Quartz slabs are manufactured in a factory, which means that the companies have control over its aesthetic and physical qualities.

However, not all quartz slabs are of the same quality – there are many grades, brands and in this article, we are going to explore some measures that you should be aware of before buying a quartz slab.

To ensure you are investing in a good quality quartz slab, here’s a guide on how to check the quality of quartz slabs.

- Understanding Different Grades of Quartz Slabs

- How to Test Quartz Slab Quality?

- Applications of Quartz Slabs Based on Grades

- Good-Quality Quartz Slabs Vs Bad-Quality Quartz Slabs

- Where to Buy High-Quality Quartz Slabs?

- Importance of Warranty Coverage

- What to Expect in After-Sales Service?

- Key Factors to Consider When Buying Quartz Slabs

- Checklist Quartz Quality Inspection

- Need Help Inspecting Quartz Slabs?

Understanding Different Grades of Quartz Slabs

Quartz slabs come in various grades, primarily categorized into:

1. Commercial-Grade Quartz

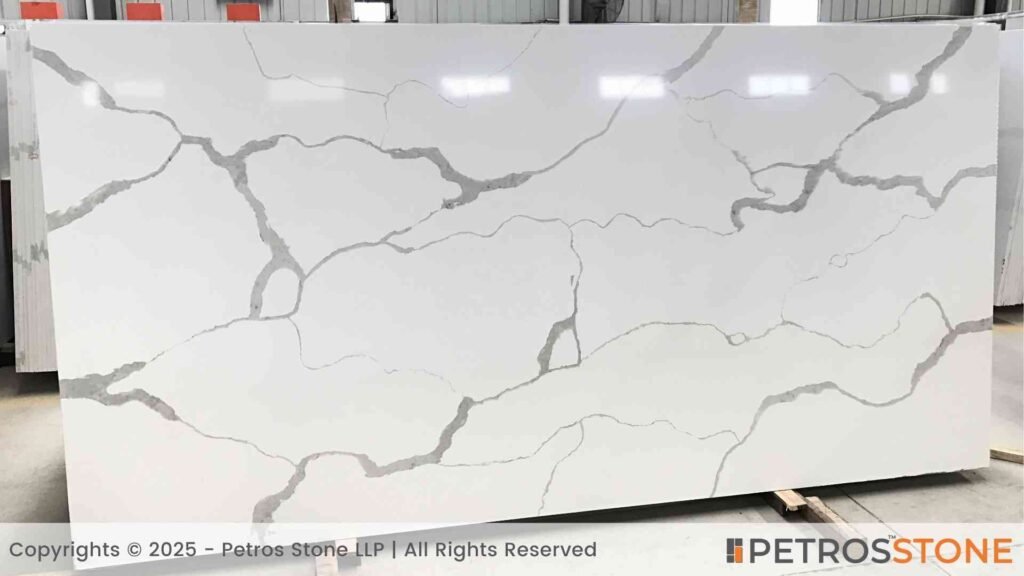

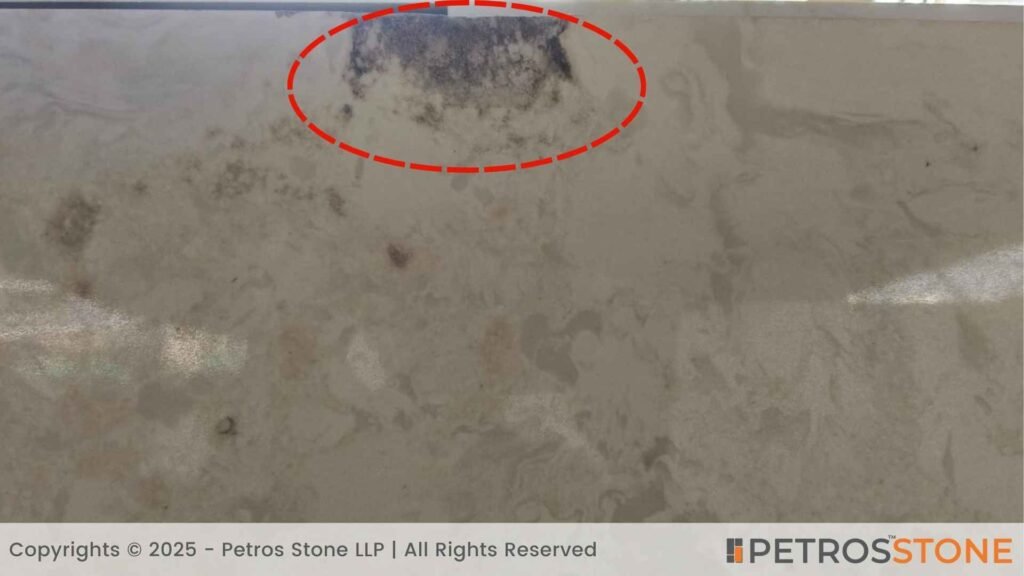

Typically contains more resin and fewer natural quartz crystals, making it less durable. This grade is often used in low-budget projects where cost is a major factor. It may also contain black dots and defects as indicated in the photo below.

Due to the high resin content, commercial-grade quartz is more prone to scratches, stains, and discoloration. While it may have a visually appealing finish, its longevity and performance are significantly lower than higher-grade quartz.

It is best suited for commercial and low cost projects.

2. Standard-Grade Quartz

These quartzes are high quality quartz slabs with minor aesthetic or physical defects – such as small pin holes, black dots or unpleasant aesthetic patterns.

This type of quartz is usually preferred by independent fabricators who can cut and fabricate around these issues making sure the final product is defect free as much as possible and at the same time offering an affordable price.

Standard-grade quartz is a practical choice for homeowners looking for a cost-effective yet reliable option – but you must be aware of this before you make a decision.

We will discuss how you can spot different grades of slabs a little later on.

3. Premium-Grade Quartz

