Stone Quality Control

Stone Quality Control & Inspection at Petros® Stone

At Petros® Stone, we take pride in delivering high-quality natural and engineered stones that meet the highest industry standards. Our rigorous quality control (QC) process ensures that every slab, tile, and cut-to-size stone piece maintains exceptional durability, aesthetics, and precision. From raw material selection to the final inspection, we implement stringent quality checks to provide our customers with flawless and long-lasting stone solutions.

Quality Control Steps

How Our Quality Control & Inspection Works for Each Product

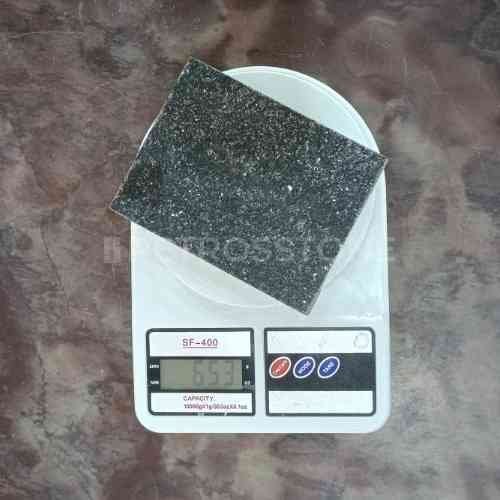

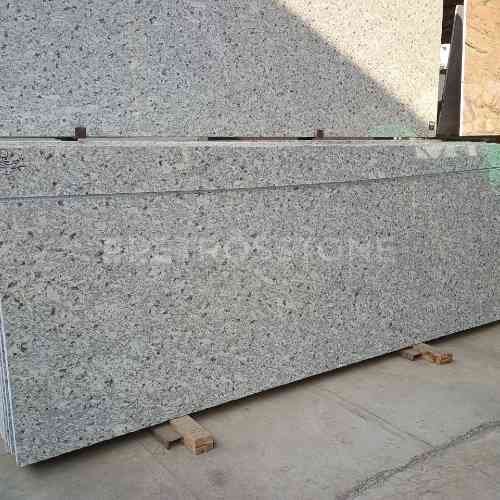

Natural Stones (Granite, Marble, Sandstone, Quartzite, Slate, Limestone)

- Block Selection & Cutting: Only premium-grade blocks are chosen, ensuring uniformity in color, pattern, and structural integrity.

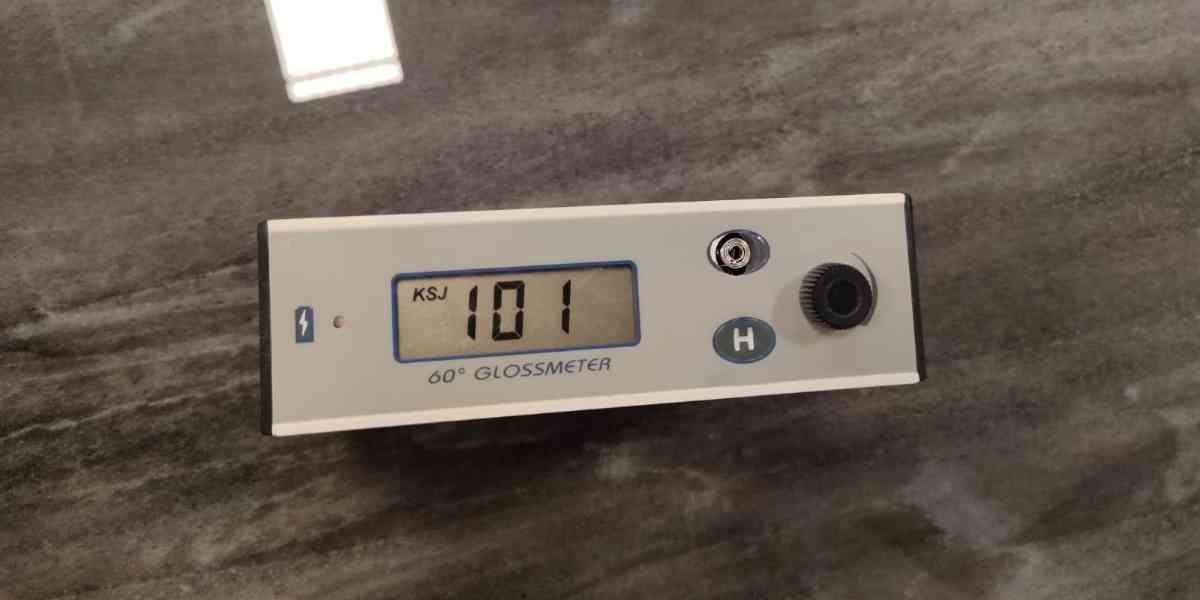

- Surface Polishing & Finishing: Each slab undergoes precision polishing and resin treatment for enhanced strength and a flawless surface.

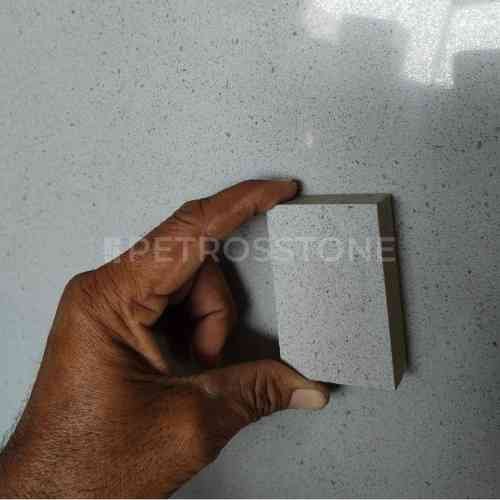

- Thickness & Dimension Accuracy: We use high-precision measuring tools to maintain uniform thickness and dimensional consistency.

- Crack & Imperfection Inspection: Any slab with natural flaws beyond the acceptable tolerance is discarded or reinforced with resin treatment.

Engineered Stones (Quartz, Porcelain, Sintered Stone)

- Raw Material Testing: The composition of quartz, resin, and pigments is tested for consistency and performance.

- Compression & Curing Checks: Advanced machinery ensures even compaction, preventing internal voids or weaknesses.

- Polishing & Edge Profiling: Automated polishers enhance the surface shine, while CNC machines craft seamless edge finishes.

- Water Absorption & Stain Resistance Tests: All engineered stones undergo lab testing to validate their non-porous nature and resistance to stains.

Engineered Stones (Quartz, Porcelain, Sintered Stone)

- Raw Material Testing: The composition of quartz, resin, and pigments is tested for consistency and performance.

- Compression & Curing Checks: Advanced machinery ensures even compaction, preventing internal voids or weaknesses.

- Polishing & Edge Profiling: Automated polishers enhance the surface shine, while CNC machines craft seamless edge finishes.

- Water Absorption & Stain Resistance Tests: All engineered stones undergo lab testing to validate their non-porous nature and resistance to stains.

Custom Stone Fabrication (Cut-to-Size & Prefabs)

- Precision Cutting & CNC Profiling: Each piece is cut with millimeter precision to match architectural specifications.

- Hand Finishing & Detailing: Skilled craftsmen refine the final edges and textures to ensure perfect detailing.

- Final Quality Inspection: A comprehensive final check ensures no surface defects, cracks, or inconsistencies before shipping.

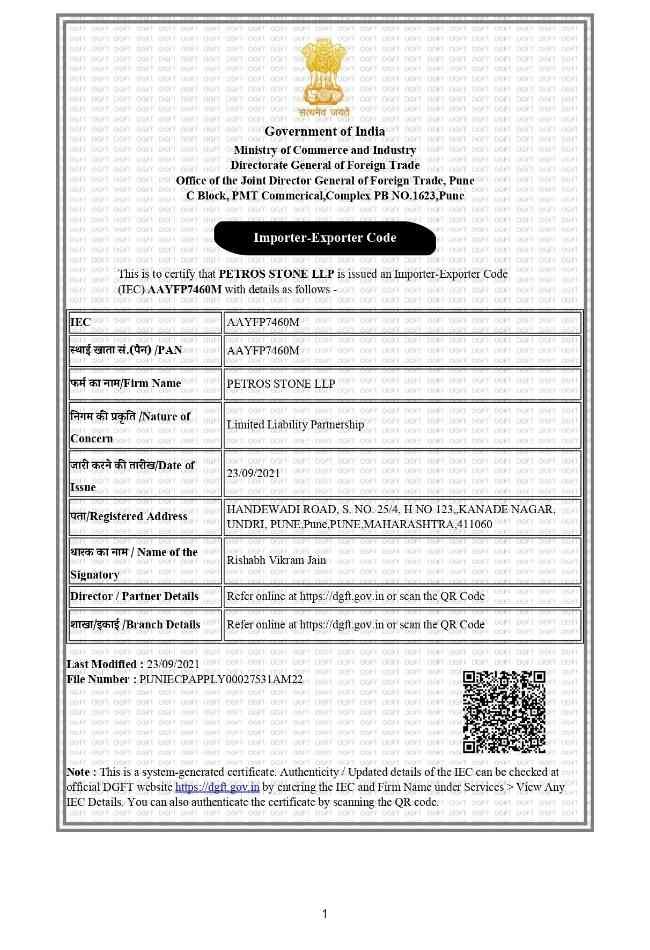

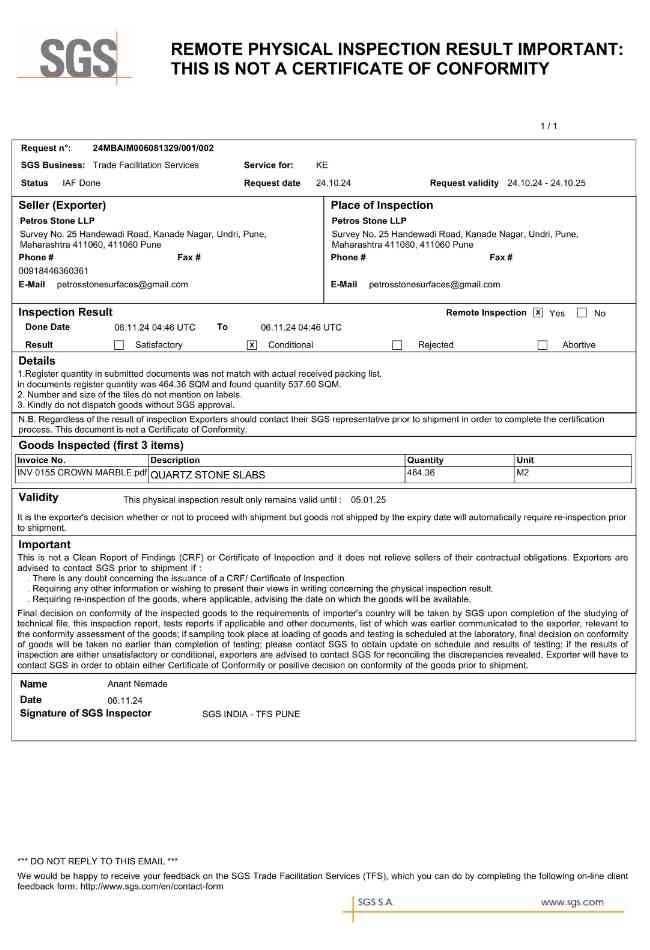

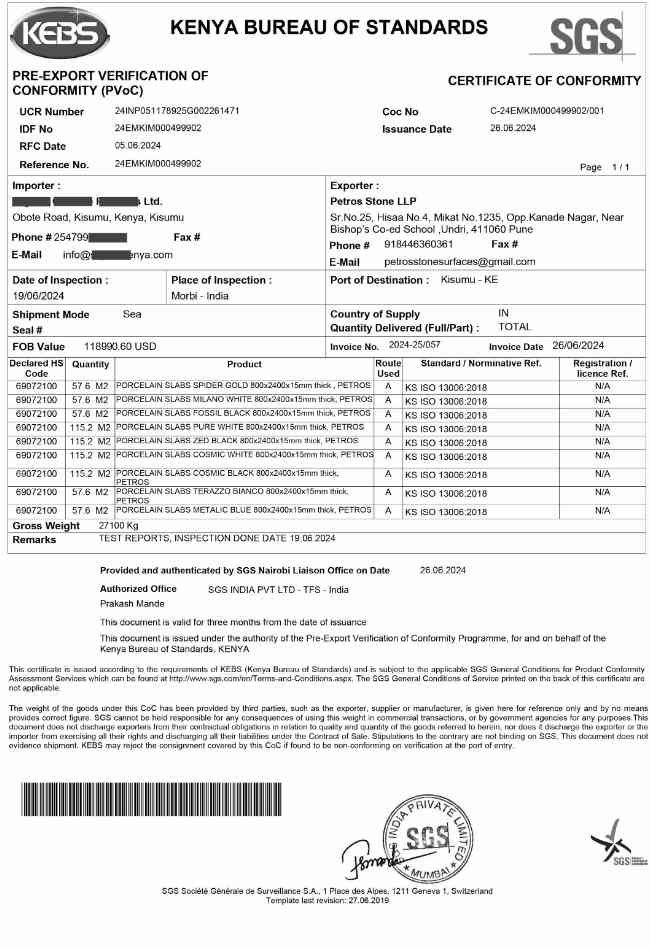

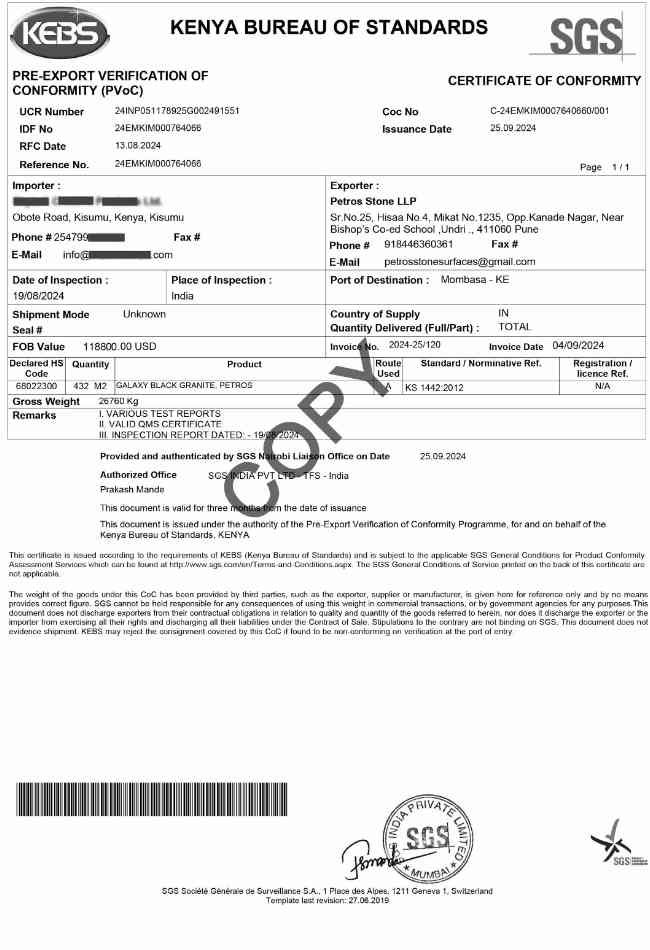

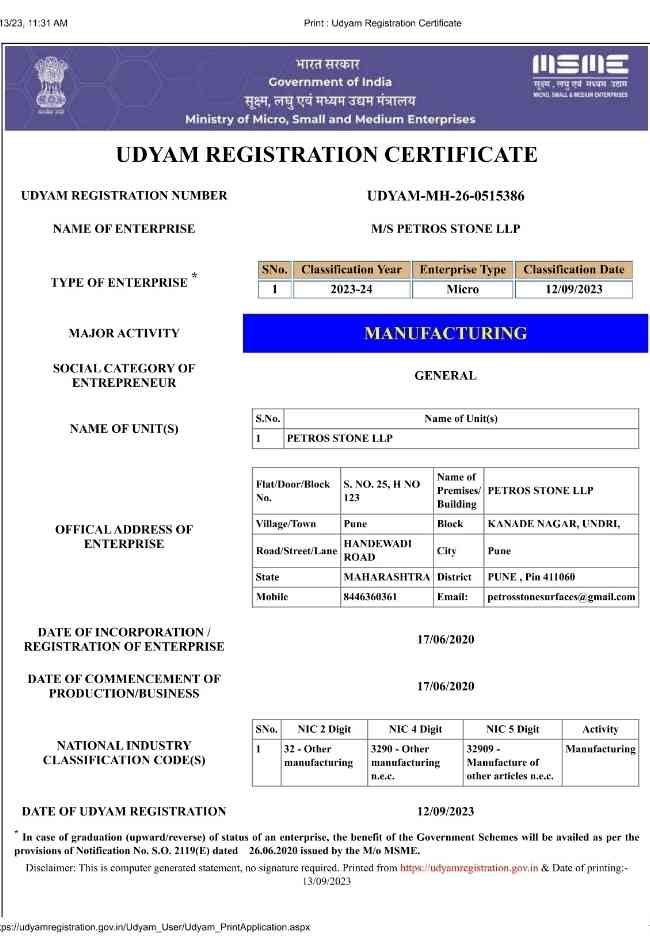

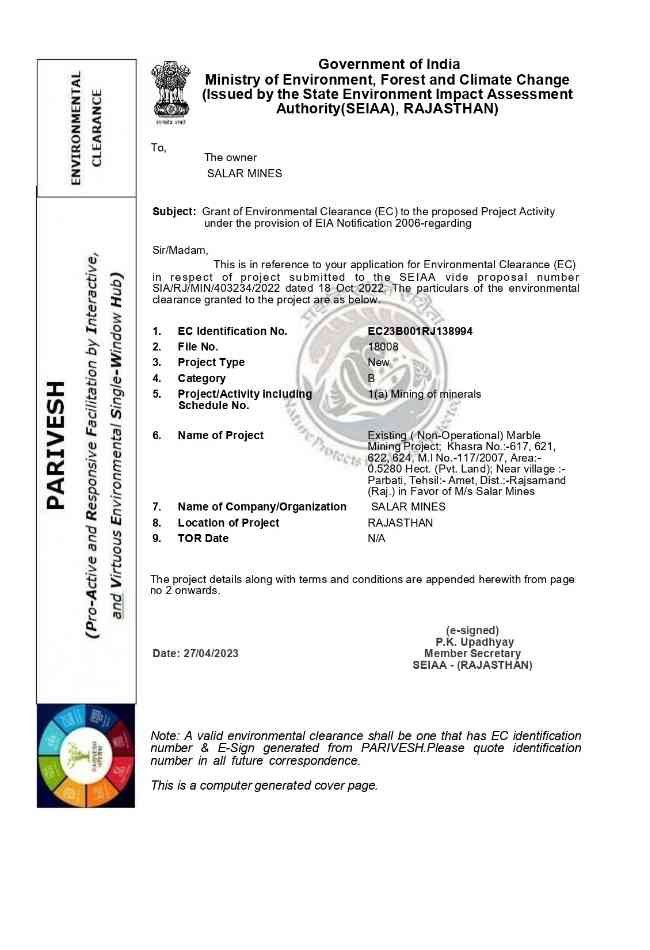

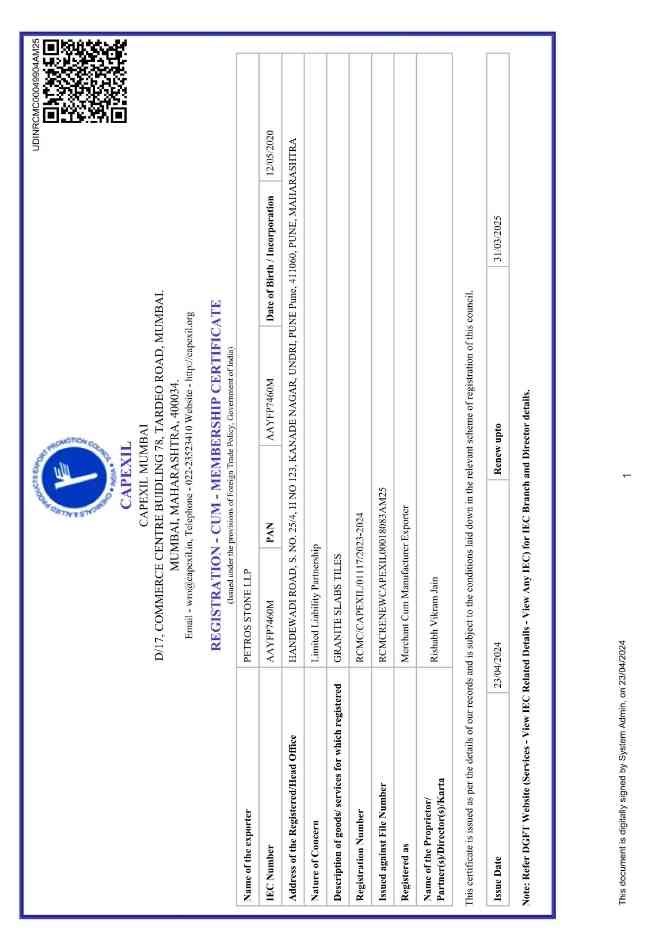

Certification