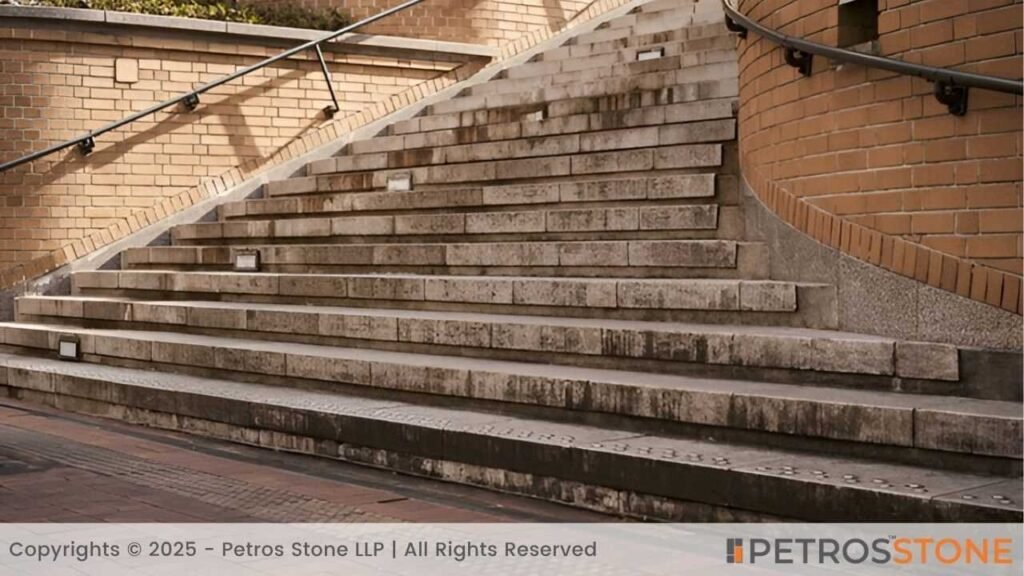

Outdoor Stone Staircases

Needs to be able to resist weather, freeze-thaw, UV, and moisture. Use solid rocks such as granite or quartzite. Others offer traction such as flamed, sandblasted or bush-hammered finish. Slope and drainage that is vital to avoid standing water.