High quartz content (90% or more), uniform consistency, and superior durability, often used in high-end projects. This grade is designed for high-traffic areas and luxury applications, offering excellent resistance to scratches, stains, and heat.

The high quartz content ensures a firm, dense slab that can withstand heavy use without showing signs of wear and tear. Premium-grade quartz also features superior pattern consistency and colour uniformity, making it ideal for upscale kitchens, commercial spaces, and premium flooring installations.

Though more expensive, it provides long-term value due to its exceptional durability and minimal maintenance requirements.

How to Test Quartz Slab Quality?

Quartz slabs are a popular choice for countertops, flooring, and wall cladding due to their durability, aesthetic appeal, and resistance to scratches and stains. However, not all quartz slabs are of the same quality. To ensure you are purchasing a high-quality slab, you can perform a series of visual inspections and use specific tools to assess its consistency, strength, and finish

1. Visual Inspection for Defects

A high-quality quartz slab should have a uniform pattern, consistent color, and a smooth surface. During the inspection, look for:

- Pattern Irregularities: Check if the veining or design flows smoothly across the slab. Poor-quality slabs may have abrupt changes in the pattern or inconsistencies.

- Black Spots or Pinholes: Tiny black spots or air pockets can indicate manufacturing defects. A premium slab should have minimal or no visible imperfections.

- Color Consistency: The shade of the slab should be uniform throughout. If there are noticeable variations, it may indicate poor-quality resin or improper manufacturing.

2. Thickness Test Using Vernier Caliper

Quartz slabs typically come in standard thicknesses such as 12mm, 15mm, 20mm, or 30mm. Use a vernier caliper to measure the slab’s thickness at different points. This helps ensure that:

- The thickness is consistent across the slab.

- There are no thin or uneven areas, which could indicate manufacturing flaws.

- The slab meets the industry-standard thickness for durability.

3. Surface Smoothness Test – Spotting Microcracks

Run your hand across the entire slab surface to detect any microcracks, rough areas, or uneven textures.

- Smooth and even surface: Indicates a well-polished, high-quality slab.

- Rough patches or tiny cracks: Could mean the slab has structural weaknesses, which may cause it to break easily.

4. Consistency in Thickness – Measuring Different Sides

To further verify uniformity, measure the thickness of the slab at different edges and corners.

Uneven slabs may cause installation issues and durability concerns.

If there is a variation in thickness, it could suggest improper cutting or uneven compression during manufacturing.

5. Checking for Bends or Warping

A high-quality quartz slab should be perfectly flat. You can check this by:

- Eye Inspection: Look along the edges of the slab to see if there is any noticeable bending or warping.

- Spirit Level Test: Place a spirit level or straight edge on different parts of the slab to confirm it is flat and even.

Bends in the slab can make installation difficult and may lead to cracks over time.

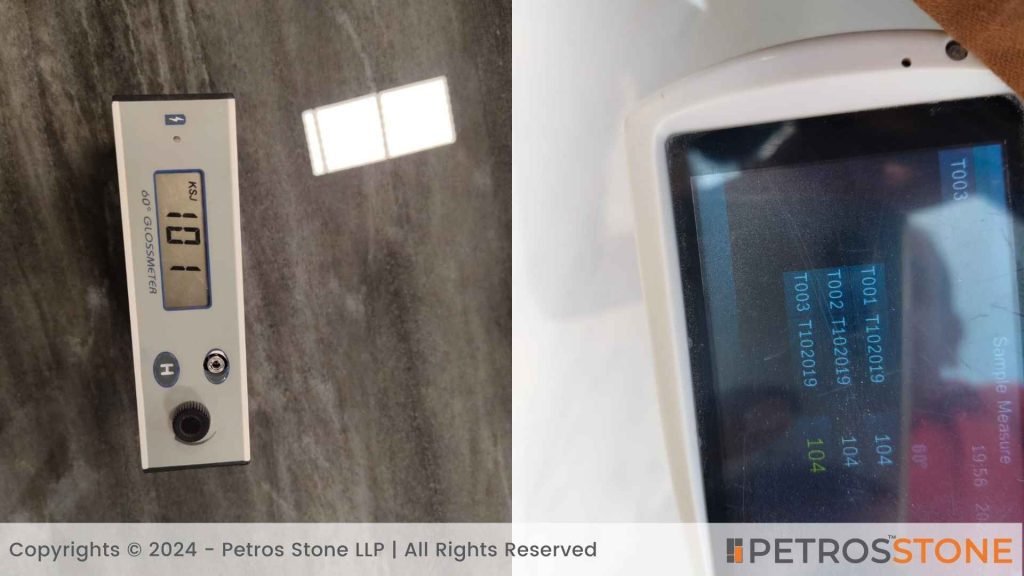

6. Glossiness and Polish Quality Test

Quartz slabs should have a high gloss level, reflecting their premium finish. You can test this using a gloss meter, which measures the reflectivity of the surface.

- High-quality slabs have a gloss reading of above 80 GU (Gloss Units).

- If the gloss level is lower, the slab may not have been polished properly or might contain low-quality resins.

7. Certification and Third-Party Testing

To ensure you are getting a genuine and high-quality quartz slab, always check for certifications from reliable third-party inspection bodies.

- Certifications from ISO, SGS, NSF, or Greenguard indicate that the slab meets industry standards for safety and durability.

- Always ask for manufacturer documentation and batch testing reports for added assurance.

Applications of Quartz Slabs Based on Grades

Quartz slabs are used in a variety of applications depending on their grade. Understanding their best-suited applications helps in selecting the right slab for durability, performance, and aesthetic appeal.

1. Commercial-Grade Quartz Slabs

- Used in budget-friendly residential or commercial projects where high durability is not a primary concern.

- Suitable for low-traffic areas, such as decorative wall panels, office reception desks, and retail countertops.

- Commonly used in rental properties where cost-effectiveness is prioritised over longevity.

- Can be found in temporary installations where appearance is needed but durability is not critical.

2. Standard-Grade Quartz Slabs

- Ideal for residential kitchens, offering a balance between affordability and durability.

- Commonly used for bathroom vanities, as it withstands moderate moisture exposure.

- Suitable for backsplashes and wall cladding in homes due to its moderate strength and stain resistance.

- Often installed in apartment kitchens and mid-range hotels, where aesthetics matter but high-end durability isn’t required.

3. Premium-Grade Quartz Slabs

- Best for high-traffic areas such as luxury hotels, upscale restaurants, and commercial flooring.

- Perfect for luxury kitchen countertops in premium homes, offering superior durability and elegance.

- Used in commercial office spaces, including boardroom tables, reception desks, and lobby areas.

- Ideal for medical and laboratory settings, where non-porous, hygienic surfaces are essential.

- Suitable for outdoor applications (if UV-resistant) in high-end outdoor kitchens and patios.

Good-Quality Quartz Slabs Vs Bad-Quality Quartz Slabs

1. Composition and Resin Quality

- A high-quality quartz slab contains 90–95% natural quartz and 5–10% resin.

- Lower-quality slabs have higher resin content, reducing durability and increasing susceptibility to damage.

2. Stain Resistance

- High-quality quartz is non-porous and resists stains from wine, coffee, and other everyday spills.

- Subpar quartz may absorb stains over time, leading to discoloration.

- To learn more about quartz stain resistance properties, Read This Article

3. Scratch and Impact Resistance

- Premium quartz is highly scratch-resistant and can withstand daily wear and tear.

- Poor-quality quartz may show scratches and chips more easily.

4. Heat Resistance

- A good-quality slab should withstand moderate heat exposure without damage.

- Inferior quartz can develop burn marks when exposed to hot pans.

5. Weight and Density

- Higher quartz content results in a heavier, denser slab with better durability.

- Low-quality quartz feels lighter and may have air pockets or weak spots.

- Use this tool to calculate the weight of any stone.

6. Thickness and Consistency

- The standard thickness for quality quartz slabs is 12mm, 15mm, or 20mm.

- Poor-quality quartz may have inconsistent thickness, making installation difficult.

7. Pattern and Colour Consistency

- Authentic quartz slabs have uniform patterns and colours throughout.

- Inferior slabs may show unnatural variations, fading, or discoloration.

8. Flexibility and Bending

- High-quality quartz remains rigid and does not bend under pressure.

- Poor slabs may flex, indicating weak composition.

9. Resin Percentage and Transparency

- Too much resin can make the slab look artificial and plasticky.

- High-end quartz maintains a natural, stone-like appearance.

10. Presence of Artificial Enhancements

- Some low-quality quartz slabs are coated with artificial gloss to enhance appeal.

- Genuine quartz does not require additional surface treatments.

Where to Buy High-Quality Quartz Slabs?

Quartz slabs are popular for countertops, flooring, and wall cladding due to their durability, low maintenance, and aesthetic appeal. However, purchasing high-quality quartz requires careful consideration to ensure you get a product that meets your expectations in terms of appearance, longevity, and performance. Below are the best places to buy high-quality quartz slabs and factors to keep in mind while purchasing.

1. Authorized Dealers & Showrooms

Buying from official showrooms ensures you get genuine, certified quartz slabs from top brands like Caesarstone, Silestone, Cambria, and MSI.

- Genuine products with warranties

- See and feel slabs before purchasing

- Expert guidance on installation and maintenance

Tip: Visit multiple showrooms to compare colors and finishes

2. Reputable Suppliers & Fabricators

Local suppliers and fabricators provide a variety of brands and customization options, including edge profiles and cut-outs.

- Diverse slab selection

- Customization and professional installation

- Proven quality through previous projects

Tip: Check references or past work before finalizing a supplier

3. Home Improvement & Hardware Stores

Retailers like Home Depot, Lowe’s, and Bunnings offer quartz slabs at competitive prices to homeowners and contractors.

- Wide selection of brands

- Occasional discounts and promotions

- In-store assistance for selection

Tip: Review return policies and warranties before purchasing.

4. Online Marketplaces & Retailers

E-commerce platforms like Amazon, Wayfair, and specialty stone retailers provide a vast selection of quartz slabs.

- Convenient shopping from home

- Customer reviews for quality insights

- Access to various brands and styles

Tip: Order a sample first to check color and texture in person.

5. Wholesale Distributors

For bulk purchases, wholesalers offer cost-effective options for contractors, designers, and builders.

- Lower prices for large orders

- Extensive color and pattern choices

- Ideal for commercial projects

Tip: Verify the distributor’s reputation and quality assurance policies.

Importance of Warranty Coverage

A warranty safeguards your quartz slab investment against defects, discoloration, and structural issues. Top manufacturers offer warranties from 10 years to a lifetime, ensuring long-term protection.

A good warranty should cover:

- Material defects – Cracks, chips, and inconsistencies

- Color consistency – Maintains original appearance

- Structural integrity – Fabrication and installation issues

- Stain resistance – Protection against spills

Always review terms, exclusions, and claim processes to make an informed decision.

What to Expect in After-Sales Service?

After-sales service plays a significant role in maintaining the quality and longevity of quartz slabs. A reputable manufacturer or supplier will offer comprehensive customer support beyond the purchase, including:

- Installation Assistance – Many suppliers provide guidance or certified professionals to ensure proper installation.

- Maintenance Support – Instructions on cleaning, sealing, and preventing damage to prolong the lifespan of the slabs.

- Repair and Replacement Services – Support for minor damages, including scratch and chip repairs or full slab replacements if needed.

- Customer Care Helpline – A dedicated service team to address queries and concerns related to product performance and care.

- Inspection Services – Periodic quality checks to assess wear and tear, ensuring the quartz slabs remain in optimal condition.

Choosing a supplier with a strong after-sales support system enhances customer satisfaction and ensures that quartz slabs retain their beauty and durability for years to come. Always verify the warranty details and support services before making a purchase to maximize your investment.

Key Factors to Consider When Buying Quartz Slabs

Regardless of where you purchase your quartz slabs, consider these critical factors:

- Brand Reputation: Choose well-known brands for quality assurance.

- Slab Thickness: Quartz slabs typically come in 12mm, 20mm, and 30mm thicknesses. Select the right one based on your project needs.

- Colour & Pattern Consistency: Inspect multiple slabs to ensure uniformity.

- Surface Finish: Matte, polished, and textured finishes offer different aesthetics and maintenance levels.

- Warranty & Return Policy: Always check manufacturer warranties and return policies before purchasing.

Checklist Quartz Quality Inspection

| Quality Check Factor | High-Quality Quartz | Low-Quality Quartz |

| Quartz Content | 90% or more | Less than 80% |

| Resin Content | 5-10% | Over 20% |

| Stain Resistance | Highly resistant | Absorbs stains |

| Scratch Resistance | Highly scratch-resistant | Prone to scratches |

| Heat Resistance | It can withstand moderate heat | Easily damaged by heat |

| Weight | Heavy and dense | Light and fragile |

| Thickness Consistency | Uniform | Inconsistent |

| Pattern & Colour | Consistent | Unnatural variations |

| Bending/Flexibility | Rigid | Can bend |

| Artificial Enhancements | None required | Gloss coatings used |

Need Help Inspecting Quartz Slabs?

When selecting quartz slabs, it’s essential to conduct thorough quality checks, including tests for stains, scratches, heat resistance, and weight. Always choose a premium-grade quartz slab with high natural quartz content, consistent thickness, and a natural look to ensure durability and longevity in your projects.

Feel free to get in touch for a free consultation, quote, and get a detailed understanding from our experts here at Petros®. Visit https://petrosstone.com/ or call +91-8446360361 and WhatsApp

Hi, I’m Khushbu,

With years of experience in the field of architecture, I’ve developed a deep appreciation for the impact of natural materials in design. At Petros® Stone, I write to share my perspective on how stone can modernize spaces with beauty, function, and timelessness.

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite