In this article we will look at several ways in which you can check and inspect the quality of granite – this will tremendously help you in the buying decision.

There is an increasing demand for granite at all levels—local, national, and international. However, imagine investing your time, energy, and funds in granite or marble for your new kitchen countertops or flooring, merely to discover that it chips instantly or stains with every spill. Sounds frustrating, doesn’t it?

This is the reason why granite quality testing is so critical.

Nevertheless, how can you determine whether the granite quality is genuinely superior? It is essential to conduct tests on granites and other natural stones to guarantee their quality, durability, and suitability for a variety of applications.

The following are some of the most frequently performed easy tests on granites and other natural stones:

- How to Check the Quality of Granite/Marble

- Primary Factors Affecting Granite Grade:

- How to Accurately Measure the Area of Granite Slabs?

- How to Measure the Thickness of Granite?

- How to Evaluate the Consistency of Granite/Quartz Thickness?

- How do we Measure the Polish Quality of Granite Slabs?

- How to Check if the Marble Slabs have Cracks?

- Visual Examination of Cracks in Natural Stone

- How do you Measure the Weight of Granite Slabs?

- Density of Granite Slabs

- What is the appropriate method for examining the bends in granite slabs?

- How to Check if Granite Slabs have any Artificial Coloring?

- Additional Quality Tests for a Granite/Marble Slab

- Conclusion

How to Check the Quality of Granite/Marble

Before understanding the different types of tests to determine the quality of granite or marble, one needs to know about the various grades of marble/granite.

In order to facilitate the differentiation of high-quality granite from entry-level granite, a grading convention has been established. Although some suppliers may employ additional classifications or levels, the following three are the most frequently used ones:

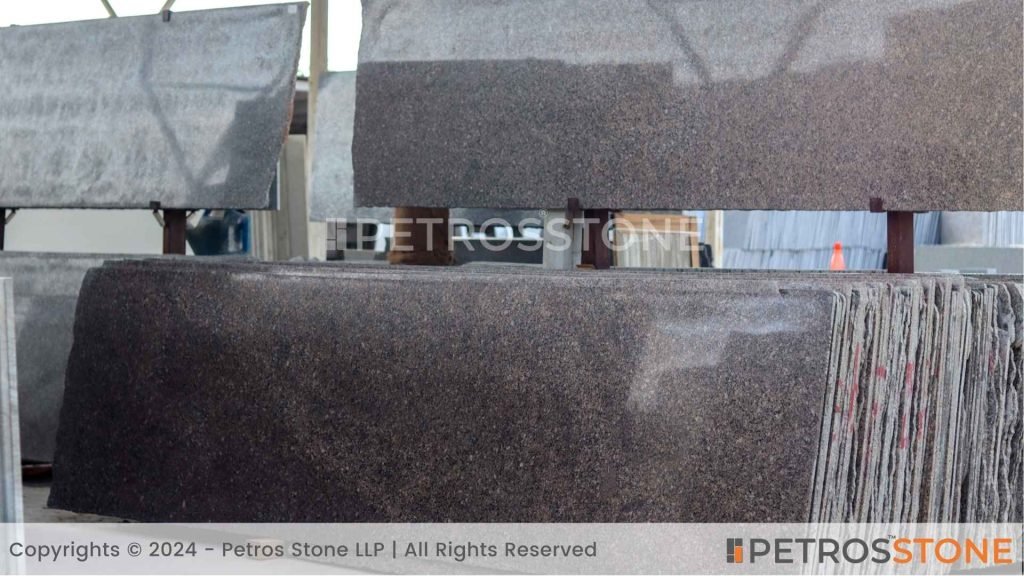

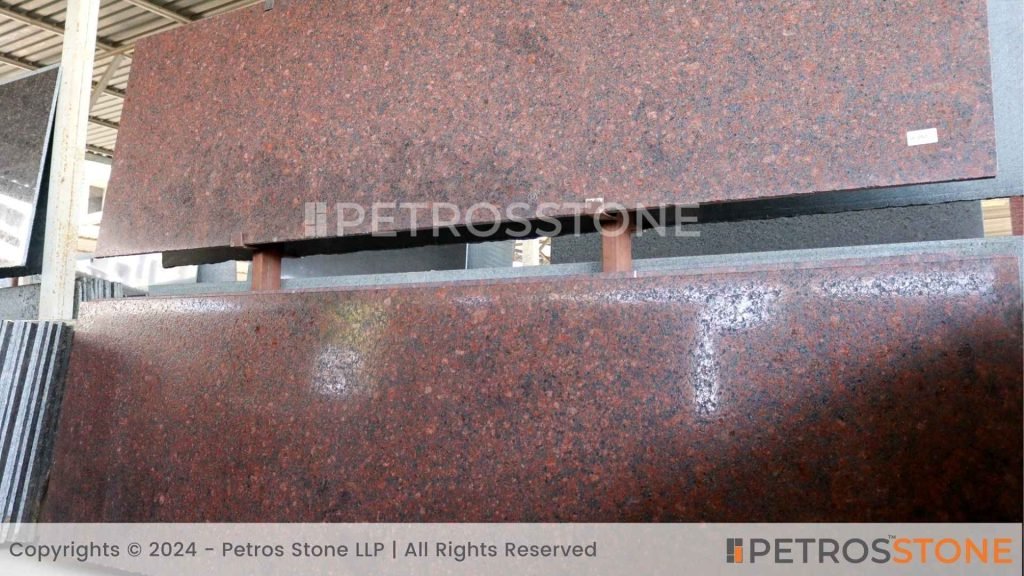

Grade 1: Entry-Level (Commercial or Builder)

• These are entry level granites with simple shades and simple patterns.

• These usually consist of granites such as G66, Tan Brown, and Desert brown and so on.

• These can be easily recognized as old granites from back in the day.

• These granites are now quickly running out of fashion for newer homes and most projects.

• However, they still remain viable options for budget large scale buildings and projects.

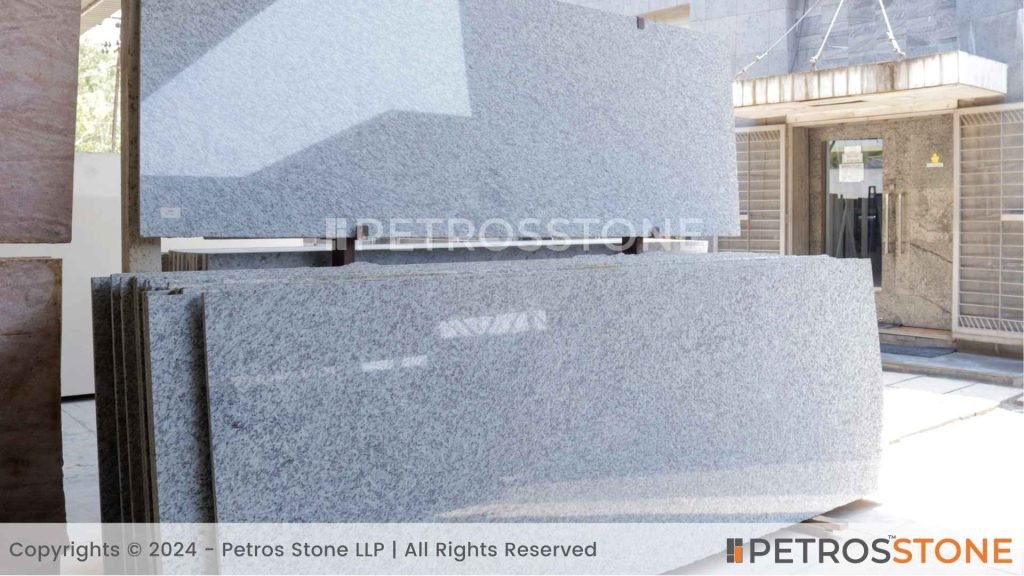

Grade 2: Intermediate

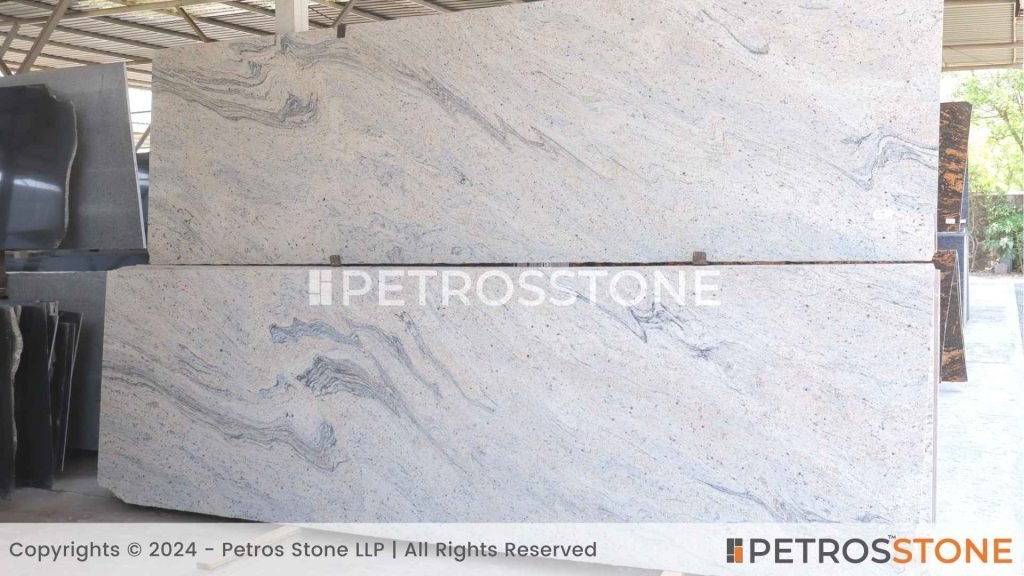

• Middle-grade Granite exhibits a greater variety of hues and patterns.

• Additionally, their markings exhibit a greater degree of diversity.

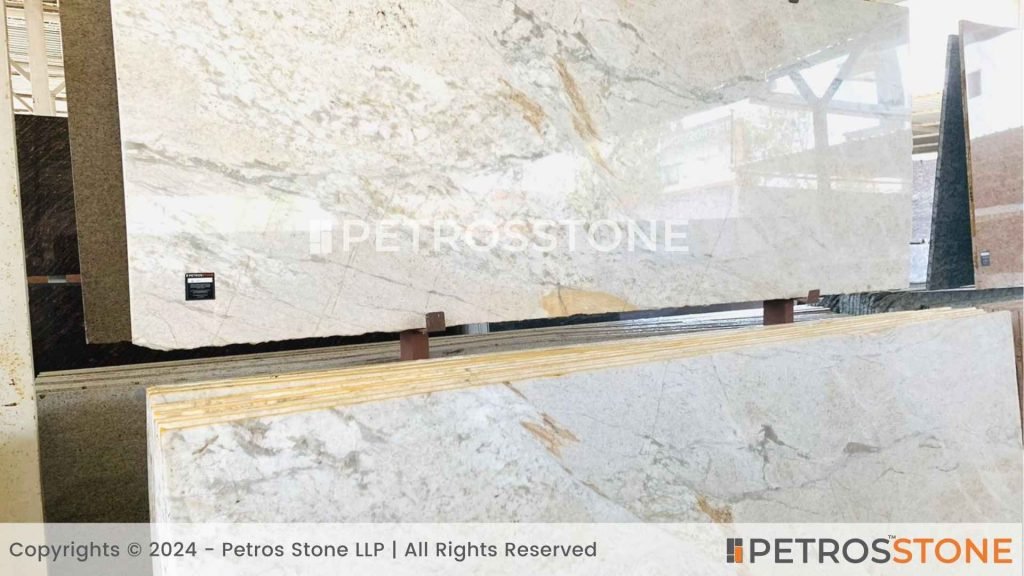

• They are sold as thicker slabs and are comparatively more durable and hard varieties of granite. Examples would be like the Sapphire Blue granite, the Vicon White Granite or the forest black granite.

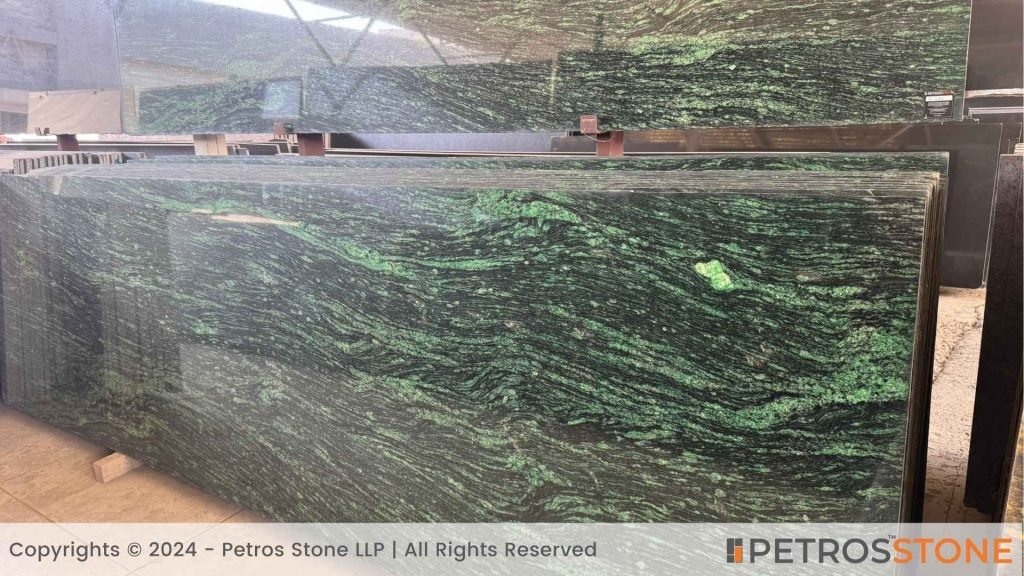

Grade 3: Advanced

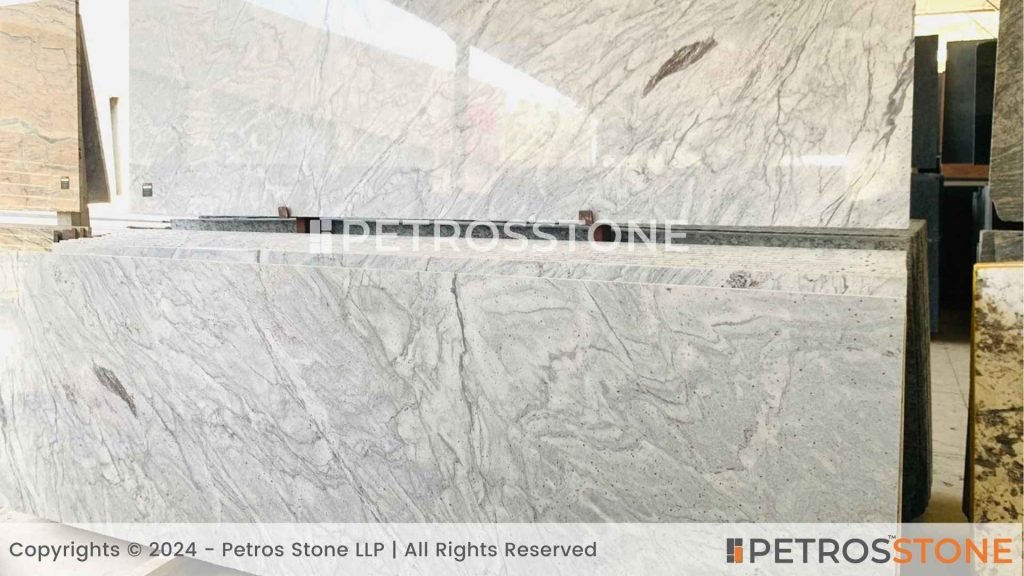

• This granite is of the highest quality in the collection. The designs are uncommon and may display veins and patterns, rendering them unique.

• The price of high-quality granite is determined by the presence of dazzling and glittering mineral deposits that create an additional visual appeal.

• These includes granites like the Armani Gold granite, Prada gold granite, the colonial white granite and so on.

Primary Factors Affecting Granite Grade:

1. Visual appearance: Colors that are uncommon and have striking veining are generally assigned higher grades. Lower grades may be assigned to colors that are consistent and widespread. The presence of fissures, pits, or excessive mineral deposits may reduce the grade.

2. Thickness: Slabs that are thinner in thickness may be classified as lower-grade, necessitating plywood support.

3. Porosity: Highly porous granite necessitates more frequent sealing and may be classified as a lesser grade.

How to Accurately Measure the Area of Granite Slabs?

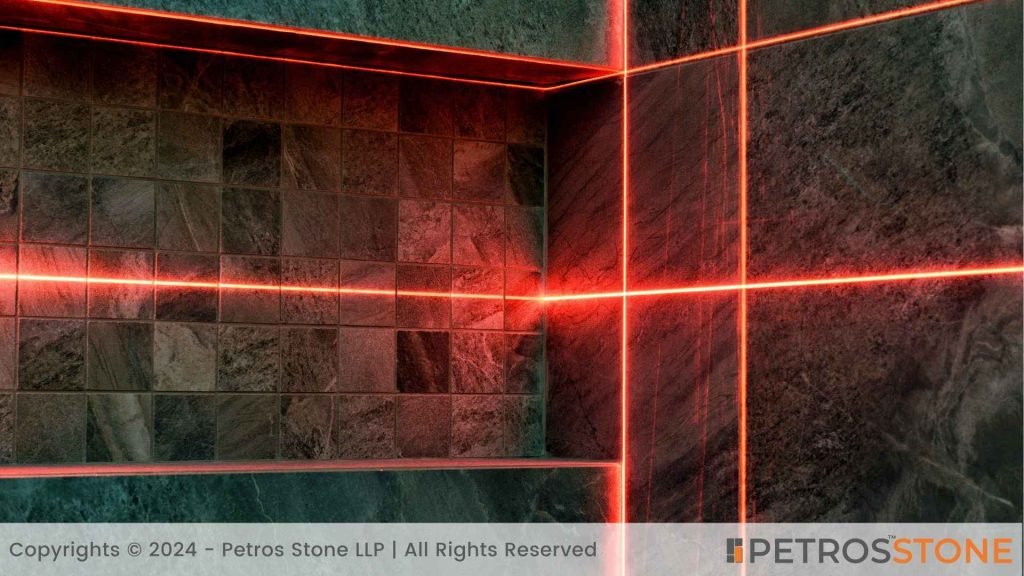

Laser Measurement

Accuracy can be improved, particularly for larger sections, by employing a laser measuring device. Position the laser at one end of the slab. To obtain precise measurements of both length and breadth, direct the laser to the opposite end. Please take note of these dimensions, as they will be essential for the area calculation.

Right Angled Measurements

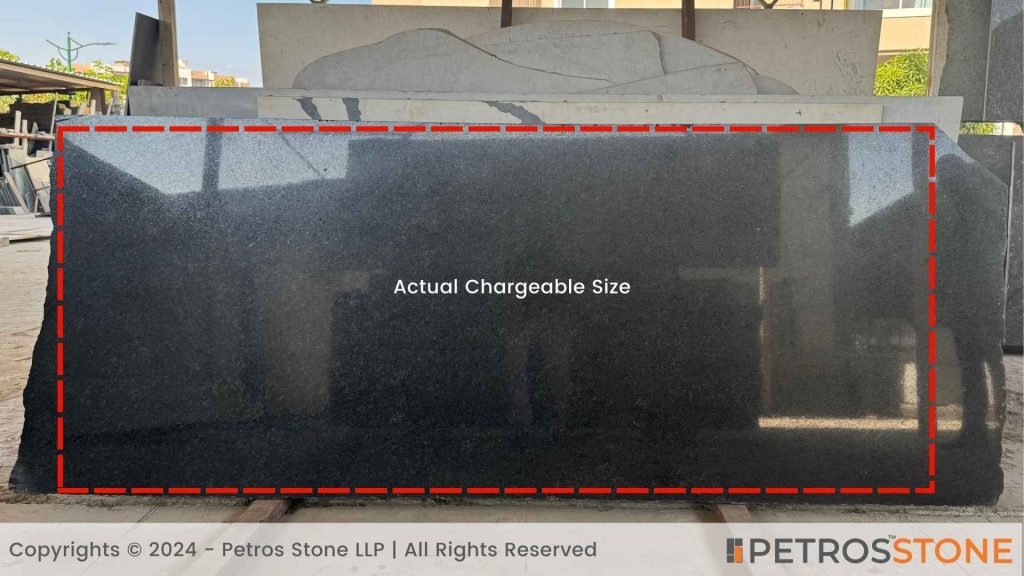

All measurements for the area of the slab must be made such that you only pay for the largest right angled rectangle that could be cut from the slab. By that what we mean is you only pay for a right angled rectangle that fits in the granite slab. This is especially important for slabs that are not perfectly cut into rectangles or have some kind of chipping or edge damage.

Here is an illustration to explain this concept:

How to Measure the Thickness of Granite?

Vernier Caliper

A Vernier caliper is a measuring instrument that is used to determine thickness of the granite. Digital Vernier caliper work the best. That said, a measuring tape can work just fine.

Measuring Tape

A measuring tape is a device that is used to measure distance or length of granite. The numbers on the tape measure are split into upper and lower divisions. The lower row is measured in centimeters (CM), while the upper row is measured in inches (inch).

How to Evaluate the Consistency of Granite/Quartz Thickness?

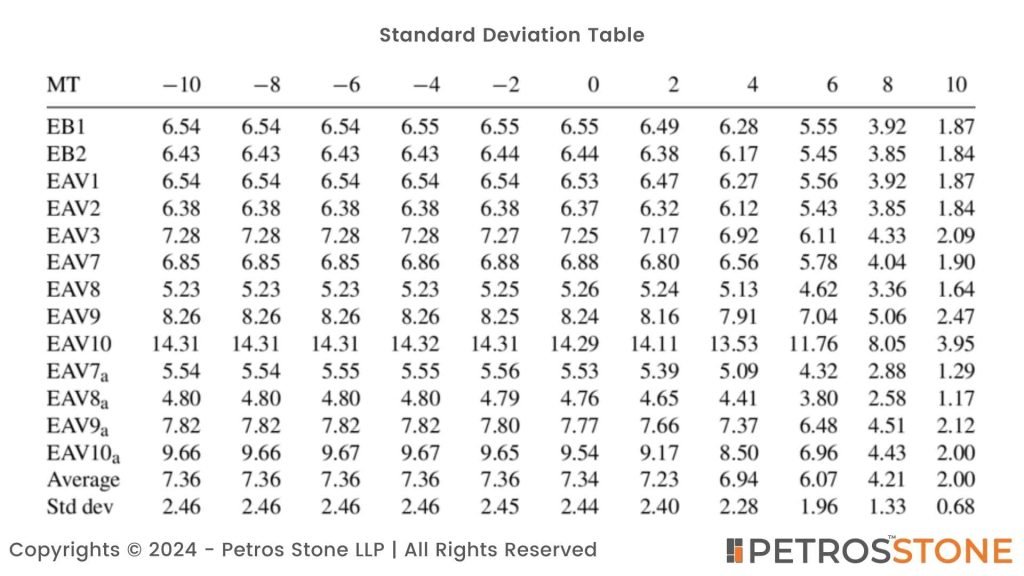

The standard deviation can be computed to assess the consistency of thickness across multiple measurements. This statistical method provides insight into the extent of variation from the average thickness.

A low standard deviation suggests that the measurements are closely concentrated around the mean, which indicates a consistent thickness.

Significant variability is suggested by a high standard deviation, which may be a cause for concern in applications that necessitate uniformity of thickness – for example floorings. Wall claddings. If this is not kept in mind, some slabs may appear to pop out of the surface, creating a very ugly and unfinished aesthetic if not creating cracks and ends over time.

How do we Measure the Polish Quality of Granite Slabs?

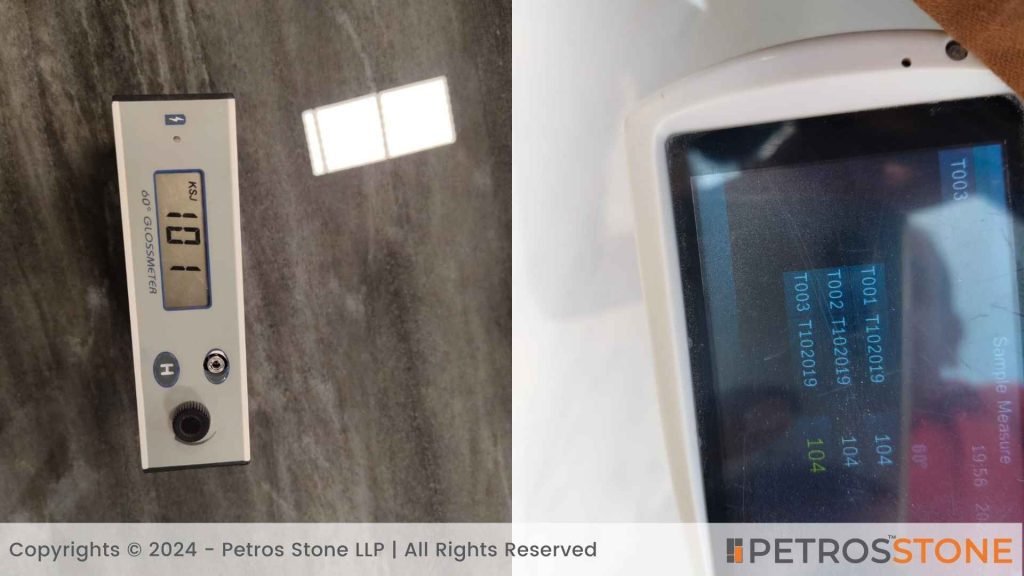

One can use a Gloss meter, also known as a “Glossometer”, to assess the polish quality of granite and marble slabs.

Gloss Meter

A gloss meter is a device that is employed to quantify the specular reflection (gloss) of a surface. The process of determining gloss involves projecting a beam of light onto a surface at a fixed intensity and angle and then measuring the quantity of reflected light at an equal but opposite angle.

In order to gauge the polishing of marble, terrazzo, and granite, a high-sensitivity gloss meter may be employed, which is a specialized instrument that precisely measures the reflection of light on the surface. The typical gloss meter has a range of 1 to 200, with 200 degrees representing the mirror reflection of light. A rating above 70 is considered a good reflection for granite/marble slabs and ratings above 100 are considered exceptional.

Want to know how to check the quality of quartz slab? read this article.

How to Check if the Marble Slabs have Cracks?

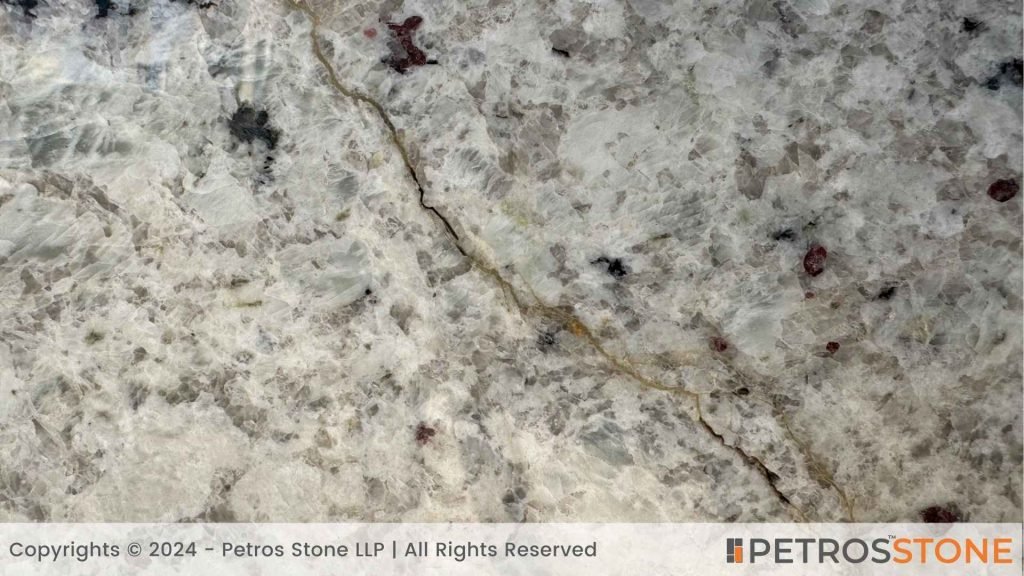

Before integrating the marble into your residence or project, it is essential to conduct a comprehensive inspection of the stone to identify any imperfections or cracks.

By inspecting for cracks, shine, colour variations, and patterns, you can guarantee that the marble or granite you purchase is of the highest quality and will endure the passage of time.

The identification of cracks in marble necessitates the utilization of suitable instruments and a keen eye. During the inspection procedure, the following are some practical methods for identifying cracks:

Visual Examination of Cracks in Natural Stone

Conduct a meticulous examination of the marble’s surface in well-lit conditions. Inspect the item for any visible fractures, chips, or irregularities.

Tapping of Cracks in Natural Stone

Use a wooden mallet or your knuckles to touch the marble surface gently. Solid areas will emit a clear, resonant tone, while cracked areas will generate a dull and hollow sound.

Moisture Test

Apply a few droplets of water to the marble surface. Cracks or fissures will rapidly absorb water, while sealed and undamaged regions will repel it.

Ultrasonic Testing

A more sophisticated method of identifying cracks and voids within marble can be employed without causing any injury through ultrasonic testing.

How do you Measure the Weight of Granite Slabs?

The precise weight of a granite slab for kitchen countertops, stairs, or flooring can be difficult to ascertain due to the varying layout and space requirements. Instead, granite is generally measured in square feet, a globally recognized unit of measurement. The thickness of the granite countertop is a critical factor to consider, as thicker slabs are denser and, as a result, weigh more without increasing the square footage.

The majority of granite slabs are typically either 2 centimeters (cm) or 3 centimeters (cm) thick. Although denser granite slabs are available, they are less prevalent and generally more costly.

Density of Granite Slabs

It is imperative to inspect bends or curved sections in granite slabs to guarantee the quality and integrity of the material, mainly when it is utilized for applications such as architectural features, countertops, or other applications that require a consistent and seamless appearance.

The following is a method for analyzing the bends in granite slabs:

What is the appropriate method for examining the bends in granite slabs?

• Your venture calls for a heavy-duty fabric with advanced energy and sturdiness.

• You’re running on high-visitor’s regions, outdoor installations, or large surfaces.

• You prioritize advanced performance functions which includes intense warmth and weather resistance.

Testing by Assessing it from a Particular Angle

The most effective method for detecting bends in granite slabs is to position two slabs with their polished surfaces facing each other and lean them toward each other. In this approach, two granite slabs are chosen and placed in close proximity to one another, ensuring that their polished edges are in alignment to form a straight line when viewed from the side.

Any bend or curvature that exists is readily apparent due to the visible gap or misalignment that occurs at the point where the slabs should meet in perfect alignment as one is gradually tilted toward the other. The severity of the bend can be deduced from the gap’s magnitude. Through meticulous observation, it is possible to determine which slab is responsible for the observed opening.

Utilizing a Spirit Level Bar

A bubble level or spirit level is a device that is employed to ascertain whether the surface being measured is horizontal or vertical. The bubble tube’s reading is recorded after the level is positioned on a flat and approximately level surface.

This reading indicates the degree to which the surface is parallel to the horizontal plane, as determined by the level, which is currently undetermined in terms of its accuracy. After this, the spirit level is rotated 180 degrees in the horizontal plane, and an additional reading is recorded. If it is accurate, the level will indicate the same orientation with respect to the horizontal plane.

How to Check if Granite Slabs have any Artificial Coloring?

• The colour of a natural granite slab should be consistent.

• Rub the granite with a cloth that has been soaked in paraffin or kerosene to determine whether it is natural. Reject the slab promptly if the cloth exhibits colour.

• This implies that the granite contains an artificial colour.

• Artificial coloring can be employed to conceal the stone’s imperfections, including fissures, lines, and patches.

• Occasionally, it may even undergo a complete transformation in appearance. Scratch the stone’s surface using an instrument or a material that is rated 6+ on the Mohr’s Hardness scale.

• This indicates that the stone has an artificial colour coating if it does not leave a mark.

Additional Quality Tests for a Granite/Marble Slab

As technology advances, each porcelain and sintered stone are evolving to comprise smart functionalities, together with integrated heating or self-cleansing surfaces. Environmental concerns are also using innovation, with producers specializing in sustainable practices, decrease carbon footprints, and recycled content material to fulfill the growing demand for eco-friendly materials.

Stain Resistance

Conduct a stain resistance test by applying a small quantity of common domestic liquids (e.g., coffee or oil) to the granite surface and observing whether or not they leave a stain. Granite of superior quality ought to be impervious to staining.

Lemon Test

Granite exhibits specific reactions to lemons that can be used to evaluate its quality. If the granite absorbs the lemon juice, it indicates that the stone is porous or has not been appropriately polished. The presence of white discoloration on the surface after applying lemon droplets suggests a high concentration of calcite. It is advisable to steer clear of slabs that exhibit these reactions.

Color and Pattern

Granite is a natural stone, and as such, it is common for it to exhibit variations in color and pattern. Ensure that these variations are within the permissible ranges for your project.

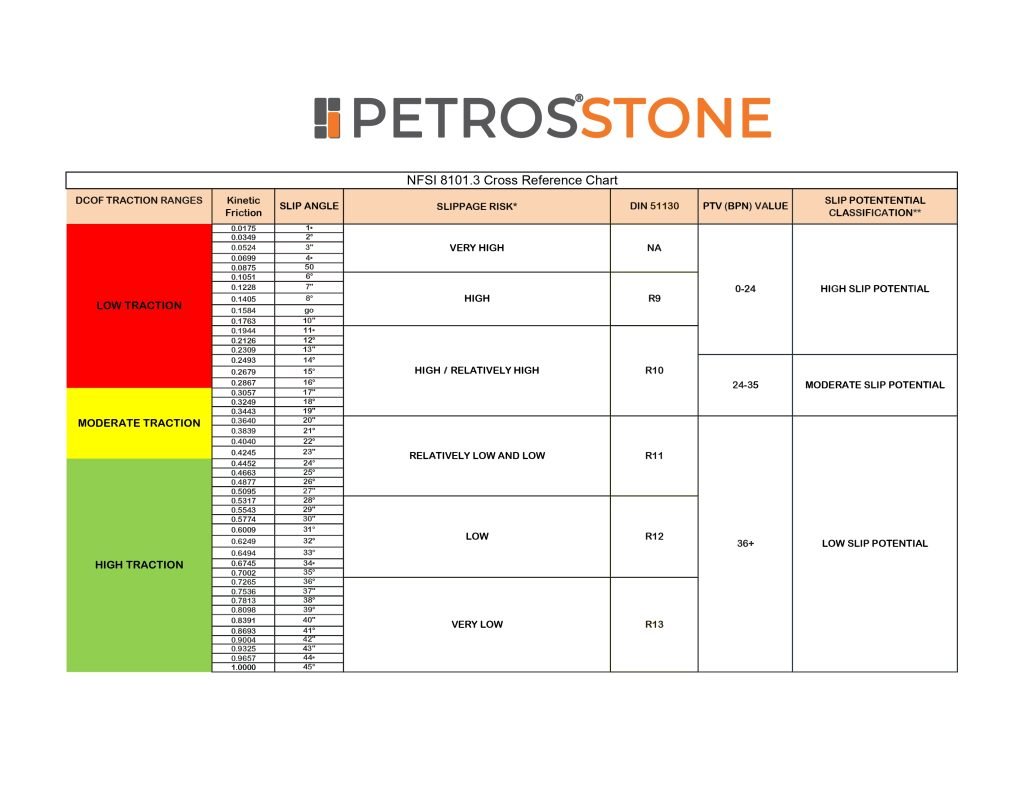

The Pendulum Tester

The Pendulum Tester, which includes a rubber slider, is the most frequently used and specified method of measuring slip resistance. Slip resistance is a critical performance attribute that is essential for people’s safety. R11 is considered as a good slip resistance for granite.

Here is a chart of slip resistance

Conclusion

A meticulous eye for quality selection is necessary when selecting granite or marble, that why here at Petros® our slabs are curated and sorted a team with more than 20 years of experience.

The finest slabs are processed from the finest blocks and the quest for quality begins at the source. We here at Petros® believe in educating the customers so they can not only understand quality but also be able to assess it.

Feel free to get in touch for a free consultation, quote, and get a detailed understanding from our experts here at Petros®. Visit https://petrosstone.com/ or call +91-8446360361 and WhatsApp

Hi, I’m Shivangi,

With years of experience in the architecture and design space, I write to bridge the gap between material knowledge and practical application. At Petros® Stone, I create content that highlights the beauty, function, and impact of natural stones, helping homeowners and professionals make confident design decisions.

Explore my LinkedIn profile to learn more about my work!

Brown Granite

White Galaxy Granite

Blue Bahia Granite

Silver Cloud Granite

Black Pearl Granite

Dallas White Granite