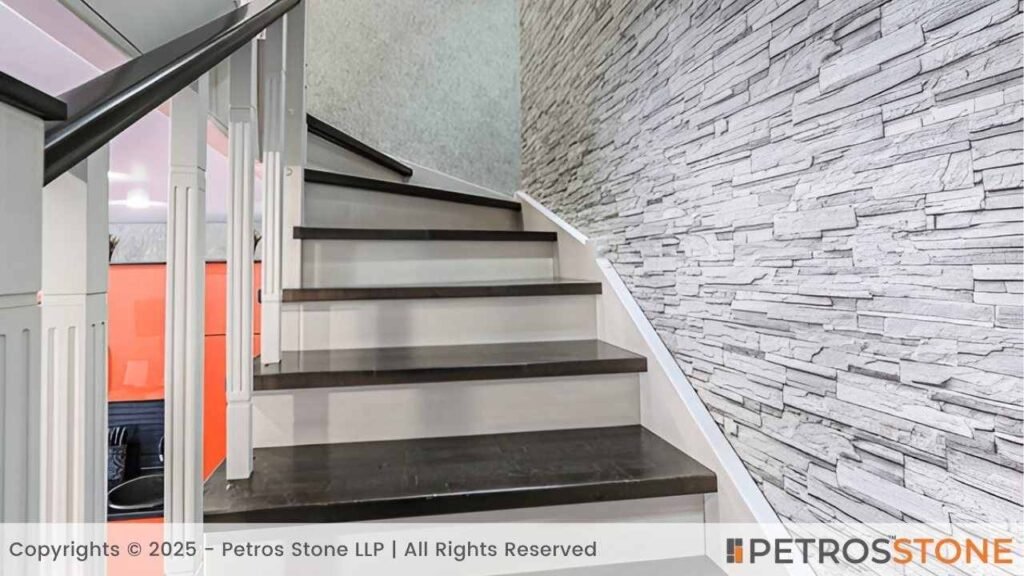

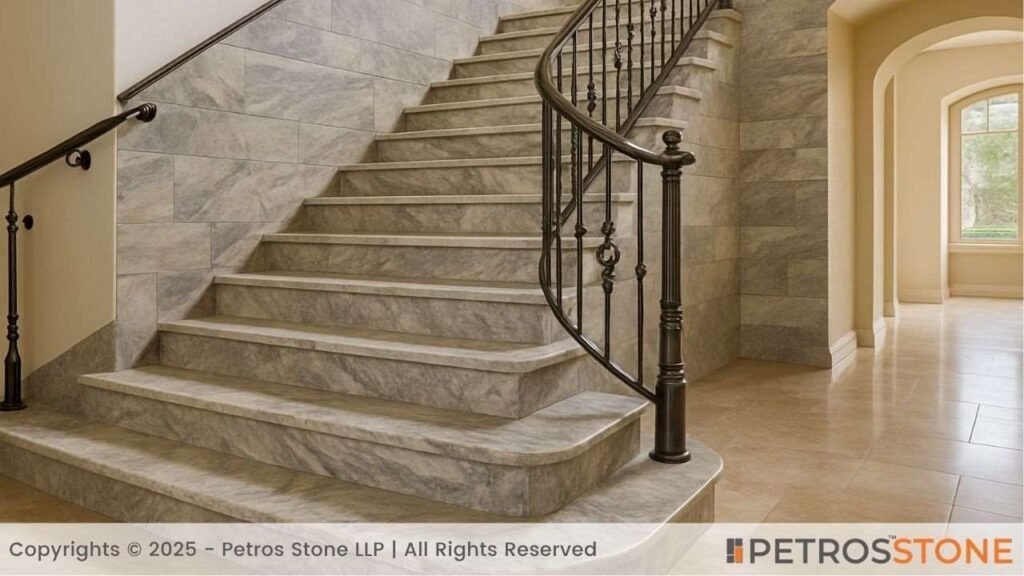

Indoor Stone Staircases

An emphasis is put on aesthetics and comfort. Polished or honed surfaces are usual. Softer rocks such as limestone or travertine can be used, provided traffic is moderately high and cushions or mats are needed.

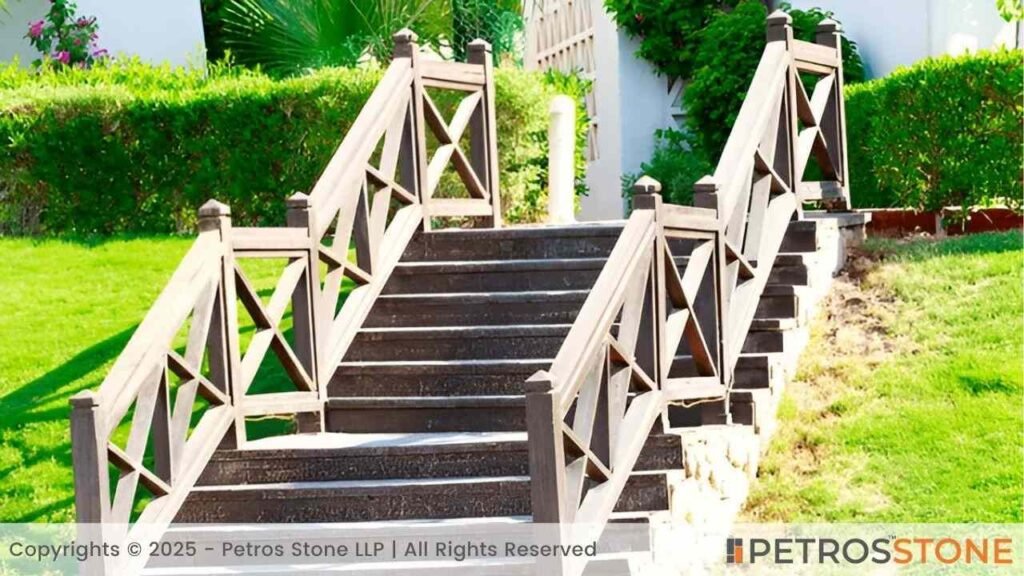

Garden and Landscape Steps

Blends with trees and terrain. Raw cuts, rough edges, embedded planting troughs. A natural look is achieved by using stepping-style or chunky stone blocks.

Patio and Poolside Steps

Frequently cooled by water and shade. Temperatures: travertine is cool on the feet. Slip-resistance essential; solution is flamed or sandblasted finish preferred. Drain well to prevent algae.

Entryway Stone Steps

First impression is important- granite, bluestone, or quartzite are usually utilised. Solid, beautiful, and easy to care for. Finishes can be flame at the top surface with bullnose or chamfer edge to be safe and have style.

Standard Sizes and Thicknesses for Stone Stair Treads and Risers

Common Tread Dimensions (Length × Width × Thickness)

| Location | Length (mm) | Width (mm) | Thickness (mm) | Notes |

| Indoor | 900–1200 | 250–300 | 30–40 | Standard for typical house staircases |

| Outdoor | 900–1200 | 300–350 | 40–60 | Extra thickness for durability |

| Narrow/tight | 600–800 | 250–300 | 30–60 | For compact designs |

| Monolithic | Custom | Custom | 50–100+ | Carved from a single block |

Standard Riser Heights

- Indoor: often regulated—150 to 175 mm per step. Typical target ~170 mm.

- Outdoor/landscape: can be from 150 to 180 mm. Lower risers (150 mm or less) in gardens for ease of access.

Customization Options Based on Site Needs

Thicker stone may be required to bridge the rough bases or stipulated lengths of landing stops. Special dimensions may be required by edge finishes or by mitigating building code requirements.

Tolerance Standards in Cutting & Installation

Best practice tolerances:

- ±2 mm in thickness

- ±3 mm in length or width

- A difference in levels of less than 2-3 mm between adjacent treads

- When misaligned beyond these tolerances, there could be visual or safety problems.

Stone Finishes for Treads and Risers

Natural Cleft

Suitable for sandstone or slate. Barbed and uneven feel. Bright, dry landscaped stairways of a rustic nature.

Flamed

It forms a rough texture on granite or quartzite. Very slip-resistant- outside stairs are the most favoured.

Honed

Even matte surface. Soft underfoot without being shiny. Frequently applied in entry zones or interiors due to safety.

Polished

Shiny, reflective, frequently in swanky interiors. Stands up to aesthetic test but can be slippery unless fashioned with nosing or mats.

Bush‑Hammered

Rounded, homogeneous, hammered texture. Provides a good grip. To be used on public outdoor stairs or pools.

Sandblasted

High-pressure fine-grit partially textured matte can be obtained by blowing. Not-slippery, mildly haptic anything near doorways and moist areas.

Tumbled

Soft, edge-rounded appearance. Unusual on treads because of the irregularity. It can be used in a rustic landscape.

Design and Aesthetic Considerations

Matching Tread and Riser Stone Colors

There can be variance in the stone’s colour between batches. Same quarry, same lot, as to cohesion. Mismatch is minimised by cutting treads and raising the adjacent stone.

Contrasting vs Blending Treads

- Contrasting: e.g. dark risers, light treads make the step lines visible.

- Blended/Monochrome: no visual clatter; smooth and elevated flow, particularly in contemporary structures.

Lighting Integration

- Light emitted by recessed tread lighting underneath the nosing conceals the source of light and provides safety.

- Step lights are built into the walls or stringer, and they highlight every step.

- Stair lights powered by solar energy can simplify the wiring and assembly process in outdoor stairs.

Edge Detailing for Safety and Style

Bullnose or rounded edges are smoother and impede chipping. Chamfers exclude sharpness and make the transitions softer. Ogee profiles are more decorative, but more expensive and more difficult to cut.

Texture for Traction and Appeal

- Outdoor Use: flamed, bush-hammered, or sandblasted gripping surfaces.

- Indoor Use: polished or slightly serrated surfaces. Polished may need anti-slippery tread strips or carpets.

Installation Methods and Tips

Site Preparation and Base Construction

- Excavate and compact soil.

- Gravel or crushed stone base with a depth of at least 100 mm and compacted.

- Pour a matt a concrete slab or a mortar bed levelled correctly.

- In the case of indoor stairs, vapour barriers or moisture management are required in case of a concrete slab.

Adhesive and Mortar Use

- Apply polymer-modified stone-rated thin-set mortar.

- In the case of heavy treads, spread the mortar, and back butter the treads.

- Floating or cantilever designs may require anchoring rods or stainless-steel clips.

Dry Laying vs Wet Laying

- Dry laying: fiddling, temporary placement, and fitting in the absence of mortar. Can be helpful initially, but can change.

- Wet laying: mortar grips treads. Most suitable when outdoor or heavy-traffic applications are involved.

Jointing and Grouting Techniques

- Leave a gap of 2-5mm between joints.

- Apply matching grout to the stone in colour.

- Flexible grout or colour-matched caulk should be used on the exterior joints that may expand.

- Tool and fill gaps solidly, and seal water penetration openings.

Tools Required for Installation

- Wet saw with a diamond blade

- Level (spirit or laser)

- Rubber mallet to seat treads

- Notched trowel, grout float

- Drill and anchors (cantilevered styles)

- Safety equipment: protective gloves, goggles, and a mask for cutting dust

Common Installation Mistakes to Avoid

- Base not levelled correctly- treads can drift or bounce.

- The installation of treads mixed into batches of random stone-namely, visible colour variance.

- Disregarding minor slope or drainage, which would cause water to pond.

- Outdoor stairs with polished stone and no traction.

- Floating stairs need to be finely engineered due to insecure anchorage.

- Over grouting or wide joints that retain water.

Maintenance and Durability

Cleaning Guidelines for Different Stone Types

- Indoors: Shear frequently, wash using pH-neutral stone polish.

- Outdoors: sponge and bring off lightly with the help of a soft-bristle brush.

- Acid cleaners, such as vinegar or lemon, etch limestone, travertine, and certain sandstones.

Sealing Stone Treads

- Seal porous stones (limestone, travertine, sandstone) are resealed in a period of 1-3 years; this depends on the level of use.

- Dense stones(granite, quartzite, bluestone). These may require less frequent sealing or even none, as long as they are not stained.

Preventing Slipperiness

- Finishes ought to be non-slippery outdoors, runner carpet indoors, suggesting on gripping pads.

- Use spray anti-slip coating or steps with textured strips in wet areas(pool/patio steps).

Weather Resistance and Seasonal Care

- In freeze-thaw regions, stonework should be low-porosity stone.

- Shovel snow early, always avoid the use of sharp chemical ice-melt around stone.

- Clean algae, mould, and lichen with the cleaners supplied by the manufacturer.

Repairing Chips and Cracks

- Put epoxy or resin in small chips matching the colour.

- When treads are cracked or damaged, they can be replaced as individual pieces.

- Steel edges can be refilled by professional kits, sanding patches can be repaired, and finishes can be applied to cover minor repairs.

Pros and Cons of Using Natural Stone for Stair Treads

Advantages

- Durability: materials, such as granite and quartzite, are durable.

- Aesthetic beauty: special veining and textures make every step unique.

- Finish set: very diverse, subtle, honed through to rustic flamed.

- Durability: stone stairways, when properly installed, will potentially last decades or generations- in most cases, they will add value to the resale.

Disadvantages

- Higher cost: materials and finishes are more expensive than wood, MDF, and tile.

- Weight and installation complexity: the big slabs need heavy labour, supporting structures, and skilled masons.

- Maintenance requirements: Some varieties of stone may require sealing; porous stones will stain.

- Slip hazard if poorly selected finish: polished floors can become slippery in outdoor or wet areas until they are matted or rugged.

Cost Considerations

Material Cost Comparison by Stone Type

- Granite: medium or above; higher grade varies by colour and source.

- Quartzite: generally more expensive than granite; more exotically veined adds to the price.

- Bluestone / Slate: mid-range; local stone is priced by region.

- Travertine and Limestone: medium price; inferior grades are cheaper.

- Sandstone: typically cheaper; rough color is less expensive, but it has an expensive sealed appearance.

Prices are highly variable depending on the region, thickness, finish, and complexity of design.

Installation Costs (DIY vs Professional)

| Approach | Pros | Cons |

| DIY | Save on labor costs | Requires skill, tools, and time |

| Professional | Expert finish and safety | Higher total cost |

Typical professional installation includes site prep, cutting, levelling, anchoring, joint sealing—roughly 40‑60% of project budget.

Long‑Term Value vs Initial Investment

Though the initial cost is greater than that of wood or tile, its longevity, classic look, and minimal long-term maintenance can make the cost incurred worth the product. Stone stairs are usually economical in the long run as they last longer by decades in comparison to other stair materials.

Sustainability and Eco-Friendliness

Natural Stone as a Green Building Material

- Inert, durable, and low-maintenance-requires less frequent replacement.

- Extremely little chemical treatment, particularly on stone quarried locally.

- More and more sustainable stone is being extracted in quarries that have responsible practices.

Locally Sourced Stones

- When sourced locally, transportation carbon emissions and costs are reduced.

- Promotes local quarries and economies.

- Local stone is likely to be compatible with local styles of architecture.

Recycling and Reuse Potential

- Use stone salvaged in deconstruction or remodel.

- We have old treads that can be used to make garden steps, edging, wall caps, or retention stone.

- Stone is completely inert and can be recycled an infinite number of times-no toxic waste upon removal.

Choosing the Right Stone for Your Stair Treads

Climate Compatibility

- Hot, dry climates: granite, quartzite, sandstone-UV resistant, arid-tolerant.

- Freeze–thaw environments: dense, hard stone, such as granite-water absorption is restrained.

- Poolside/mild climates: filling and sealing of travertine or limestone on the poolside provides a cool foot feel and a soft look.

Usage & Foot Traffic

- High‑traffic zones: use either granite or quartzite that are intrinsically textured (flamed, bush-hammered).

- Low‑traffic decorative stairs: lighter stone or finer finish can be allowed.

Budget and Aesthetic Preferences

- Polished marble-like finishes on quartzite or granite can be employed in premium interior use.

- In the case of rustic, natural gardens, use sandstone, cleft bluestone.

- Honed grey granite/quartzite gives a good finish to contemporary, minimalist floating steps.

Expert Recommendations and Samples

- Always request full-size or edge-cut samples.

- Visit installed projects or showrooms to feel the texture.

- Seek the installation recommendations of stonemasons, such as edge design and needed structural backing.

Inspiring Design Ideas and Use Cases

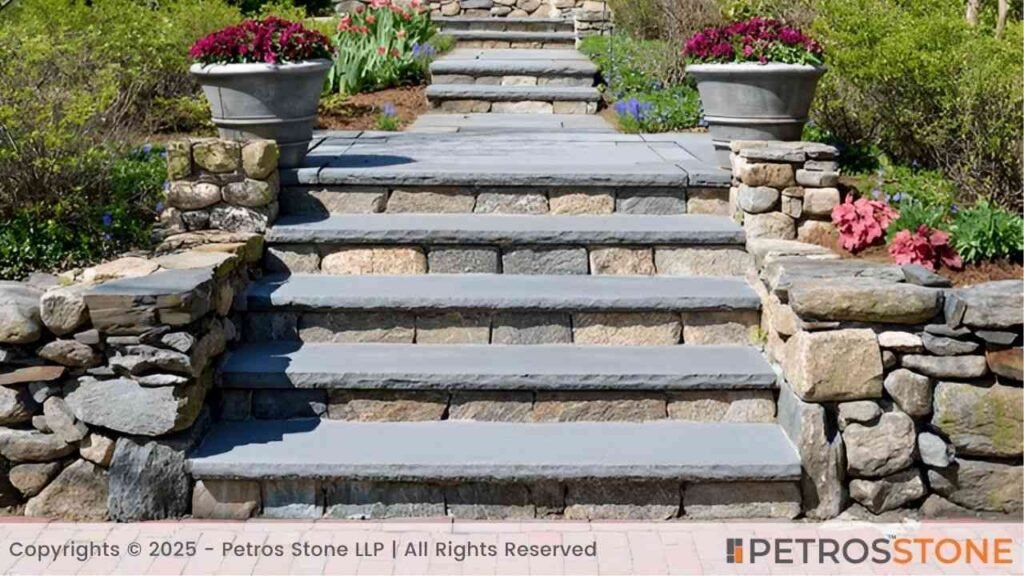

Traditional Outdoor Steps

Flamed finish granite or bluestone with bullnose edges, shallow risers, and wide treads. Simple, yet secure, they were perfect to use in the entrance to a garden or on the front steps.

Contemporary Indoor Floating Stone Treads

Invisible in-wall or steel stringer-mounted treads in honed quartzite or granite, slim profile. Lighted underneath, spotless, smooth-looking architectural statement.

Garden Steps with Integrated Greenery

Sandstone or slate treads interleaved with planting strips—moss, thyme, or creeping groundcover between steps. Organic feel and natural pathway blend into the landscape.

Rustic Farmhouse Entry Stairs

Raw-cut sandstone or bluestone treads with bush-hammered or split-face finish. Aged appearance, combined with stone walls or wooden railings that have been repurposed.

Zen‑Inspired Landscape Paths

- Big flat stone plates in a minimal design over gravel/ grass. Low-rising and tapetrack edges remind one of mindfulness walking in meditation gardens.

- The applications made use of variations in form and functionality in various settings, such as residential, public, decorative, and functional.

Summary

We have discussed every detail of the natural stone stair treads in this guide: the terminology of stair treads, the types of stone, the design options, the sizes, the finishes, the installation details, the maintenance of the staircase, the cost, the sustainability factor and all other creative ways available to make your staircase elegant and worth it.

A beautiful stone staircase is the perfect blend of aesthetics and durability in equal measure; properly planned, carefully designed, and installed, it lasts a lifetime and can pay off for the homeowners and designers through generations.

Granite, quartzite, limestone or bluestone are some of the choices that provide texture and colour options that complement your climate, your use, and vision.

Key Takeaways

- Natural landscapes have diverse options of materials such as granite, bluestone, limestone, and quartzite as natural stone stair treads, which are available in distinctive textures and colours.

- The styles of design include freestanding solid block stairs, cantilevered or floating designs, which are appropriate both inside and outside.

- Flamed, honed, or tumbled finishes provide increased safety, traction, and aesthetics.

- The longevity/safety must be achieved through proper installation, i.e., base preparation, edge treatment, and sealing.

- Although costly, natural stone staircases are durable and environmentally friendly, and increase the long-term value of any property.

Feel free to get in touch for a free consultation, quote, and get a detailed understanding from our experts here at Petros®. Visit https://petrosstone.com/ or call +91-8446360361 and WhatsApp

Hello!

I’m Dr Mridali, a content writer with a background in dentistry and a passion for turning complex topics into clear, engaging stories. From healthcare to architecture, I create blogs that inform, educate, and connect with readers. With every piece, I aim to blend accuracy with creativity to make information truly valuable.

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite